30+ Years of Experience in PCB Design and Manufacturing

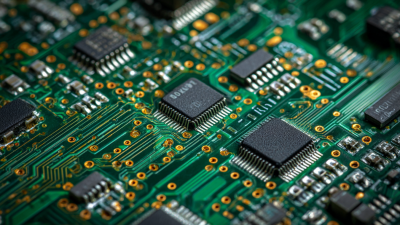

PCB manufacturing is a critical process in the electronics industry, playing a pivotal role in the functionality of modern devices. As technology continues to advance, the demand for high-quality printed circuit boards (PCBs) has surged, emphasizing the need for manufacturers to adopt best practices in their production processes. Whether you are a seasoned professional or new to the field, understanding the essentials of PCB manufacturing can greatly enhance your capabilities and efficiency.

In this guide, we present ten essential tips that are crucial for successful PCB manufacturing. From selecting the right materials to implementing stringent quality control measures, these insights aim to help manufacturers optimize their operations and ensure product reliability. By focusing on these key areas, businesses can reduce costs, minimize errors, and improve overall production timelines. Embracing these best practices will not only lead to higher quality PCBs but also foster customer satisfaction and drive long-term success in the competitive electronics landscape.

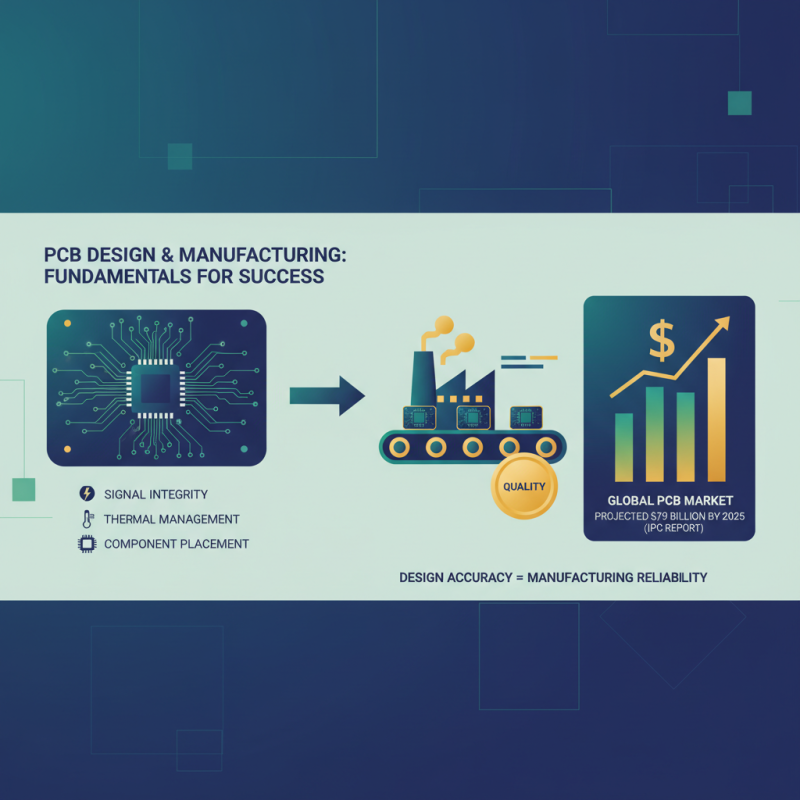

Understanding the fundamentals of PCB design and manufacturing is critical for achieving successful outcomes in the electronics industry. According to a report by IPC, the global PCB market is projected to reach $79 billion by 2025, highlighting the growing demand for effective PCB solutions. A key aspect of ensuring quality in manufacturing starts with design accuracy. Engineers must be well-versed in the principles of signal integrity, thermal management, and component placement to enhance efficiency and reliability in the final product.

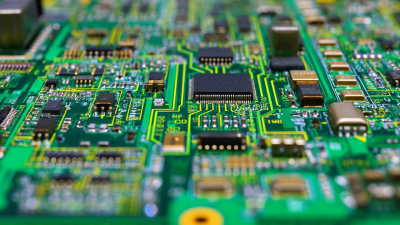

One essential tip for PCB manufacturing is to focus on minimizing the number of layers. A simpler design not only reduces costs but also minimizes the potential for manufacturing errors. According to a study by the IEEE, PCBs with fewer layers tend to yield a higher rate of reliability in performance. Additionally, thorough DFM (Design for Manufacturability) practices should be integrated throughout the design process. This involves creating designs that are easier and more cost-effective to produce without sacrificing quality.

Another critical consideration is the choice of materials. High-quality dielectric materials can significantly impact signal performance and durability. Research from the Electronics Manufacturing Services (EMS) industry indicates a correlation between material selection and the longevity of PCB applications. By ensuring proper material choices, designers can improve the overall functionality of their boards and reduce production failures. Staying informed about the latest advancements and best practices in PCB design and manufacturing is essential for maintaining a competitive edge in this fast-evolving field.

When embarking on PCB manufacturing, selecting the right materials is crucial for ensuring product reliability and performance. A well-considered choice of materials not only affects the durability of the PCB but also its efficiency and cost-effectiveness. According to a recent industry report by IPC, nearly 30% of PCB failures can be traced back to material defects, highlighting the importance of proper material selection in the manufacturing process.

One essential tip for successful PCB manufacturing is to assess the specific demands of your project. High-frequency boards may require materials that handle higher temperatures and offer better dielectric properties, such as Rogers or Teflon-based substrates. In contrast, standard FR-4 materials work well for basic applications but might not suffice for high-performance devices. Selecting a material that aligns with the electrical requirements can significantly enhance the PCB's performance and longevity.

