30+ Years of Experience in PCB Design and Manufacturing

PCB assembly is a critical process that serves as the backbone of modern electronic devices, supporting an ever-expanding range of applications across various industries. According to a report by the IPC, the global PCB assembly market is projected to reach USD 83 billion by 2026, driven by the increased demand for consumer electronics, automotive systems, and medical devices.

As the complexity of electronic products grows, understanding the nuances of PCB assembly becomes essential for manufacturers striving to enhance product performance and reliability. This process not only involves the precise placement of components but also necessitates stringent quality control measures to ensure functionality and durability.

With advancements in technology, such as automation and improved materials, PCB assembly is evolving rapidly, making it essential for stakeholders to stay informed about best practices and emerging trends to maintain a competitive edge in this dynamic market.

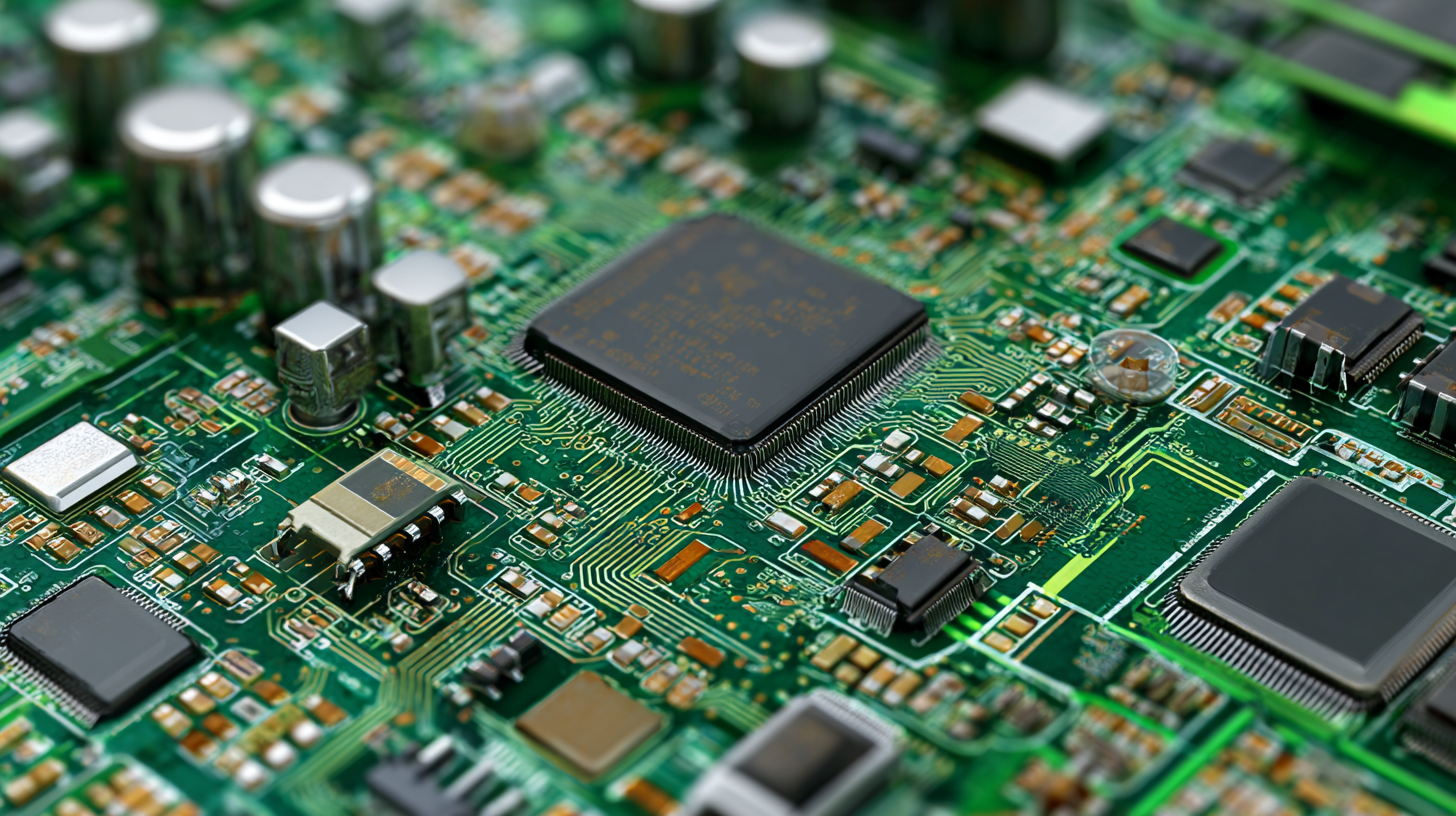

PCB assembly plays a crucial role in the electronics manufacturing process, serving as the backbone for a wide array of modern devices. From smartphones to medical equipment, the functionality and reliability of these gadgets hinge on the quality of their printed circuit boards (PCBs). The assembly process involves meticulous placement of electronic components onto the PCB, ensuring optimal connections and performance. It is within this intricate assembly that the electronic circuit design transforms into tangible products, ready for consumers.

