30+ Years of Experience in PCB Design and Manufacturing

In today's fast-paced electronics industry, securing a competitive PCB quote is crucial for project success. As the demand for complex circuit boards continues to rise, the market for PCB manufacturing is expected to grow substantially, with a projected increase in revenue to reach $79.12 billion by 2026, according to a recent market research report by Mordor Intelligence. This underscores the importance of optimizing the quoting process to ensure both cost-effectiveness and high-quality results.

Industry expert Dr. Emily Zhang, a senior analyst at Circuit Research Labs, emphasizes the significance of transparency in obtaining accurate PCB quotes: "A well-documented PCB quote not only helps manufacturers provide precise pricing but also aligns the project objectives with client expectations." By adhering to best practices for soliciting quotes, clients can navigate the complexities of PCB procurement more efficiently, ensuring that they receive the best possible value while minimizing delays and misunderstandings.

As we delve into the top tips for getting the best PCB quote, understanding the nuances of the quoting process will enable stakeholders to forge stronger partnerships with manufacturers and ultimately achieve successful project outcomes.

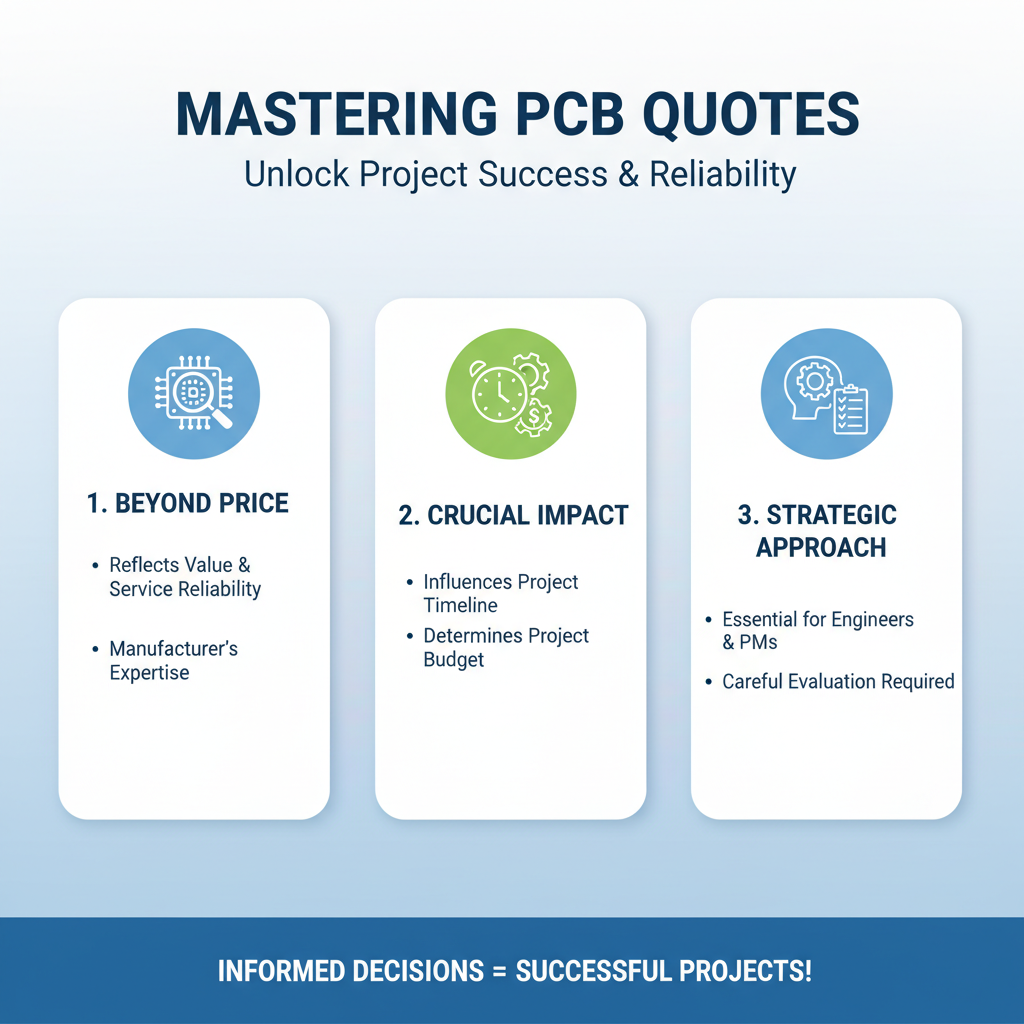

When embarking on an electronics project, obtaining accurate PCB quotes is crucial. These quotes serve as more than just price estimates; they reflect the value and reliability of the services provided by PCB manufacturers. Understanding the intricacies of PCB quotes can significantly influence the project's timeline and budget, making it essential for engineers and project managers to approach this process with care.

