30+ Years of Experience in PCB Design and Manufacturing

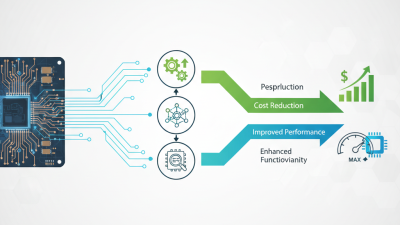

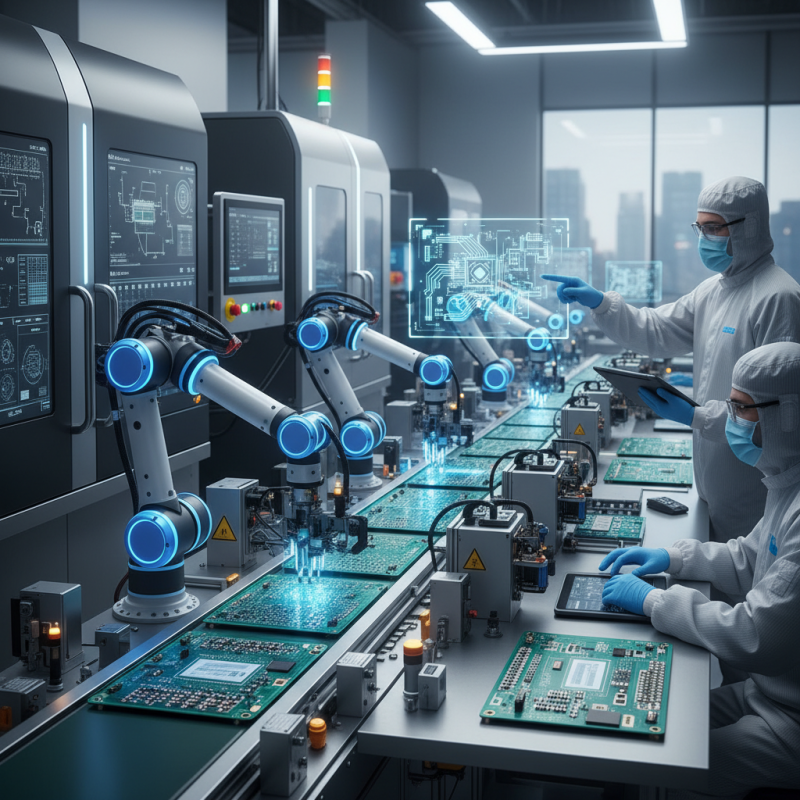

In today's competitive electronics market, optimizing PCB production is critical for manufacturers aiming for both cost efficiency and enhanced quality. According to a recent report by IPC, the global PCB market is anticipated to reach approximately $77 billion by 2025, underscoring the pressing need for manufacturers to refine their production processes. As the demand for smaller, denser, and more reliable circuits increases, leveraging advanced manufacturing technologies and streamlined operational practices has become essential.

Cost efficiency in PCB production not only hinges on material selection and labor costs but also on the implementation of best practices in design and manufacturing processes. A study by the Research Institute of PCB Technology indicates that optimizing production lines can reduce costs by up to 30%, while simultaneously improving yield rates and product quality. As such, manufacturers must prioritize a comprehensive strategy that aligns their production capabilities with industry standards, enabling them to achieve a competitive edge while meeting the evolving demands of consumers.

Moreover, enhancing quality in PCB production requires an unwavering focus on innovation and continuous improvement. Industry leaders recognize that investing in state-of-the-art technology, automation, and skilled workforce development is indispensable for realizing these objectives. By balancing cost efficiency with quality enhancement, manufacturers can not only boost their profit margins but also ensure customer satisfaction, thereby establishing long-term success in the ever-evolving PCB industry.

