30+ Years of Experience in PCB Design and Manufacturing

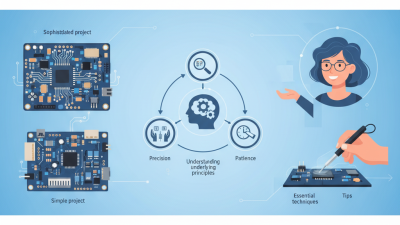

PCB assembly is a critical process in electronics manufacturing. This procedure involves connecting various electronic components onto a printed circuit board (PCB). Experts like John Doe, a veteran in the PCB assembly industry, emphasize its importance by stating, “Successful PCB assembly is the cornerstone of reliable electronics.”

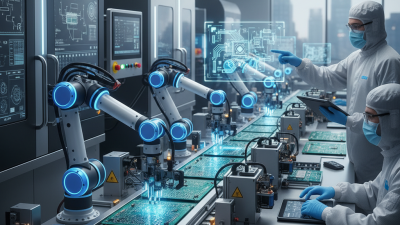

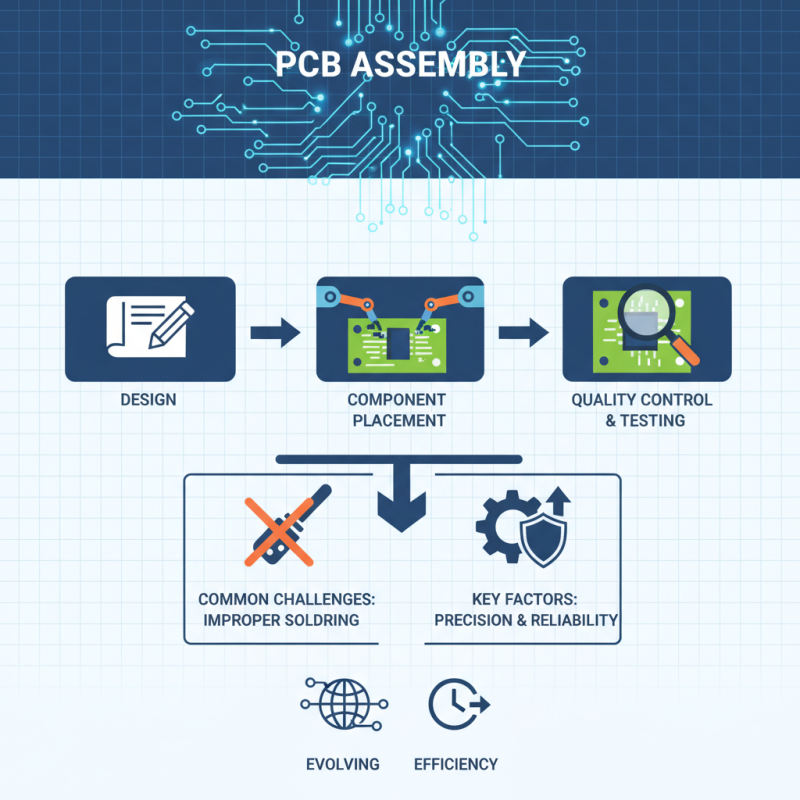

The process starts with designing the PCB layout. Then, components are placed on the board using precision machines. This method ensures accuracy and efficiency in production. However, assembly isn't always perfect. Mistakes can lead to malfunctions. For example, improper soldering can create issues that are hard to detect.

Several factors contribute to a flawless PCB assembly. Quality control and testing are essential at every stage. Despite advancements, there are still challenges. Workers must remain alert. Even minor errors can result in significant delays and costs. Exploring these aspects offers insights into the evolving world of PCB assembly.

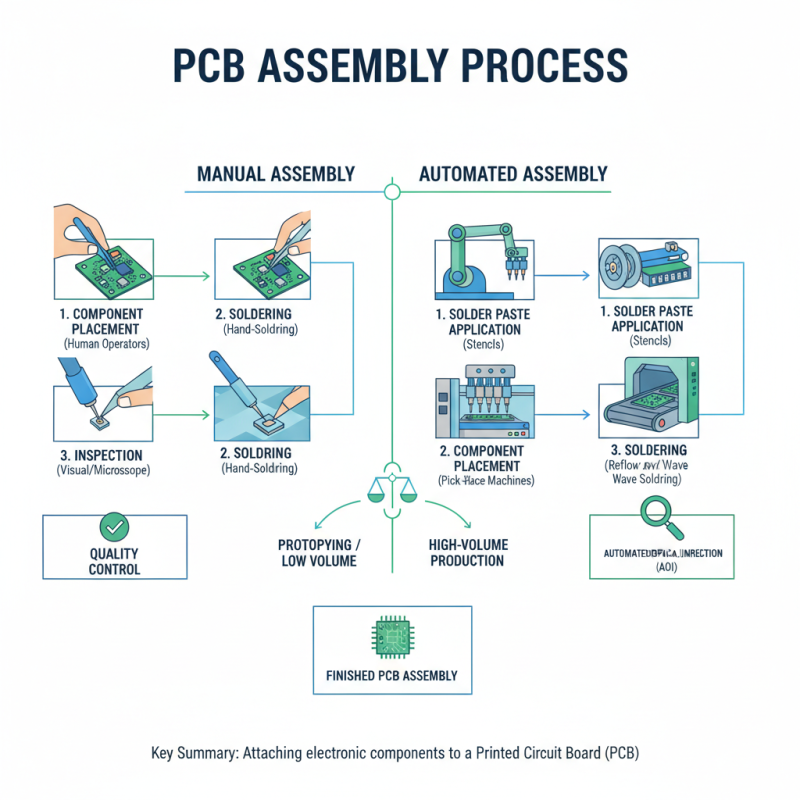

PCB assembly is a crucial process in the production of electronic devices. It involves attaching electronic components to a printed circuit board (PCB). This board serves as the foundation for connecting and supporting the components. The assembly can be done manually or through automated processes, each with its own advantages and challenges.