PCB assembly plays a crucial role in the electronics manufacturing process, serving as the backbone for a wide array of modern devices. From smartphones to medical equipment, the functionality and reliability of these gadgets hinge on the quality of their printed circuit boards (PCBs). The assembly process involves meticulous placement of electronic components onto the PCB, ensuring optimal connections and performance. It is within this intricate assembly that the electronic circuit design transforms into tangible products, ready for consumers.

Tips: When selecting a PCB assembly service, consider their experience in your specific industry. This expertise can significantly impact the efficiency and reliability of your end product. Additionally, always request samples of their previous work to assess the quality and precision of their assembly process.

The essential role of PCB assembly also extends to the development of new technologies. As electronic devices become more compact and complex, the demand for advanced PCB assembly techniques increases. Automated processes, such as surface mount technology (SMT), have revolutionized how we approach assembly, allowing for faster production times and reduced costs without sacrificing quality.

Tips: Keep abreast of emerging assembly technologies that might enhance your product's performance. Investing in innovative PCB assembly methods can lead to better product reliability and customer satisfaction.

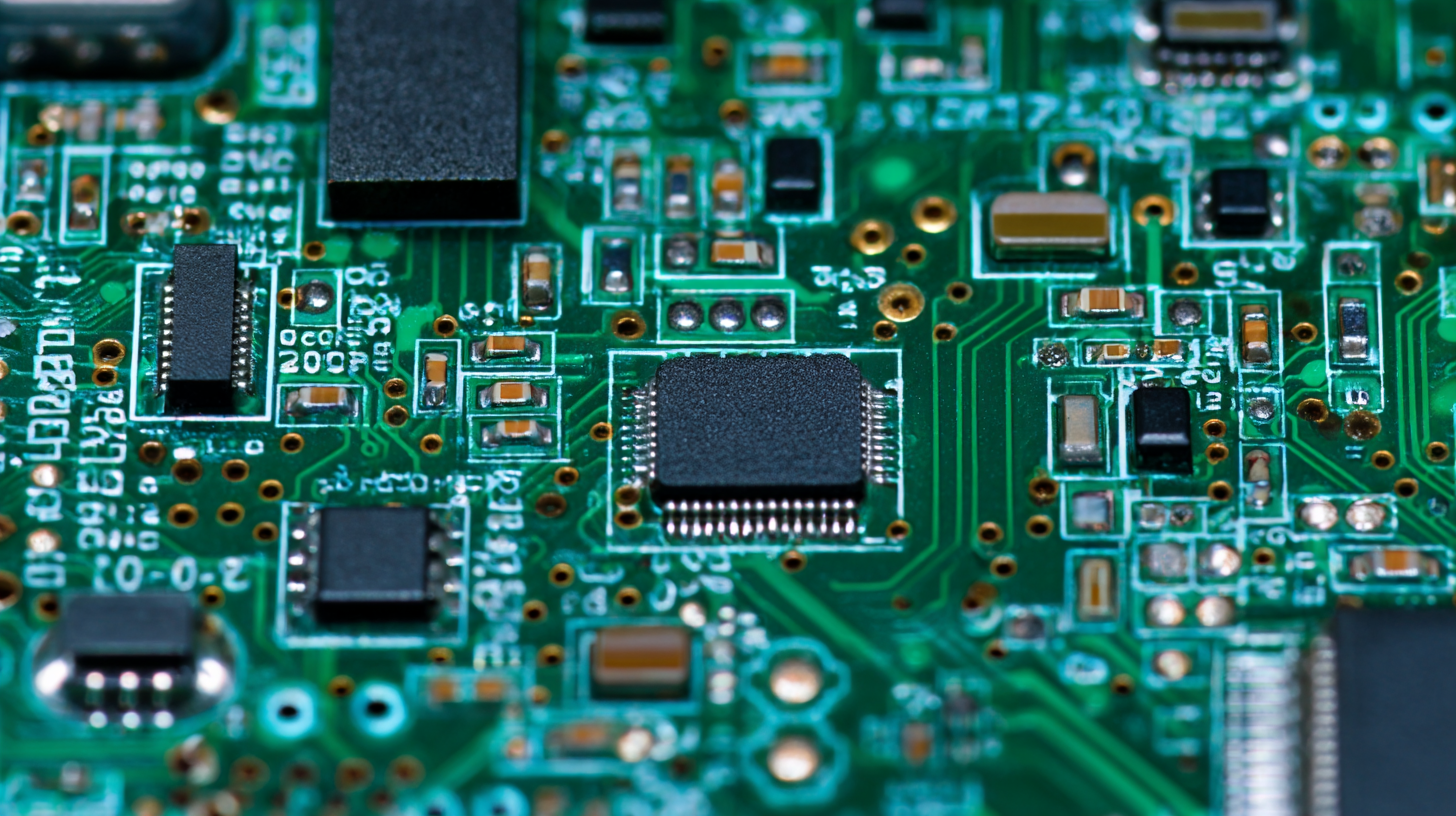

Printed Circuit Boards (PCBs) form the backbone of modern electronic devices, with their assembly process involving a variety of key components and materials. The primary materials used in PCB assembly include substrates, conductive copper layers, and solder, each playing a pivotal role in ensuring the functionality and durability of electronic devices. According to a report by Research and Markets, the global PCB market is projected to reach USD 70 billion by 2026, showcasing the increasing demand for sophisticated electronic products.

Substrates such as FR-4 (a glass-reinforced epoxy laminate) offer excellent electrical insulation and thermal stability, making them a popular choice in PCB manufacturing. Meanwhile, the copper traces allow for the conduction of electrical signals between various components mounted on the board. The soldering process, which can be accomplished using lead or lead-free solder, is critical for creating a robust electrical connection. As per IPC's report on soldering standards, lead-free solder usage has risen significantly, with approximately 80% of new products manufactured with lead-free processes as of 2020, in response to regulatory pressures and environmental considerations. These materials and methods are essential for ensuring quality, reliability, and performance in the ever-evolving landscape of electronics.

This chart illustrates the percentage usage of key components in the PCB assembly process, highlighting the significance of each component in modern electronic devices.