Another critical aspect is the thermal management of the PCB. Properly chosen thermal materials can dissipate heat efficiently, preventing potential failures. For instance, using materials with lower thermal resistance can improve heat distribution and support higher power applications. The IPC's report also indicates that improper thermal management is a leading cause of electronic component inefficiencies, contributing to a notable decrease in overall device lifespan. By focusing on the right combination of materials for thermal and electrical properties, manufacturers can elevate their PCB projects to new heights.

In the realm of PCB manufacturing, precision in fabrication processes is paramount. The integrity of the final product hinges on meticulous attention to detail during each stage of production. According to a report by the IPC (Institute of Printed Circuits), nearly 50% of failures in PCB assemblies are attributed to inadequate manufacturing processes. This statistic illustrates the critical need for manufacturers to adopt stringent quality controls and precise techniques to avoid costly rework and ensure reliability.

Accurate fabrication methods encompass a variety of processes, including etching, drilling, and layering. The advancements in automated manufacturing systems have improved the consistency and accuracy of these processes. In fact, a study published by the IEEE highlighted that companies implementing AI-driven quality assurance systems in their PCB production saw a reduction in defects by up to 30%. By investing in precise fabrication processes, manufacturers not only enhance product quality but also significantly boost production efficiency, addressing challenges in a rapidly evolving technological landscape.

Ultimately, the emphasis on precise fabrication in PCB production is not merely a matter of operational efficiency; it directly impacts the performance and longevity of electronic devices. As the demand for more complex and reliable PCBs continues to rise, manufacturers must prioritize precision in their fabrication processes to stay competitive in the industry.

Testing is a crucial step in the PCB manufacturing process, ensuring that each board functions as intended and meets quality standards. Various testing methods can be employed to evaluate the performance and reliability of PCBs. One common approach is Automated Optical Inspection (AOI), which uses high-resolution cameras to visually inspect the solder joints and PCB layout for any defects or inconsistencies. This method is efficient and can detect issues such as missing components, improper soldering, or alignment errors early in the production process.

Another essential testing method is Functional Testing, which involves powering the PCB and verifying that it performs its intended functions. This type of testing ranges from simple checks of power supply and signal integrity to more complex assessments of full operational capabilities under various conditions. Additionally, In-Circuit Testing (ICT) can be employed to assess individual circuit elements by measuring resistances, capacitances, and other electrical properties directly on the assembled board. Together, these testing methods play a vital role in preventing failures and ensuring high-quality performance in the final product, ultimately saving time and costs associated with post-production fixes.

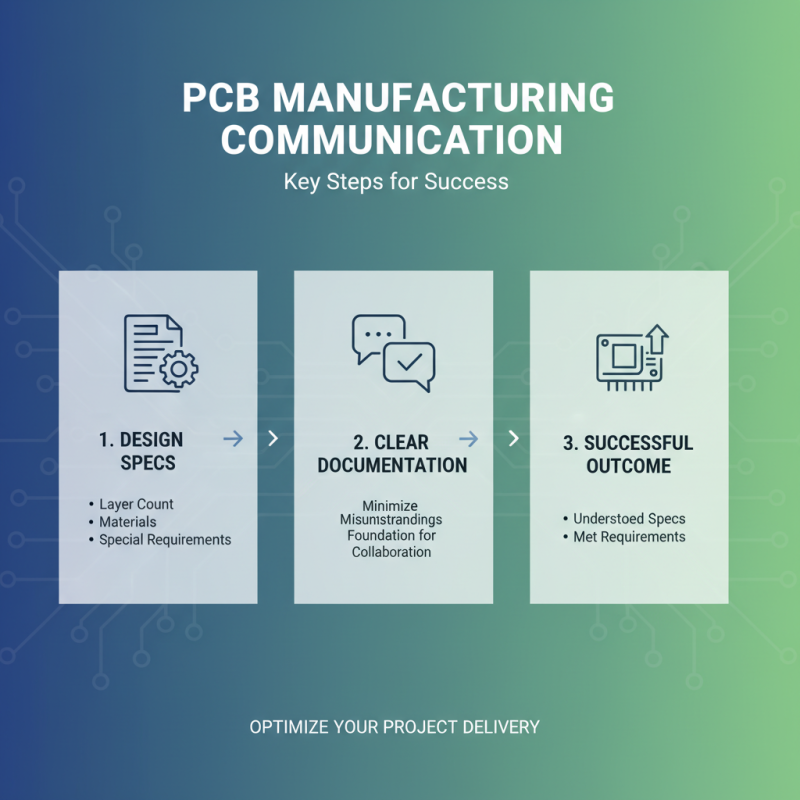

Effective communication with PCB manufacturers is crucial for achieving successful outcomes in your project. To ensure that your specifications are understood and met, it's essential to provide clear and detailed documentation. Start with a comprehensive design specification that includes all necessary details such as layer counts, materials, and special requirements. This helps to minimize misinterpretations and sets a clear foundation for your collaboration.

Another tip is to maintain regular communication throughout the manufacturing process. Schedule checkpoints to discuss progress and address any challenges that may arise. This proactive approach helps to ensure that any potential issues are dealt with promptly, reducing delays and maintaining the project timeline. Regular updates can foster a strong partnership and enhance overall efficiency.

Finally, be open to feedback from your manufacturer. They may offer valuable insights based on their experience that could enhance the quality of your PCB. Consider their recommendations seriously, as their expertise can contribute to a more successful and cost-effective manufacturing process. By prioritizing effective communication, you can create a fruitful collaboration that leads to high-quality PCB outcomes.