Moreover, a well-detailed PCB quote can reveal the manufacturer's capabilities and quality standards. By closely examining the specifics, such as materials, technology, and lead times included in the quote, project stakeholders can gauge whether the manufacturer aligns with their project's requirements. In this competitive industry, the cost-effectiveness of a quote can also directly impact production decisions, underscoring the necessity of securing the best possible PCB quote for the successful realization of any electronic endeavor.

When seeking the best quote for your PCB project, understanding the key factors that influence pricing is crucial. Firstly, the complexity of the design plays a significant role. More intricate layouts with multiple layers, smaller components, and specialized materials tend to drive costs higher due to increased manufacturing time and precision requirements. Additionally, the size of the PCB can affect pricing; larger boards often require more materials and longer processing times, contributing to a higher overall cost.

Another important factor is the quantity of PCBs you are ordering. Generally, manufacturers offer lower per-unit prices when larger quantities are ordered due to economies of scale. However, the urgency of the project should also be considered, as expedited services can significantly increase costs. Furthermore, the choice of materials and finishes, such as the type of solder mask or surface treatment, can also impact pricing. By carefully evaluating these elements, you can obtain a more accurate estimate and ensure your project remains within budget while meeting quality standards.

When seeking the best PCB quote for your project, comparing offers from different manufacturers is crucial. Start by outlining your specific requirements, including material, layer count, and manufacturing processes, as this will provide consistent parameters when requesting quotes. Ensure that you ask each company for a detailed breakdown of their pricing, highlighting costs related to materials, labor, and shipping. This detailed insight will help you understand the value behind each quote and facilitate an apples-to-apples comparison.

Once you have obtained the quotes, evaluate additional factors such as production timelines, quality certifications, and customer service. A lower price may seem appealing, but it could come with hidden costs like longer lead times or inferior quality. Look for manufacturers that provide guarantees or have positive reviews regarding their customer support. By weighing both cost and value-added services, you can make an informed choice that aligns with your project’s needs, ensuring both efficiency and quality in your PCB production.

| Tip No. | Tip Description | Key Considerations | Estimated Cost Impact |

|---|---|---|---|

| 1 | Clarify Your Specifications | Make sure to detail your material, size, layer count, and finish. | High impact if specifications are vague. |

| 2 | Request Multiple Quotes | Compare at least 3-5 different manufacturers. | Moderate impact; can lead to better pricing. |

| 3 | Check for Hidden Costs | Inquire about shipping, setup fees, and tooling costs. | High impact; can significantly alter total cost. |

| 4 | Evaluate Delivery Times | Timeframes can vary greatly between manufacturers. | Moderate impact; delays can incur extra costs. |

| 5 | Assess Manufacturer's Capabilities | Ensure they can meet your technical requirements. | High impact; wrong choice can lead to failure in production. |

| 6 | Inquire About Quality Certifications | Look for certifications like ISO or IPC standards. | Moderate impact; ensures quality assurance. |

| 7 | Consider Bulk Ordering | Ordering in larger quantities can reduce per-unit costs. | High impact; can make significant savings. |

| 8 | Check for Design Support | Support in design can help prevent costly mistakes. | Moderate impact; design errors can be expensive to rectify. |

| 9 | Obtain References and Reviews | Ask for feedback from previous clients of the manufacturer. | Moderate impact; builds trust and credibility. |

| 10 | Negotiate Terms | Don't hesitate to negotiate pricing and terms. | High impact; can lead to better agreements and savings. |

When requesting a PCB quote, providing comprehensive and accurate information is essential to ensure you receive the best possible pricing and service. A recent industry report from IPC found that nearly 30% of PCB cost overruns are attributed to incomplete specifications during the quoting process. Therefore, it is crucial to include detailed information about your project's requirements. This includes specifying the desired materials, layer counts, and minimum trace widths, all of which directly affect production costs and capabilities.

