30+ Years of Experience in PCB Design and Manufacturing

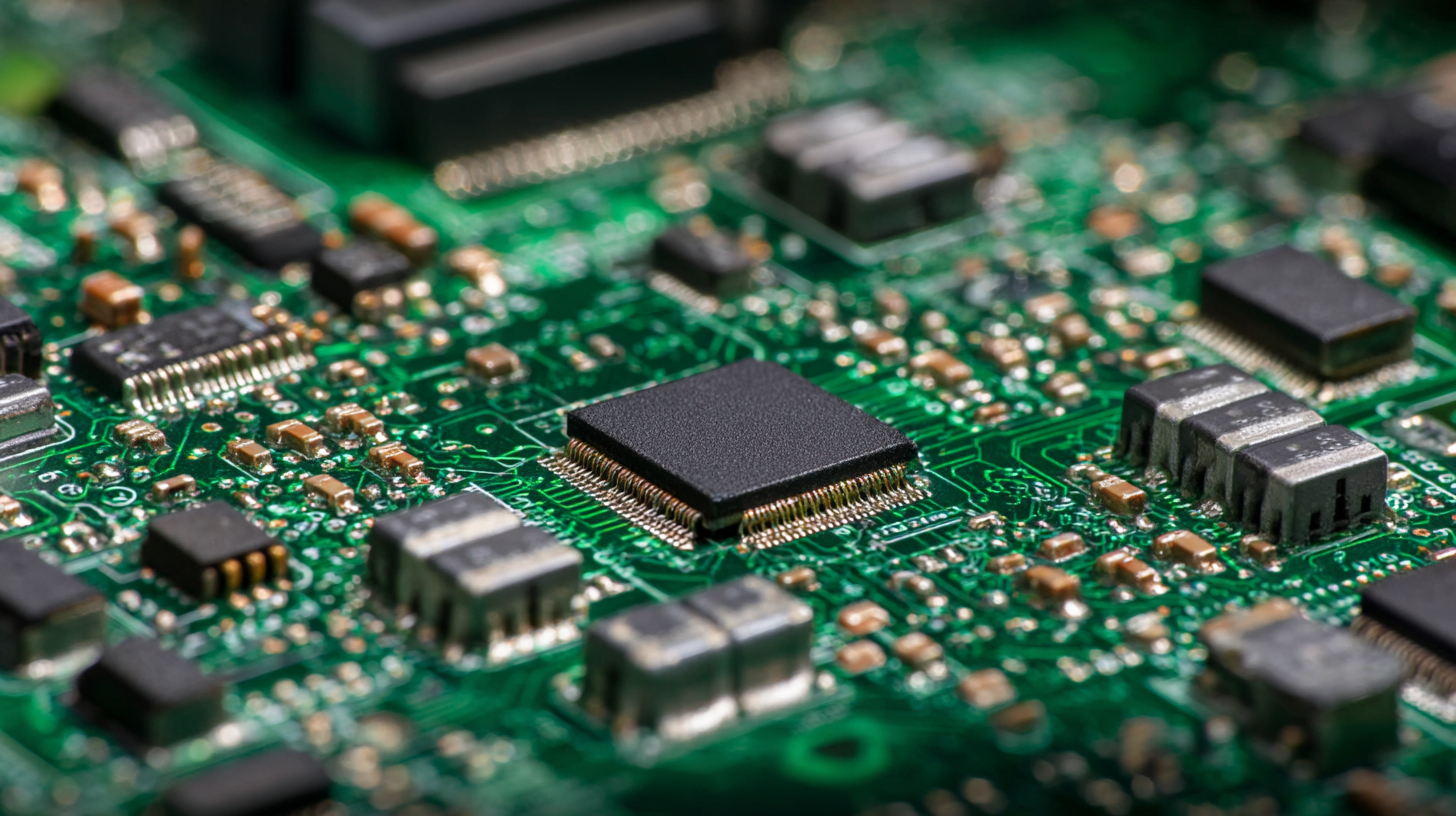

The global electronics manufacturing landscape has undergone significant transformations in recent years, with printed circuit board assembly (PCBA) emerging as a pivotal component driving innovation and efficiency in the industry. As electronic devices become increasingly complex and ubiquitous, the demand for reliable and high-quality PCBA solutions is at an all-time high. This surge is fueled by advancements in technology, evolving consumer preferences, and the pressing need for cost-effective production methods. Understanding the rise of printed circuit board assembly not only sheds light on the mechanics of modern electronics manufacturing but also highlights the critical role that PCBA plays in enhancing performance and functionality across various sectors.

This article aims to explore the essential processes involved in PCB assembly, the factors contributing to its growth, and the implications for manufacturers and consumers alike, providing a comprehensive overview of how this process is shaping the future of global electronics.

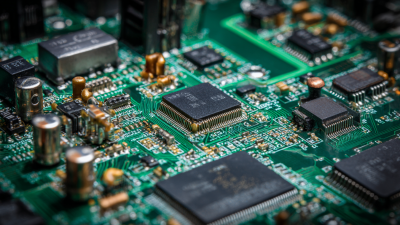

The evolution of printed circuit board (PCB) assembly techniques has been a crucial factor in the transformation of electronics manufacturing. Initially, the process was labor-intensive, relying heavily on manual soldering and basic assembly methods. However, with the advent of surface mount technology (SMT) in the 1980s, the industry saw a significant shift. SMT allowed for smaller components to be placed directly onto the surface of PCBs, enhancing the density and functionality of electronic devices while also streamlining production processes.

