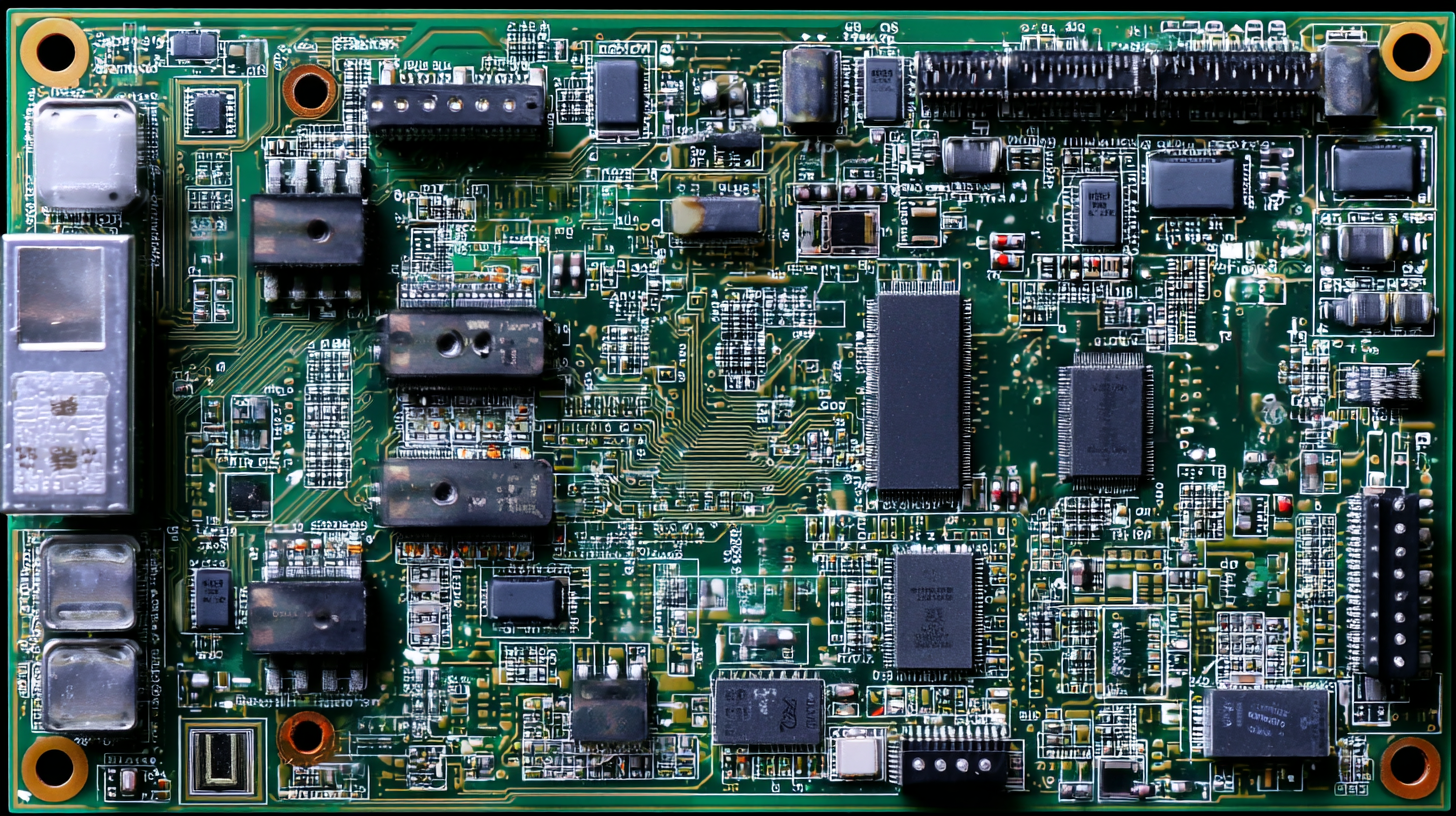

30+ Years of Experience in PCB Design and Manufacturing

The rapid evolution of technology has propelled the electronics industry into a new era, with PCB boards at the forefront of innovation. According to a recent report by ResearchAndMarkets, the global PCB market is expected to reach $82.92 billion by 2026, growing at a CAGR of 4.51% from 2021. This growth is largely driven by advancements in consumer electronics, automotive electronics, and the expanding use of PCB boards in various applications such as smartphones, wearable devices, and IoT systems.