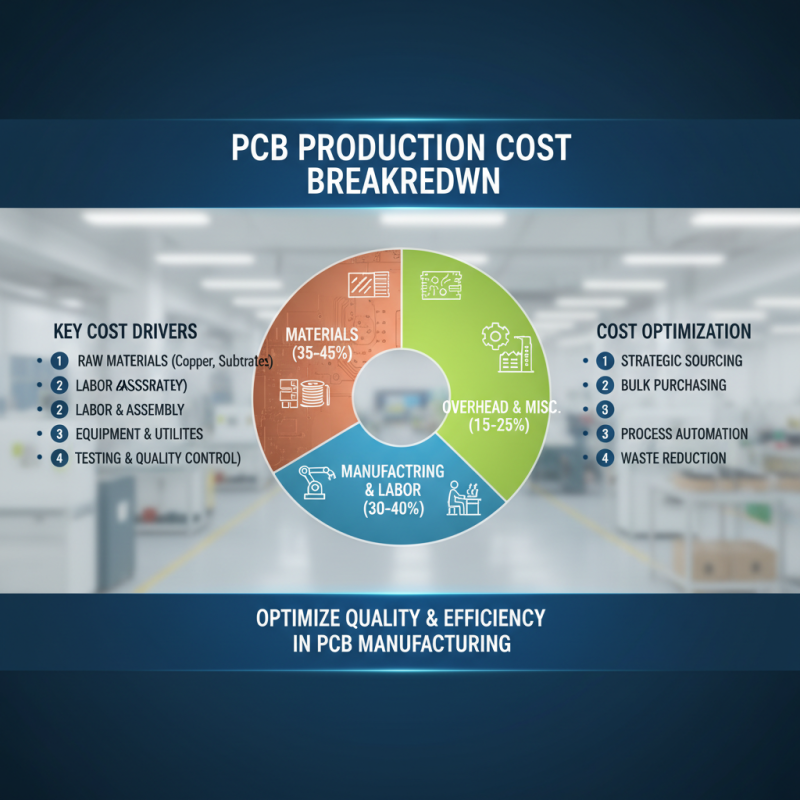

In the realm of printed circuit board (PCB) production, understanding the cost structure is essential for optimizing both cost efficiency and quality. According to industry reports, material costs account for approximately 35% to 45% of the total production expenses. This includes raw materials such as copper, substrates, and laminates. By strategically sourcing high-quality materials at competitive prices and leveraging bulk purchasing agreements, manufacturers can significantly reduce costs while maintaining the integrity of the final product.

Labor and operational costs also play a vital role in the PCB production cost structure, typically representing around 25% to 30% of the total expenses. Streamlining manufacturing processes through automation and implementing lean manufacturing principles can lead to substantial labor savings. Reports indicate that companies adopting automation have observed a reduction in labor costs by as much as 20% while simultaneously increasing production capacity and efficiency. Furthermore, investing in employee training programs enhances skill levels, resulting in fewer errors and high-quality output that ultimately drives down rework costs.

Lastly, overhead costs, including utilities, rent, and maintenance, can make up about 10% to 15% of total PCB production costs. By optimizing facility management and utilizing energy-efficient machinery, manufacturers can reduce these costs. For example, adopting energy management systems can lead to a reduction in energy consumption by 10% to 20%, directly impacting the overall production expenses. By focusing on these key factors within the cost structure, PCB manufacturers can enhance their cost efficiency and improve product quality in an increasingly competitive market.

