30+ Years of Experience in PCB Design and Manufacturing

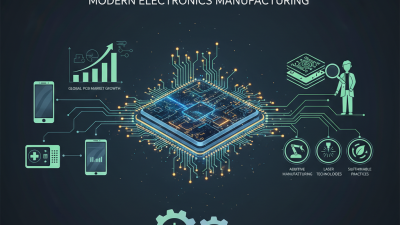

In the rapidly evolving electronics industry, mastering PCB fabrication is crucial. According to the IPC, the global PCB market reached $75 billion in 2022 and is projected to grow. Efficient fabrication techniques influence the performance and reliability of circuit boards. Companies cannot afford to overlook the quality in production processes.

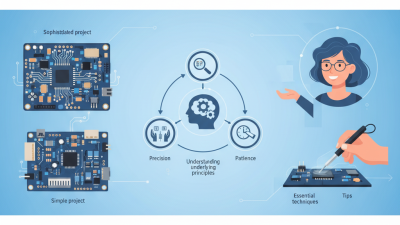

The complexity of PCB fabrication requires a deep understanding of materials and techniques. Inadequate knowledge can lead to increased costs and defects. For instance, a study by the IEEE stated that improper layer alignment can decrease a board's functionality by 30%. Each stage in fabrication must be handled with precision to avoid such challenges.

As technology advances, designers must adapt to new techniques. Emerging trends like flexible PCBs demand innovative approaches. However, these advancements introduce new risks. The balance between innovation and quality assurance in PCB fabrication is delicate. Embracing this challenge can lead to significant advantages in the competitive landscape of electronics.

When diving into PCB fabrication, having the right tools and equipment is crucial. A study highlighted that improper tools can lead to a refuse rate of up to 30% in manufacturing circuits. Essential equipment includes a reliable CNC milling machine, which allows for precision drilling and cutting of circuit board layers. The precision of these machines directly affects the overall quality of the final product.

Another must-have is a PCB etching tank. This piece of equipment is vital for developing the circuitry design. An improperly calibrated tank can result in uneven etching. This not only compromises the circuit’s functionality but also impacts the soldering process later on. Keeping your tools well-maintained is necessary to avoid these issues.

Tip: Invest in quality tools. They are worth the initial expense. Additionally, consider setting up a regular maintenance schedule for your equipment.

Having a laminator is also important. It helps in bonding layers effectively. However, watch out for temperature fluctuations during the lamination process. These can warp your boards, leading to major misalignments.

Tip: Always check the temperature settings before lamination. It can save time and materials.

By focusing on the right tools and their maintenance, you can significantly improve your PCB fabrication quality. Each piece plays a vital role in the creation of quality circuit boards.

Quality circuit boards hinge on understanding key PCB design principles. These principles guide designers in creating efficient layouts. For instance, a report by IPC indicates that improper design accounts for over 30% of PCB failures. This statistic underscores the importance of adhering to established guidelines.

A well-designed PCB layout minimizes interference and enhances performance. It’s crucial to consider trace width, spacing, and layer stack-up. According to a survey by Mentor Graphics, 52% of engineers struggle with signal integrity issues due to inadequate design practices. Ensuring the right trace width based on current requirements can significantly reduce this risk.

The selection of materials also plays a vital role. Subpar material choices can lead to reliability issues. Designers must balance cost and performance. A study from the IEEE indicates that 60% of design alterations stem from material failures. This data highlights a common area where mistakes happen. Attention to detail can help avoid costly redesigns.