As we delve into the top innovations in PCB board technology for 2023, it is essential to highlight how these developments not only enhance performance but also address the increasing demand for miniaturization and efficiency. Innovations such as flexible PCBs, high-frequency materials, and embedded component technologies are redefining design possibilities and setting new standards for durability and functionality. This evolution is not merely a trend but a necessary response to the complex needs of modern electronic systems that require more compact and reliable components.

In this article, we will explore ten groundbreaking PCB board innovations that are set to revolutionize the electronics landscape in 2023. By examining these advances, we will uncover how they contribute to smarter, faster, and more efficient electronic devices, ultimately shaping the future of the industry.

The rise of next-generation flexible PCBs is reshaping the landscape of wearable technology, providing the foundation for a range of innovative applications. These advanced circuits enable devices to bend and flex, ensuring comfort and usability for users across various settings—from fitness enthusiasts tracking their health metrics to individuals utilizing smart textile solutions for wellness monitoring. Recent developments in self-powered energy sources, such as piezoelectric and thermoelectric materials, are enhancing the efficiency and autonomy of these devices, allowing them to harness energy from body movements or environmental heat.

Tips: When exploring flexible PCBs for wearable tech, consider the materials and energy conversion technologies involved. Understanding how these elements work together can aid in selecting the right solution for specific applications. Additionally, keep an eye on emerging research in flexible semiconductors and intelligent textiles, as these innovations are set to further enhance the capabilities of wearable devices.

The future of wearable tech looks bright, driven by these flexible innovations. As the technology becomes more ubiquitous, users can expect more integrated experiences, where clothing and accessories not only serve traditional purposes but also interact intelligently with their environments. By advancing the integration of electronics into our daily lives, flexible PCBs are paving the way for smarter, more responsive health and fitness solutions.

In 2023, the integration of innovative thermal management solutions has become pivotal for enhancing the performance of printed circuit boards (PCBs). As electronic devices continue to operate at higher speeds and increased power densities, effective heat dissipation strategies are essential. According to a report by ResearchAndMarkets, the global thermal management market is projected to reach $14.1 billion by 2025, growing at a CAGR of 4.5% from 2020. This rising demand underscores the importance of advanced thermal management technologies in maintaining the reliability and functionality of high-performance boards.

One of the most significant innovations in thermal management is the adoption of advanced materials like thermal interface materials (TIMs) and phase change materials (PCMs). These materials not only improve thermal conductivity but also enhance the overall efficiency of heat transfer in compact electronic designs. Additionally, innovative cooling solutions such as embedded cooling technologies and micro-channel heat sinks offer new avenues for managing heat. A study published in the IEEE Transactions on Components, Packaging and Manufacturing Technology highlighted that designs incorporating these thermal management solutions can reduce operational temperatures by up to 30%, thereby extending the lifespan of electronic components and ensuring optimal performance under demanding conditions.

| Innovation | Type | Key Features | Benefits | Applications |

|---|---|---|---|---|

| Thermal VIA Technology | Thermal Management | Enhanced heat dissipation through optimized thermal vias | Improved thermal performance and reliability | High-performance computing, Power electronics |

| Cooling Embedded Traces | Thermal Management | Traces embedded within the board to cool critical components | Maximized space efficiency and cooling | Consumer electronics, Automotive |

| Graphene Heat Spreaders | Material Innovation | Use of graphene to enhance thermal conductivity | Outstanding heat distribution with minimal weight | Smart devices, Telecommunication |