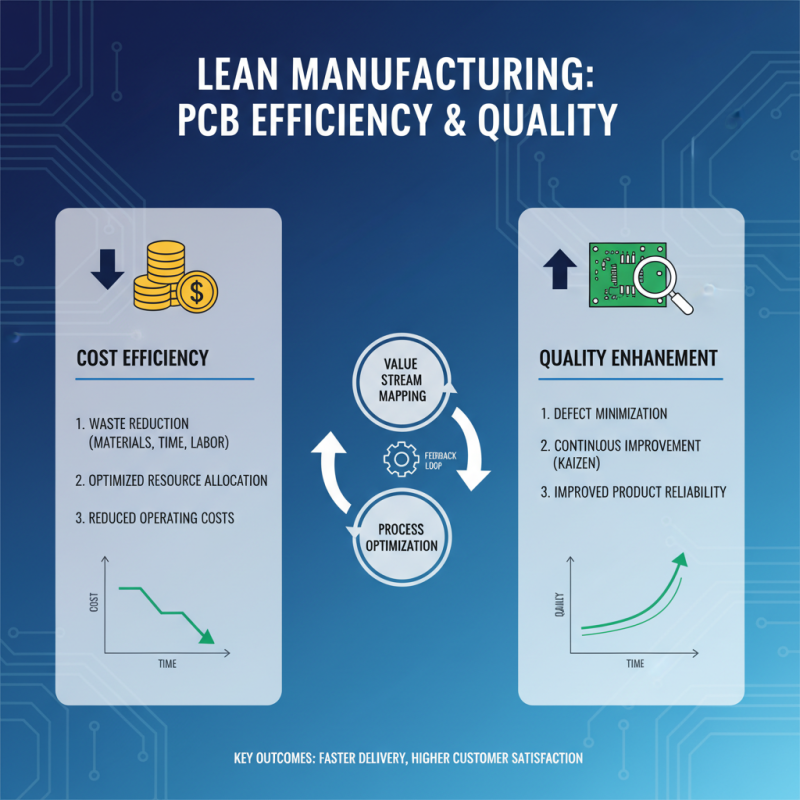

Implementing Lean Manufacturing Principles can significantly enhance cost efficiency and quality in PCB production. Lean manufacturing focuses on minimizing waste without sacrificing productivity, which is crucial in the highly competitive landscape of PCB manufacturing. By applying principles such as value stream mapping and continuous improvement, manufacturers can identify areas where resources are being wasted, whether it be in materials, time, or labor. This systematic analysis not only streamlines processes but also helps in reallocating resources more effectively to areas that add value to the product.

Moreover, fostering a culture of continuous improvement within the workforce encourages employees to contribute to efficiency initiatives. Training teams to identify inefficiencies and suggest improvements cultivates an environment where innovation thrives. Emphasizing cross-functional teamwork can break down silos, leading to better communication and faster problem-solving. Additionally, employing techniques such as Just-In-Time (JIT) manufacturing ensures that materials are available as needed, reducing excess inventory and related costs. By centering operations around lean principles, PCB producers can maintain high-quality standards while significantly reducing production costs and delivery times.

The pathway to optimizing PCB production hinges on integrating advanced technology that not only enhances efficiency but also elevates the quality of the final product. By leveraging cutting-edge methods such as automated inspection systems and sophisticated software for design and simulation, manufacturers can significantly reduce errors and accelerate production timelines. These technologies enable teams to identify potential issues early in the design phase, ensuring a high level of precision in manufacturing processes.

Tips: Incorporate machine learning algorithms in the inspection process to adapt to common defects, improving accuracy over time and reducing the need for repeated manual checks. Additionally, consider implementing smart manufacturing tools that utilize real-time data analytics for ongoing quality monitoring during production.

Investing in automated assembly lines is another strategy that can drastically improve both cost efficiency and product quality. Automation not only speeds up the assembly process but also minimizes human error, which can lead to variances in quality. By adopting robotic systems and automated soldering techniques, companies can achieve a level of consistency and reliability that meets the highest industry standards.

Tips: Regularly update the automation technology to keep pace with innovations in the field. This ensures that your production line remains competitive and that you can implement the latest efficiency improvements as they become available.

Effective material management is crucial for enhancing the cost efficiency of PCB production while simultaneously improving overall quality. By implementing strategic sourcing and optimizing inventory levels, manufacturers can significantly minimize waste. This involves analyzing the full lifecycle of materials used in PCB production, from procurement to disposal. By selecting the right materials that align with project requirements and production capabilities, manufacturers can not only reduce excess materials but also lower costs associated with storing and handling them.

Moreover, adopting Just-in-Time (JIT) inventory systems helps in maintaining optimal stock levels, which prevents overproduction and reduces material wastage. This approach ensures that components are available when needed without incurring additional costs for storage. Integrating advanced software solutions to track and manage inventory can further enhance visibility and streamline processes. This not only facilitates better decision-making regarding material usage but also aids in identifying areas where cost reductions can be made, promoting a continuous cycle of improvement in efficiency and quality.

Monitoring performance metrics is essential for assessing production efficiency and quality in PCB manufacturing. Key indicators such as cycle time, defect rates, and yield ratios provide insight into operational processes and help identify areas for improvement. By regularly analyzing these metrics, manufacturers can pinpoint inefficiencies, adjust workflows, and ultimately enhance product quality. For instance, tracking defect rates can reveal specific stages in production where issues frequently arise, allowing focused interventions to reduce errors.

Tip: Establish a real-time monitoring system that integrates with your production line. By implementing robust software tools, you can collect data continuously, enabling quicker response times to emerging issues. This proactive approach not only mitigates costly delays but also fosters a culture of continuous improvement.

Moreover, leveraging data analysis can significantly bolster decision-making capabilities. By compiling historical performance metrics, manufacturers can forecast trends, set realistic targets, and allocate resources more effectively. Regular reviews of these analytics help maintain a balance between cost-efficiency and quality, ensuring that production goals align with industry standards.

Tip: Conduct periodic audits of your performance metrics to ensure that your quality control processes remain effective. Engaging your team in these evaluations can also build a shared sense of responsibility toward maintaining high standards across all production phases.