Additionally, including information on the intended application of the PCB can help manufacturers suggest optimal solutions that fit your cost and performance needs. According to a study by Hughes-Peters Group, clear communication of project goals and timelines can lead to an average reduction in lead times by up to 25%. Moreover, understanding complex requirements like surface finish, solder mask options, and testing needs can enable suppliers to provide you with more tailored quotes, ensuring the project stays within budget while meeting quality standards. Providing this essential information upfront not only streamlines the quoting process but also fosters a collaborative relationship with the manufacturer, leading to better outcomes.

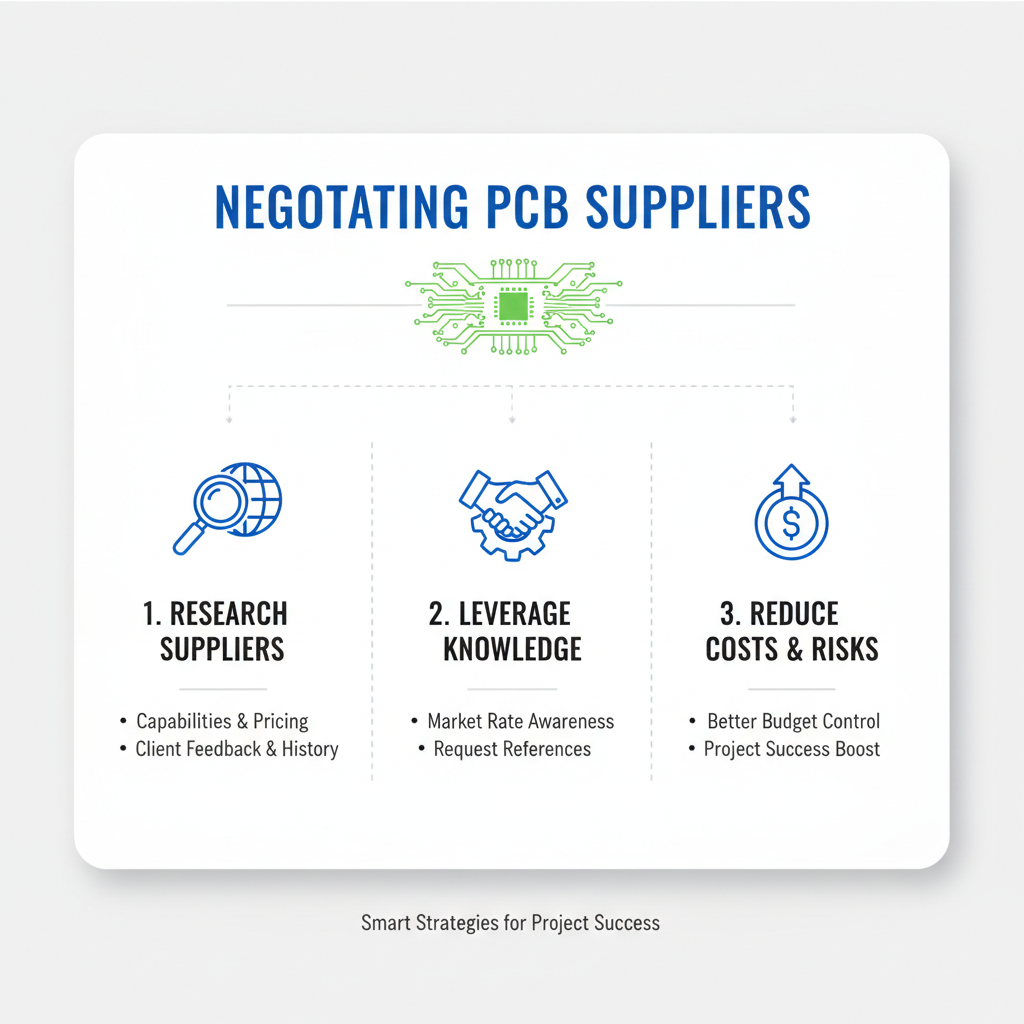

Negotiating with PCB suppliers can significantly impact your project’s budget and overall success. One effective strategy is to conduct thorough research on potential suppliers. Understanding their capabilities, pricing structures, and previous client feedback can not only arm you with vital information but can also strengthen your negotiating position. When you approach a supplier, demonstrate awareness of market rates and ask for references to establish credibility and rapport.

Additionally, leveraging bulk orders can be advantageous. Suppliers are often more willing to reduce prices for larger quantities due to reduced production costs. However, be careful to balance quality with quantity; ensure that you are not compromising on your specifications just to save costs. Establish clear communication, expressing your needs and concerns, while also being open to their suggestions. This bidirectional dialogue can lead to customized solutions that benefit both parties, potentially resulting in better pricing and improved terms.