| Nano-coating for Heat Resistance | Coating Technology | Nanotechnology-based coatings to enhance heat resistance | Increased longevity and durability of components | Industrial machinery, Aerospace |

| Hybrid PCB Materials | Material Innovation | Combination of different materials for thermal performance | Optimized performance in varying thermal conditions | Energy systems, Telecommunications |

| Active Cooling Solutions | Active Thermal Management | Incorporation of fans and thermal sensors | Real-time thermal regulation | Gaming consoles, High-end PCs |

| PCB Heat Pipes | Thermal Management | Transport heat away from critical components | Efficient heat transfer in compact designs | Telecom, Server farms |

| Micro-channel Cooling Systems | Active Thermal Management | Micro-channels designed into the PCB | High efficiency in cooling critical areas | High-performance computing, Medical devices |

| Thermal Interface Materials | Material Innovation | Advanced materials for optimal thermal conductivity | Better heat transfer between components | LED lighting, Consumer electronics |

In 2023, the electronics industry is witnessing a significant shift towards sustainable materials in printed circuit board (PCB) manufacturing, a movement that is crucial for reducing environmental impact. According to a recent report by the International Electronics Manufacturing Initiative (iNEMI), the PCB industry is projected to increase its adoption of eco-friendly materials by over 30% in the next five years. This change is driven by rising awareness of the ecological repercussions of traditional manufacturing processes, which often rely on toxic chemicals and non-biodegradable substances.

Some innovative materials being integrated into PCB designs include bio-based substrates and recyclable laminates. For instance, the use of plant-derived resins not only minimizes carbon emissions during production but also enhances the biodegradability of the product at the end of its lifecycle. A 2022 study by Research and Markets suggested that the global market for sustainable PCB materials will reach $8.1 billion by 2027, reflecting a compounded annual growth rate (CAGR) of 7.5%. Companies that embrace these innovations are not only fulfilling regulatory requirements but are also appealing to increasingly environmentally-conscious consumers. This transition to sustainable practices signifies a pivotal moment in the quest for a greener and more responsible electronics sector.

This chart illustrates the top innovations in PCB manufacturing focusing on sustainable materials and their impact on the environment. The data reflects the percentage reduction in environmental impact by adopting these innovations.

The rapid evolution of electronics in 2023 has been significantly influenced by advanced 3D PCB structures, which are redefined to enhance both space efficiency and functionality. Unlike traditional flat PCBs, these innovative designs utilize vertical stacking and intricate layering, allowing various components to occupy less surface area while improving connectivity. This spatial optimization is particularly beneficial in compact devices that demand high performance without bulk.

Integrating 3D PCBs not only maximizes space but also boosts thermal management and signal integrity, which are critical in today’s high-speed applications. By reducing the overall footprint of devices, manufacturers can create sleeker products that appeal to consumers and facilitate better heat dissipation through innovative layout designs. With these advancements, the potential for diverse applications expands, paving the way for smarter electronics that adapt to user needs.

Tips: When considering an upgrade to 3D PCBs, evaluate your design's specific space constraints and functionality requirements. Collaborating with PCB manufacturers early in the design phase can also unveil unique solutions tailored to your product needs. Lastly, keep an eye on materials that enhance thermal performance, as they play a crucial role in the longevity and efficiency of electronic devices.

The integration of AI-driven design tools is significantly transforming the landscape of PCB development in 2023. These advanced tools leverage machine learning and data analytics to enhance the design process, enabling engineers to create more efficient and compact circuit layouts. By automating repetitive tasks and eliminating human error, AI tools not only accelerate the design cycle but also allow for greater innovation in electronic components.

Moreover, AI technology fosters collaboration among design teams by providing real-time feedback and suggestions during the design process. As engineers work on intricate layouts, AI can predict potential issues or inefficiencies, suggesting optimizations that may not be immediately apparent. This leads to higher quality PCBs that meet the increasing demands for performance and miniaturization in modern electronics, ultimately paving the way for groundbreaking applications in various sectors, from consumer electronics to automotive systems.