30+ Years of Experience in PCB Design and Manufacturing

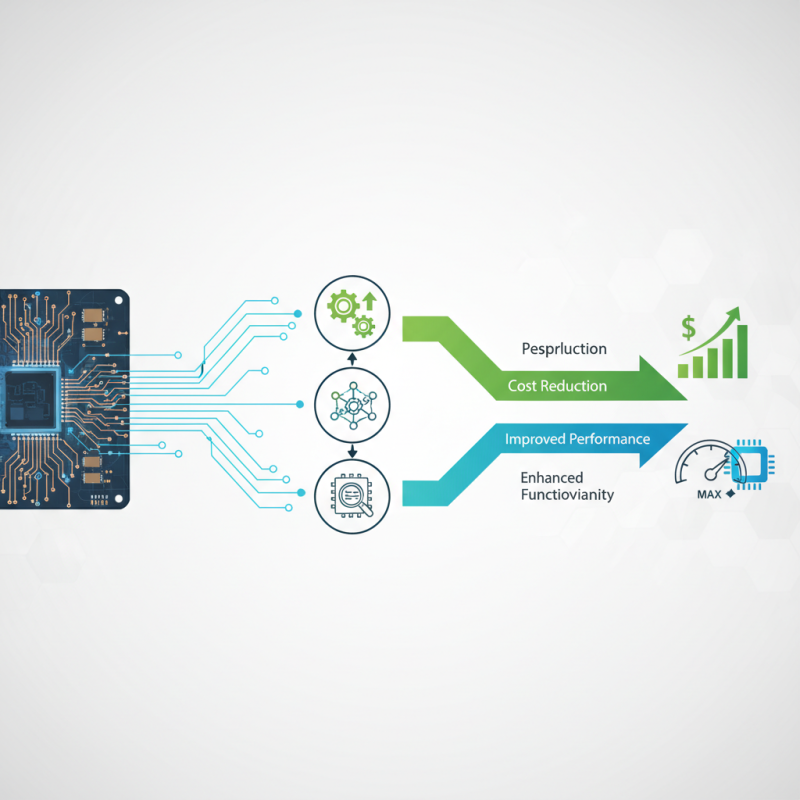

The optimization of printed circuit board assembly (PCBA) has become essential in today’s fast-paced electronics industry, where performance and cost-efficiency directly impact a company's competitiveness. According to a recent report published by the IPC (Association Connecting Electronics Industries), the global market for PCBA is projected to reach $75 billion by 2026, underscoring the growing demand for effective assembly processes. In this landscape, it is imperative for manufacturers to explore innovative techniques that enhance the overall functionality of their products while keeping costs under control.

Industry experts emphasize the importance of adopting best practices in PCBA to achieve these goals. Dr. Emily Huang, a renowned expert in electronic manufacturing, has stated, "The key to success in printed circuit board assembly is to streamline processes and leverage advanced technologies that reduce waste and improve quality." This encapsulates the core objective for businesses aiming to stay ahead; the integration of automation, real-time monitoring, and design for manufacturability can lead to significant improvements in both performance and cost management. As companies navigate the complexities of global supply chains and varying consumer demands, prioritizing optimization in their PCBA processes will be critical for long-term sustainability and success.

Printed Circuit Board (PCB) assembly is a critical process that serves as the backbone for modern electronic devices. Understanding the basics of PCB assembly is essential for manufacturers aiming to optimize performance and cost-efficiency. In essence, PCB assembly involves mounting electronic components on a board, which can be either surface mount technology (SMT) or through-hole technology. According to a recent report from Research and Markets, the global PCB market is expected to reach over $100 billion by 2025, driven by the rapid advancements in electronics and the growing demand for smaller and more efficient devices.

A key factor in optimizing PCB assembly is understanding the nuances of component placement and soldering processes. For instance, the implementation of automated pick-and-place machines can significantly enhance the accuracy and speed of component placement, reducing assembly times by as much as 30%. Moreover, data from IPC—Association Connecting Electronics Industries—indicates that improper soldering techniques can lead to up to 70% of PCB failures during operation, emphasizing the need for rigorous quality control and testing protocols during the assembly process. By focusing on these foundational aspects, manufacturers can not only improve assembly efficiency but also minimize defect rates, ultimately leading to better performance and lower production costs.

When optimizing printed circuit board (PCB) assembly, several key factors significantly influence both performance and cost efficiency. First, the design complexity plays a crucial role; simpler designs typically lead to reduced assembly time and lower manufacturing costs. Therefore, engineers should prioritize design for manufacturability (DFM) principles, incorporating standard components and minimizing the use of specialized parts. This approach not only streamlines the assembly process but also enhances reliability by ensuring consistent quality across the production line.

Second, selecting the right materials is essential for achieving optimal performance while managing costs. High-quality substrates and soldering techniques can dramatically affect the electrical characteristics and thermal management of the PCB. For instance, using advanced materials with better thermal conductivity can prevent overheating and extend the lifespan of electronic components. Balancing performance enhancements with material costs is vital; engineers must evaluate whether the benefits justify the additional expenses, ensuring long-term viability without compromising on quality.