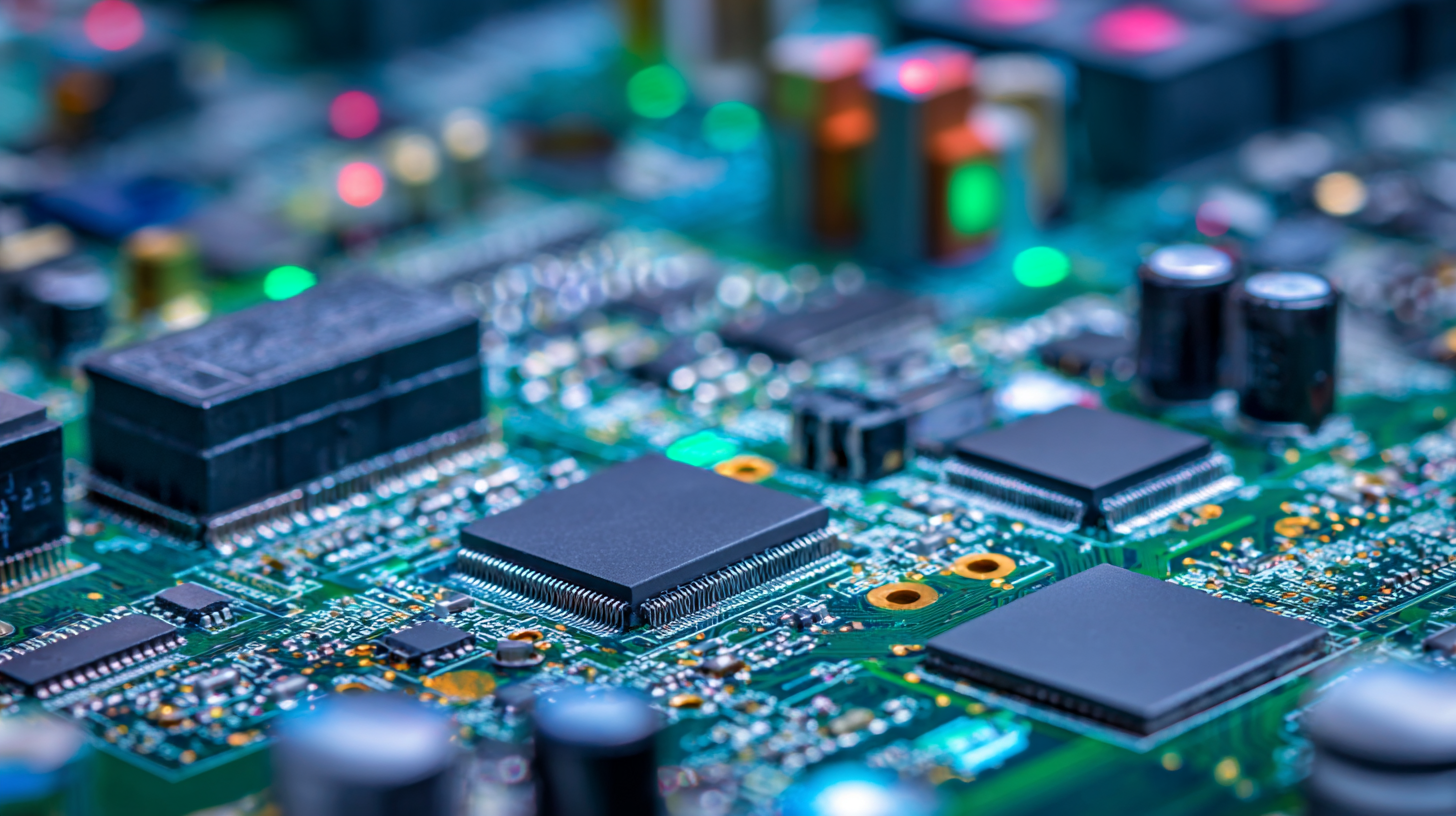

The process of PCB fabrication is fundamental to the performance and reliability of modern electronic devices. Various techniques, such as subtractive and additive manufacturing, play a crucial role in determining the final quality of the printed circuit board. Subtractive methods typically involve etching away layers of copper from a laminate, which can lead to intricate designs but may also generate waste. In contrast, additive techniques build the circuit layer by layer, offering greater precision and potential for complex geometries. The choice of fabrication method directly impacts the efficiency, cost, and sustainability of electronic production.

Furthermore, advancements in PCB fabrication technologies, including laser direct imaging and automated assembly, are enhancing the scalability and efficiency of PCB production. These innovations not only streamline manufacturing processes but also enable the integration of advanced functionalities within smaller footprints. The impact of these techniques extends beyond production efficiency; they also influence electrical characteristics, thermal management, and durability of the final products. As electronics continue to evolve, the fabrication techniques used in PCB manufacturing are increasingly critical to meeting the demands of the next generation of devices.

Quality control and testing methods play a pivotal role in PCB assembly, significantly impacting the reliability and performance of modern electronic devices. According to a report by IPC, the global electronics manufacturing services (EMS) market, which includes PCB assembly, is forecasted to reach $580 billion by 2025. This growth underscores the need for rigorous quality control processes to ensure that the intricate assemblies meet required specifications and standards.

Effective testing techniques, such as Automated Optical Inspection (AOI) and X-ray inspection, are vital in identifying defects early in the production process, reducing the risk of failures in the field.