As technology advanced, automated machinery began to dominate PCB assembly lines. Innovations such as pick-and-place machines and automated optical inspection (AOI) systems have improved precision and speed, reducing error rates and production costs. Modern techniques emphasize not only efficiency but also flexibility, enabling manufacturers to adapt quickly to changing market demands.

**Tips:** When considering PCB assembly options, evaluate the specific needs of your project, such as component size and complexity. Investing in high-quality automated inspection tools can significantly reduce defects, ensuring a more reliable final product. Additionally, staying informed about the latest assembly techniques can provide a competitive edge in this rapidly evolving industry.

The rise of printed circuit board (PCB) assembly in global electronics manufacturing can be attributed to several key factors that are driving its growth in various markets. As technology continues to evolve, the demand for more sophisticated electronic devices has surged, necessitating advanced PCB assembly processes. These processes are not only crucial for enhancing the performance and reliability of electronics but also play a vital role in meeting the increasing consumer expectations for compact and efficient devices.

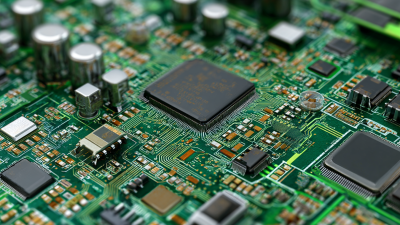

Additionally, regional diversification of manufacturing has contributed to the expansion of the PCB assembly market. OEMs are seeking cost-effective production solutions, leading to the establishment of assembly facilities in countries with lower labor costs. This strategic move allows companies to optimize their supply chains while maintaining high-quality standards. Furthermore, the rise of IoT and smart technologies has created new opportunities for PCB assembly, driving innovation and investment across the globe. As this trend continues, the market is poised for significant growth between 2024 and 2032, with various segments focusing on diverse applications tailored to meet the needs of different industries.

The printed circuit board (PCB) assembly sector is fundamental to global electronics manufacturing, characterized by rapid technological advancements and the need for efficiency. Optimizing PCB assembly processes is essential for producers looking to enhance productivity and reduce costs. Implementing streamlined operations can lead to measurable benefits in both speed and quality.

Tips for Optimization:

One effective practice is adopting automation in assembly lines. Automated soldering and component placement not only speed up the process but also minimize human error, ensuring consistency across production. Another best practice is to implement a robust quality control mechanism early in the assembly process. By detecting defects at an early stage, manufacturers can reduce waste and rework, leading to a more efficient flow and higher profitability.

In addition to automation and quality checks, investing in staff training can significantly improve assembly outcomes. Skilled workers can quickly adapt to new technologies and methodologies, ensuring operational efficacy. Empowering employees with the knowledge and skills necessary for their roles leads to a more agile and responsive production environment, further driving efficiency and innovation in PCB assembly.

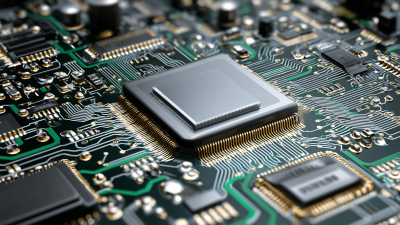

The landscape of printed circuit board (PCB) assembly is rapidly evolving, driven by emerging technologies that are reshaping the global electronics manufacturing sector. Innovations such as automation, artificial intelligence (AI), and the Internet of Things (IoT) are enhancing efficiency and precision in the PCB manufacturing process. Automated machinery enables faster production cycles and minimizes human error, while AI algorithms optimize design and assembly processes, leading to higher-quality outputs at reduced costs.

Moreover, the integration of IoT devices into PCB assembly lines facilitates real-time monitoring and data analysis, allowing manufacturers to anticipate issues before they escalate into significant problems. This interconnectedness not only improves operational transparency but also enables predictive maintenance, ultimately increasing the lifespan of manufacturing equipment. As these technologies continue to advance, they will play a crucial role in meeting the growing demand for more complex and compact electronic devices, ensuring that PCB assembly remains at the forefront of innovation in global electronics manufacturing.

| Technology | Impact on PCB Assembly | Adoption Rate (2023) | Forecast Growth (2024-2028) |

|---|---|---|---|

| Automation | Increases efficiency and reduces manual labor | 65% | 15% annually |

| IoT Integration | Enhances connectivity in electronics | 58% | 20% annually |

| Advanced Materials | Improves thermal management and durability | 70% | 12% annually |

| Eco-Friendly Processes | Reduces environmental impact of PCB manufacturing | 50% | 25% annually |

The complexities in the PCB assembly supply chain are becoming increasingly apparent, particularly in regions such as Thailand, where new local hiring regulations have posed significant challenges for Taiwanese manufacturers. The requirement for foreign-invested firms to employ at least 70% local staff complicates efforts to establish and expand operations, thus necessitating innovative solutions to align with these regulations while maintaining efficiency and productivity.

Moreover, the overall electronics manufacturing landscape is evolving with advancements in technology and market demands, which introduces both opportunities and challenges. The trend of rising Panel-Level Packaging is indicative of a shift towards more compact and efficient designs, while the integration of AI and other technologies into manufacturing processes necessitates a focus on enhancing supply chain resilience. As companies navigate these dynamics, it's essential to develop strategic approaches that not only comply with local requirements but also leverage emerging trends to strengthen their market position.