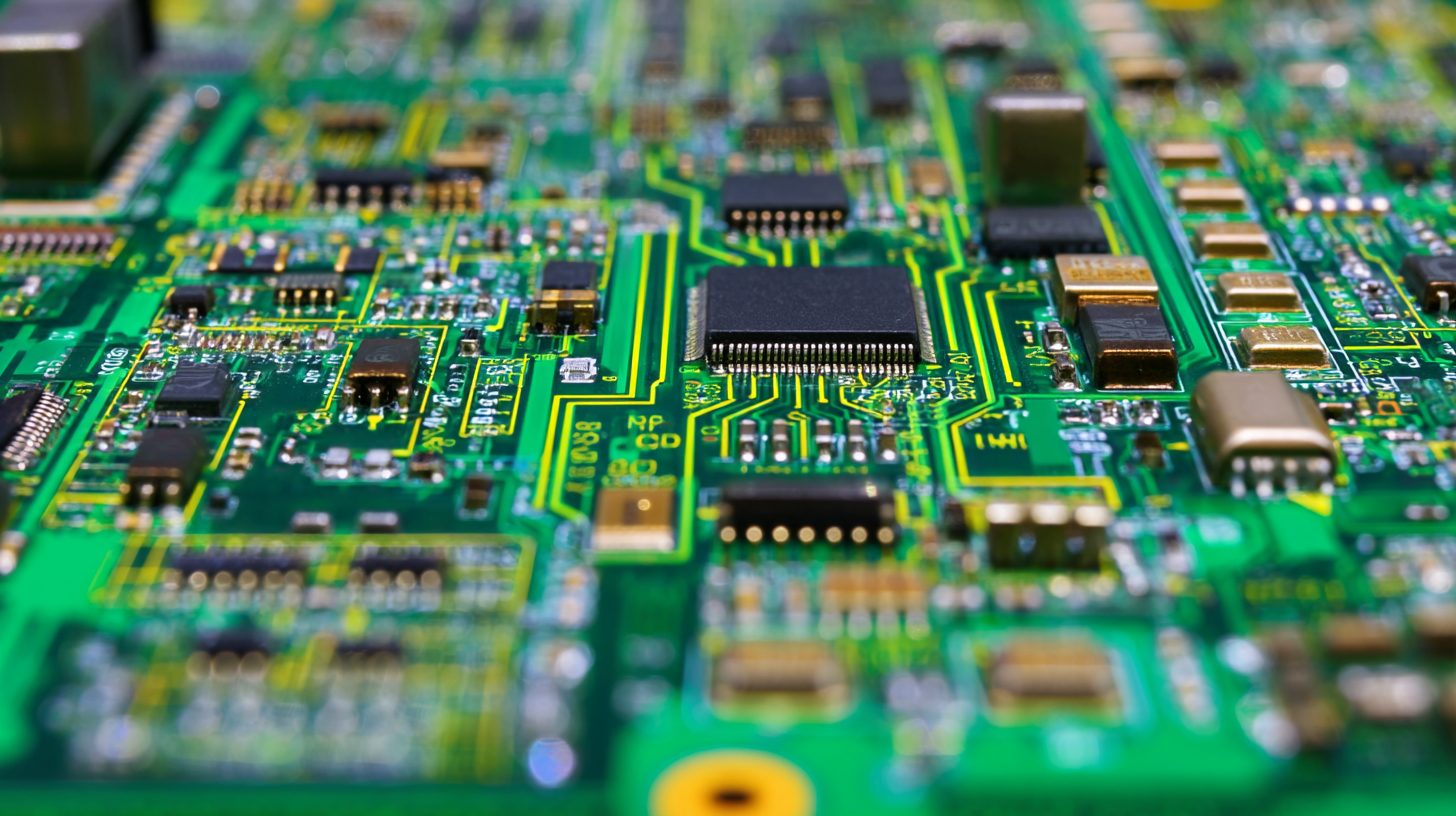

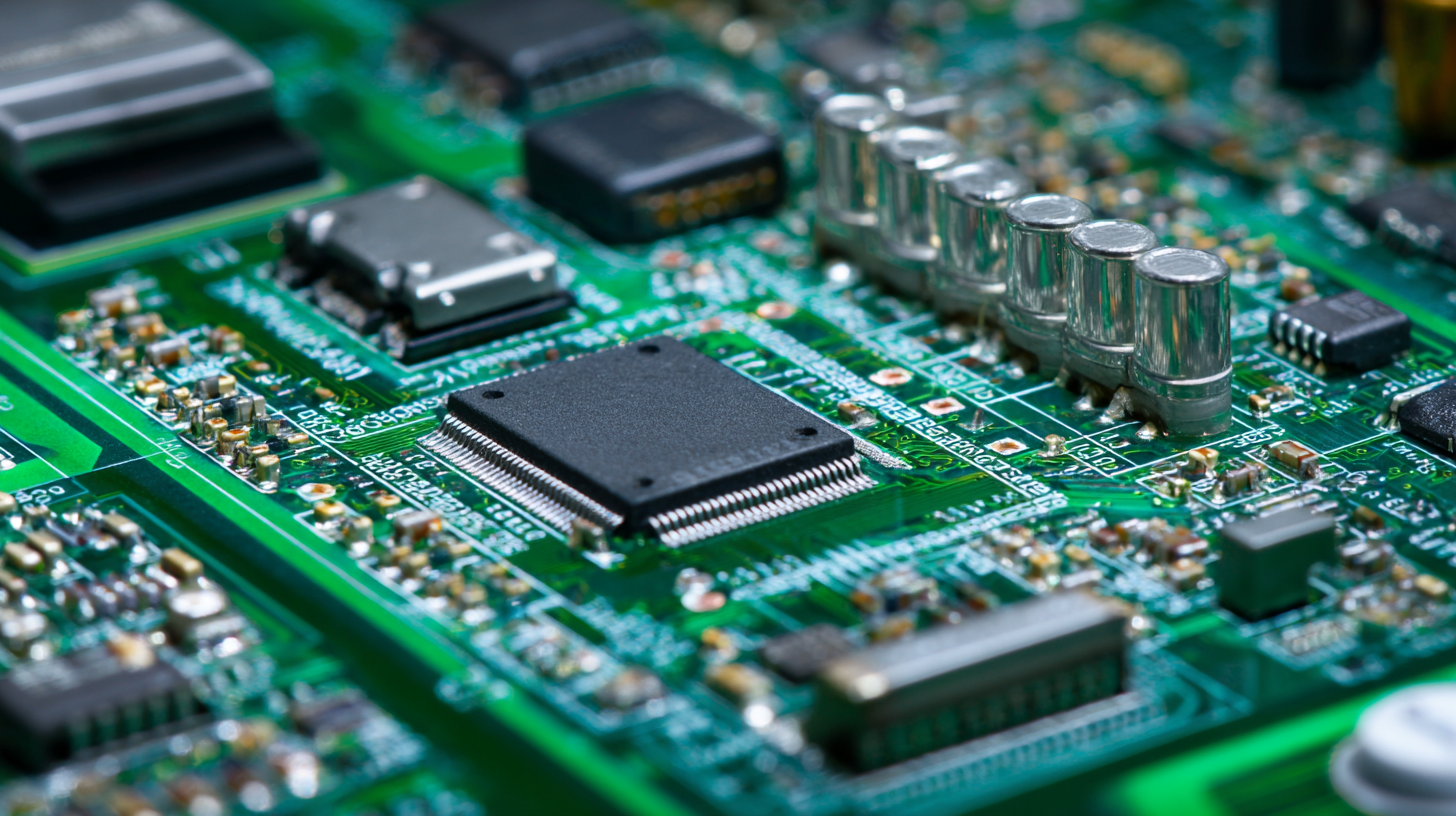

30+ Years of Experience in PCB Design and Manufacturing

In the fast-paced world of electronics innovation, the demand for efficient and rapid prototyping solutions has led to the emergence of quick turn PCB manufacturing as a pivotal process. According to a report by Research and Markets, the global quick turn PCB market is projected to grow significantly, reaching approximately $9 billion by 2025, driven by the accelerating need for quick turnaround times and increased design complexity.

Quick turn PCB services offer the advantage of drastically reducing lead times, enabling engineers and developers to test and iterate their designs more rapidly than traditional manufacturing methods allow. With advancements in technology, including automated fabrication and enhanced design software, quick turn PCB is set to play a crucial role in shaping the future of electronic product development, empowering innovators to bring their ideas to life in record time.

The rise of Quick Turn PCB manufacturing has dramatically transformed the prototyping landscape in the electronics industry. This shift allows companies to minimize the time from design to production, enabling faster iterations and reducing time-to-market. According to a report from IPC, the global PCB market is expected to reach $85 billion by 2027, with Quick Turn services growing at a significant rate as businesses increasingly prioritize rapid prototyping to stay competitive.

As companies embrace Quick Turn PCB processes, they can leverage advanced technologies that facilitate quicker design cycles. For instance, utilizing automated systems can reduce production lead times from weeks to days. A recent study indicated that 75% of manufacturers cite shorter lead times as a key reason for investing in Quick Turn capabilities. This development is becoming essential for firms looking to innovate swiftly and respond to market changes with agility.