Furthermore, the implementation of Six Sigma methodologies in PCB assembly has been shown to reduce defects by up to 50%, enhancing overall product quality. A study from the American Society for Quality (ASQ) notes that companies using statistical process control (SPC) in their manufacturing processes experience less than 1% defective products. This emphasis on quality not only improves product durability but also builds consumer trust and satisfaction in an increasingly competitive marketplace.

As technology continues to advance, the focus on quality control in PCB assembly will remain essential for ensuring that electronic devices function reliably in critical applications.

The landscape of PCB assembly technology is rapidly evolving, driven by advancements in miniaturization and automation. Future trends indicate a shift towards more sophisticated manufacturing methods, such as automated optical inspection (AOI) and robotics, which enhance precision and efficiency. This not only reduces production times but also minimizes human errors, essential for the increasingly complex electronic devices that consumers demand.

As companies continue to innovate, sustainability will become a critical focus in PCB assembly processes. Embracing eco-friendly materials and recycling practices will help reduce the environmental footprint associated with electronic waste. The integration of smart technologies also promises to boost the industry, allowing for real-time monitoring and data analytics to optimize workflows and resource usage.

**Tips:** When considering PCB assembly services, look for manufacturers that prioritize quality control measures, such as rigorous testing protocols, to ensure reliable performance. Additionally, staying informed about emerging technologies can help companies adapt and leverage new capabilities to remain competitive in the marketplace.