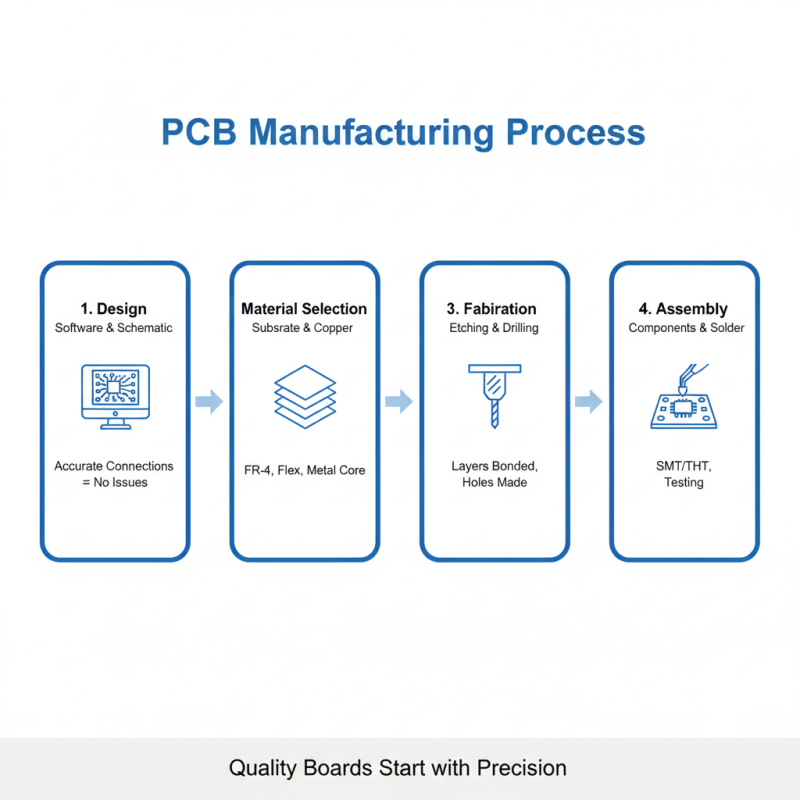

When it comes to PCB manufacturing techniques, understanding the process is crucial for creating quality circuit boards. Start with design. Use software to create your schematic diagrams. Ensure all connections are accurate. Any mistake here could lead to functional issues later.

Next, move to the material selection phase. Choose the right substrate material that meets your design's requirements. Common materials include FR-4 and polyimide. Pay attention to thickness and thermal properties. These factors greatly affect durability and performance.

**Tips:** Check for design rule violations during software checks. A small mistake can destroy the entire board.

Once materials are ready, proceed to the photolithography stage. Create a photoresist layer on your substrate. This layer needs to be precisely exposed to light for proper patterning. Misalignment during this step can ruin the circuit design.

**Tips:** Regularly calibrate your equipment to avoid inaccuracies. This process demands precision.

After etching, inspect the board. Look for any defects or inconsistencies in the traces. These flaws can lead to signal loss or failures. Remember, quality checks are essential. The final assembly also requires careful attention to soldering and component placement. Each step impacts the end product.

In the world of PCB fabrication, common defects can significantly impact the quality of circuit boards. Misalignment during the layering process can lead to faulty connections. Poor etching can cause incomplete circuits, leading to device failure. These problems need attention, as they directly affect performance.

Tips to avoid defects include inspecting alignment before pressing layers together. Always check for proper exposure times during the etching process. Use high-quality materials; subpar substrates can result in defects. It's crucial to maintain a clean workspace. Dust or residues on surfaces can cause shorts or open circuits.

PCB fabrication requires precision. However, mistakes can happen. An unexpected miscalculation in the design phase could lead to costly errors later. Learning from defects is essential. Each issue provides insight into the fabrication process. This reflection helps improve future designs and ultimately leads to better circuit board quality.

| Defect Type | Description | Causes | Prevention Techniques |

|---|---|---|---|

| Open Circuit | Missing electric connections | Poor etching, design errors | Thorough design checks, optimized etching process |

| Short Circuit | Unintended electrical connections | Excessive copper or contaminants | Use of solder masks, careful cleaning |

| Poor Solder Joint | Weak electrical connections | Inadequate solder, contamination | Proper solder application, thorough cleaning |

| Copper Voids | Holes in copper plating | Bubbles during plating | Controlled plating conditions, degassing |

Testing and quality control are essential in PCB fabrication. Each circuit board must meet specific standards to ensure reliability. One common method is visual inspection. It often reveals visible defects, such as scratches or misaligned components. However, visual checks can miss subtle issues. Relying solely on the human eye may not be sufficient.

Another approach is electrical testing. This method checks the functionality of the circuit. A flying probe test is often used for prototypes. It connects to various points on the board, ensuring electrical paths are correct. Yet, this could overlook intermittent faults that only occur under certain conditions. Every PCB should also undergo thermal cycling tests. This simulates extreme temperature variations, revealing potential weaknesses in materials.

Documentation is crucial throughout the process. Keeping thorough records helps track defects and testing outcomes. However, it can be easy to overlook this step in a fast-paced environment. Companies may rush through tests to meet deadlines. This neglect can result in costly mistakes. Striving for improvement in testing methods can greatly enhance the quality of circuit boards.