Tips: When engaging with Quick Turn PCB services, ensure your design files are optimized for manufacturability to avoid potential production delays. Additionally, maintain clear communication with your PCB manufacturer to streamline revisions and adjustments throughout the prototyping process. Finally, regularly review and update your prototyping strategies to take full advantage of emerging technologies and trends in this rapidly evolving field.

The demand for Quick Turn PCB (Printed Circuit Board) services is on the rise, significantly shaping the landscape of rapid prototyping in electronics. Industry statistics indicate a compound annual growth rate (CAGR) of over 10% in the Quick Turn PCB market. This growth can be attributed to the increasing need for shorter product development cycles and the relentless pace of technological advancement. More companies are turning to Quick Turn PCB solutions to keep up with consumer demands and innovate at a faster rate.

When considering Quick Turn PCB services, it’s essential to choose a provider with a proven track record. Look for vendors that offer a full suite of services, from initial prototype design to final production, which can streamline the development process and reduce time to market.

Additionally, leveraging advanced technologies, such as automated manufacturing and real-time quality control, can significantly enhance the reliability of your PCBs. Always inquire about the company’s quality assurance protocols to ensure your prototypes meet industry standards and perform effectively in their intended applications. Engaging in regular communication with your PCB supplier can also help address potential design issues early in the process, ultimately leading to a smoother and more efficient project timeline.

| Year | Market Size (USD Billion) | Growth Rate (%) | Key Application Areas |

|---|---|---|---|

| 2021 | 1.2 | 10.5 | Consumer Electronics |

| 2022 | 1.5 | 12.0 | Automotive |

| 2023 | 1.9 | 14.0 | Telecommunications |

| 2024 | 2.4 | 16.5 | Medical Devices |

| 2025 | 3.0 | 18.0 | Industrial Applications |

In the fast-paced world of electronics innovation, Quick Turn PCB (Printed Circuit Board) services have emerged as a crucial factor in reducing time-to-market. According to a recent report by the IPC (Association Connecting Electronics Industries), companies that utilize quick turn prototyping can decrease their product development cycles by up to 30%. This accelerated pace allows businesses to respond swiftly to market demands and consumer needs, facilitating quicker feedback loops and more iterative design processes.

The benefits of Quick Turn PCB extend beyond mere speed. These services often come with lower upfront costs, as they eliminate the need for expensive tooling associated with traditional manufacturing methods. Additionally, the flexibility offered by quick prototype iterations enables engineers to experiment with new designs without the significant financial burden. A study from the IEEE suggests that organizations employing rapid prototyping techniques experience a 25% increase in overall innovation output.

Tips for Maximizing the Benefits of Quick Turn PCB:

In the rapidly evolving landscape of electronics innovation, the development of prototypes plays a crucial role in bringing ideas to life. Quick turn PCB manufacturing stands out as a significant advancement when compared to traditional PCB manufacturing. The key difference lies in the speed at which prototypes can be produced. Quick turn PCB services often allow for turnaround times of just a few days, whereas traditional methods may take weeks to provide even initial samples. This expedited process not only saves time but also accelerates the feedback loop between design and functional testing, ultimately leading to faster market deployment.

However, speed is not the only factor to consider. Traditional PCB manufacturing often benefits from established processes and economies of scale, making it suitable for large production runs. These methods can deliver cost-effective solutions for high-volume orders, while quick turn PCB services typically cater to smaller batches and rapid iterations. As a result, teams focused on innovation and iterative design may find quick turn PCB services more aligned with their needs, enabling them to explore multiple design options without the constraints of longer lead times or significant upfront costs. This comparative analysis highlights the evolving methodologies in PCB manufacturing and their implications on the future of electronics prototyping.

The rapid evolution of technology is steering the quick turn PCB market towards unprecedented innovations. One of the primary trends is the integration of AI and machine learning into the PCB design process. These technologies not only enhance design efficiency but also minimize human error, allowing for faster iterations and adjustments. By leveraging algorithms that predict performance outcomes and automatically adjust layouts, manufacturers can significantly reduce prototyping times while maintaining high-quality standards.

Another notable trend is the rise of advanced materials that enhance the thermal and electrical performance of PCBs. Innovations such as flexible PCBs and high-frequency materials are catering to the growing demand for lightweight, compact, and efficient electronic devices. This shift is enabling the development of more sophisticated applications in sectors like consumer electronics, automotive, and healthcare. As designers seek to create more intricate and multifunctional PCBs, these material advancements are crucial in supporting the rapid prototyping needed for future innovations.