During the assembly process, various technologies are employed. Surface mount technology (SMT) is popular for its efficiency. Components are mounted directly onto the surface of the PCB. This method is fast and can save space. However, it requires precision and costly equipment. Through-hole technology (THT) is another option. It involves inserting component leads through holes in the PCB. This method can be more time-consuming and may lead to larger boards, adding complexity.

Furthermore, quality control is essential but often overlooked. Mistakes in assembly can lead to device failure. Common issues include misplaced components and soldering defects. Manufacturers must test PCBs thoroughly to avoid these pitfalls. Attention to detail is key, but even experienced teams can make errors. Continuous improvement is needed to enhance the assembly process and ensure reliability.

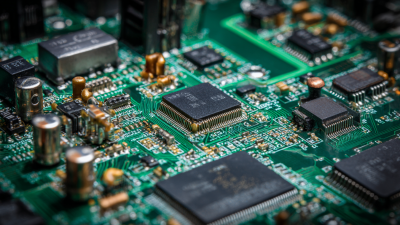

PCB assembly involves several key components that work together to create functional electronic devices. At the heart of this process is the printed circuit board (PCB) itself. A PCB serves as a foundation for mounting electronic components. It is typically made of fiberglass with conductive pathways etched onto its surface. These pathways connect various components, allowing for electrical signals to flow.

Next are the electronic components. Resistors, capacitors, and integrated circuits are just a few examples. Each component has a specific role. Resistors limit current flow, while capacitors store energy. Integrated circuits pack multiple functions into a compact form. Proper placement and secure soldering of these components to the PCB are crucial. Missing or misaligned parts can lead to malfunction.

Finally, the assembly process itself plays a vital role. This includes surface mount technology (SMT) and through-hole technology. SMT allows for components to be placed directly onto the surface of the PCB. This method improves efficiency but requires precision. On the other hand, through-hole assembly involves inserting component leads into holes. Each method has its benefits and limitations. Factors like cost, complexity, and the intended use of the device influence the choice of assembly method.

| Component | Description | Function |

|---|---|---|

| PCB (Printed Circuit Board) | A board made of insulating material with conductive traces | Provides the physical base for components and electrical connections |

| Solder Mask | A protective layer applied to the PCB surface | Prevents solder from flowing to unwanted areas |

| Electronic Components | Devices like resistors, capacitors, ICs, etc. | Perform various electrical functions in circuits |

| Silkscreen Layer | Printed markings on the PCB | Aids in identifying components' positions and values |

| Via | Metalized holes that connect different layers of a PCB | Facilitates multilayer connections |

| Solder | A fusible alloy used to join metal surfaces | Creates strong electrical connections between components |

The PCB manufacturing process begins with the design stage. Engineers create detailed schematics and layouts. Software tools, like CAD, are often used to visualize the board. According to a 2022 market report, the PCB industry reached nearly $70 billion, highlighting its significance.

Next, raw materials are chosen carefully. Copper-clad laminates are essential for circuit formation. Often, substandard materials lead to failures or inefficiencies. A study by IPC found that improper material selection causes up to 30% of PCB defects. This is a critical aspect that requires thorough evaluation.

After preparing the materials, the etching process removes unwanted copper. This step requires precision. Over-etching can result in damaged circuits. Lastly, assembly involves soldering components to the board. Inconsistent solder quality can lead to performance issues. Engineers continually seek ways to mitigate these risks, but challenges remain. Continuous assessment and improvement are crucial in a rapidly evolving industry.

This chart illustrates the time spent in each stage of the PCB assembly process. The process includes design, fabrication, assembly, testing, and inspection, highlighting the average hours required for each phase.

PCB assembly is a complex process involving several key steps to create functional electronic devices. The process begins with procurement of materials. High-quality printed circuit boards (PCBs) and components are essential. According to a recent industry report, about 35% of production defects stem from poor component quality. This highlights the significance of materials in the assembly line.

Next, the process includes stencil printing. Solder paste is applied to the PCB's pads. Accurate application is critical. Any inconsistency can lead to weak connections or solder bridges. During this stage, a misalignment of even 0.1 mm can affect the entire assembly. After printing, pick and place machines position the components. This automation increases efficiency but can also introduce errors if calibrated poorly.

The soldering stage follows, typically involving reflow or wave soldering methods. This step solidifies connections between the components and the PCB. Yet, it comes with challenges. Temperature fluctuations can cause defects like tombstoning, where components lift off one side. Industry surveys indicate that as many as 20% of assemblies face issues during soldering, underscoring the need for stringent process controls. Each step requires careful attention to minimize risks and enhance reliability.

Quality control is crucial in PCB assembly. It ensures that each board functions correctly and meets industry standards. According to a 2022 IPC report, defects in PCBs can lead to significant financial losses, estimated at $2.5 billion annually across the sector. Implementing thorough quality control processes can reduce these defects significantly.

Effective quality control involves several steps. First, incoming materials are inspected rigorously. Any discrepancies can lead to issues down the line. Visual inspections, as well as automated testing systems, play a vital role here. However, these methods are not foolproof. Human error can still creep in during manual inspections.

In addition, ongoing monitoring during the assembly process is essential. Regular checks can help identify problems early. This proactive approach is necessary, as the average cost of rework in PCB assembly can reach up to 20% of the total assembly cost. Continuous quality improvement must focus on training staff and investing in better technology to minimize mistakes. Companies must reflect on their quality practices to remain competitive.