Lastly, the choice of assembly processes should not be underestimated. Techniques such as surface mount technology (SMT) and selective soldering offer increased efficiency and accuracy. Automating these processes can further reduce labor costs while maintaining high production standards. Adapting assembly methods according to batch sizes and production timelines allows for flexibility, which can lead to overall savings without sacrificing the performance benchmarks set for the PCBs.

This chart illustrates the performance scores and cost per unit associated with key factors influencing printed circuit board assembly. Higher material quality and efficient testing protocols contribute to better performance while maintaining competitive costs.

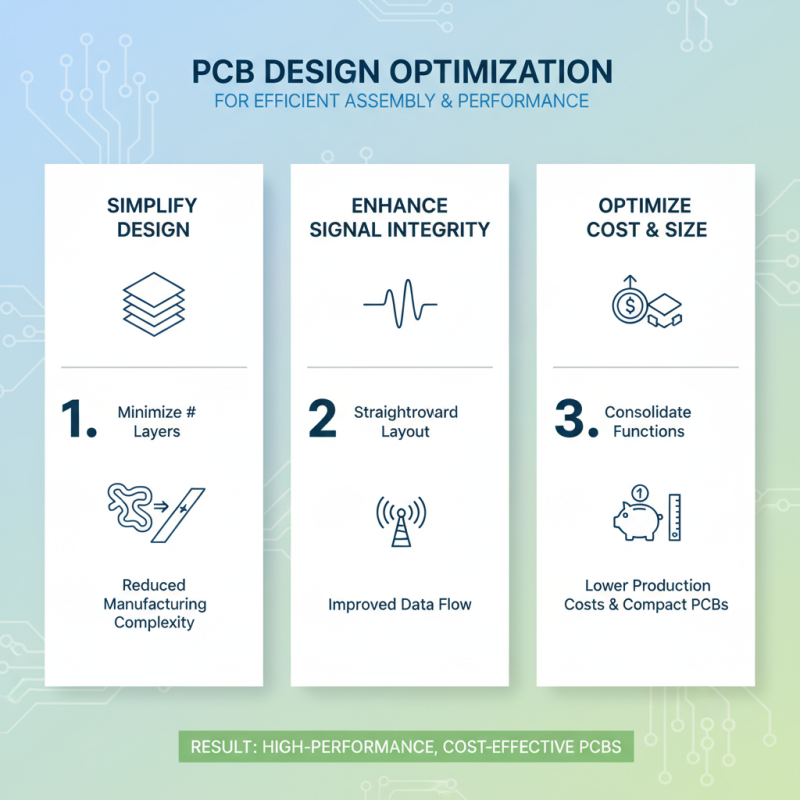

To achieve efficient and high-performance printed circuit board (PCB) assembly, implementing design optimization strategies is essential. One effective approach is to simplify the design by minimizing the number of layers. A straightforward layout reduces manufacturing complexity, enhances signal integrity, and lowers production costs. By strategically placing components and consolidating functions, designers can create more compact and efficient PCBs without compromising performance.

Additionally, choosing the right materials plays a critical role in optimizing PCB assembly. High-quality substrates and solder mask materials can substantially improve reliability and endurance under various conditions. Moreover, designers should consider utilizing surface-mount technology (SMT) instead of through-hole components where possible. SMT offers benefits such as reduced space requirements and improved electrical performance. By incorporating these design considerations, engineers can not only enhance the performance of PCBs but also achieve significant cost savings during the manufacturing process.

Selecting the right materials is crucial for enhancing circuit efficiency in printed circuit board (PCB) assembly. The fundamental properties of materials can significantly influence the thermal and electrical performance of the circuit. For instance, using high-quality copper for traces can minimize resistive losses, thereby improving overall conductivity. Additionally, considering dielectric materials with low loss tangents aids in maintaining signal integrity, especially in high-frequency applications. The choice between various substrate materials, such as FR-4 or newer alternatives, can also play a pivotal role in optimizing thermal management and reducing parasitic effects.

Furthermore, attention to material thickness and surface finishes can contribute to long-term reliability and performance consistency. Thicker copper layers can provide better heat dissipation and allow for higher current-carrying capacity, essential for power-intensive applications. Similarly, selecting the right surface finish can prevent oxidation and enhance solderability, ensuring a strong connection that supports the longevity of the circuit. By carefully assessing these material choices, manufacturers can achieve a balance between performance and cost-efficiency, paving the way for more reliable and competitive products in the market.

The integration of technology and automation in the printed circuit board (PCB) production processes is crucial for enhancing both performance and cost-efficiency. Automation tools streamline various stages of PCB assembly, such as soldering, placement, and inspection, minimizing human error and increasing throughput. Robotics and advanced machinery can handle intricate tasks with precision, significantly reducing the time required for assembly. Utilizing automation software allows manufacturers to plan and optimize production schedules dynamically, leading to more efficient resource allocation and reduced operational costs.

Moreover, leveraging data analytics and real-time monitoring systems can provide valuable insights into the performance of the assembly line. By analyzing production data, manufacturers can identify bottlenecks and areas for improvement, allowing for timely adjustments and better overall workflow management. Smart technologies, including artificial intelligence and machine learning, can predict potential issues and enhance quality control processes. This results in not only improved yield rates but also a reduction in material waste, contributing to a more sustainable production model while maintaining cost-effectiveness across the board.