30+ Years of Experience in PCB Design and Manufacturing

In the world of electronics, the design of a printed circuit board (PCB) is crucial for ensuring the functionality and reliability of devices. As noted by Dr. Emily Chen, a leading expert in PCB design, "An effective printed circuit board is not just a blueprint; it’s the foundation for innovation and performance in electronic devices." This highlights the importance of adopting best practices in PCB design to enhance both efficiency and manufacturability.

Designing an effective printed circuit board requires meticulous attention to detail and a sound understanding of the underlying principles of electronics. From layout considerations to material choices, every decision impacts the final product's performance and longevity. By following essential guidelines, engineers can mitigate issues such as signal integrity, thermal management, and electromagnet interference, creating PCB designs that meet industry standards and customer expectations.

As the demand for more compact and powerful electronic devices continues to rise, the need for sophisticated PCB design becomes ever more critical. With the right strategies and awareness of common pitfalls, designers can create printed circuit boards that not only fulfill technical requirements but also contribute to the overall success of innovative electronic solutions.

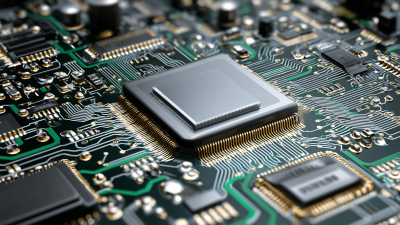

Understanding the basics of printed circuit board (PCB) design is crucial for anyone involved in electronics. A PCB serves as a backbone for electronic components, providing both physical support and electrical connections. To design an effective PCB, it's essential to grasp fundamental concepts such as the layout, routing, and component placement. Each element plays a vital role in ensuring that the board functions correctly and efficiently.

When starting a PCB design, one must consider the principles of signal integrity and power distribution. Proper routing of traces minimizes interference and accommodates the necessary current levels. Additionally, effective placement of components reduces the chances of overheating and ensures that signals travel the shortest paths possible. Understanding these basics not only enhances performance but also simplifies troubleshooting and future modifications. As you embark on your PCB design journey, keeping these core principles in mind will lead to greater success and reliability in your electronic projects.

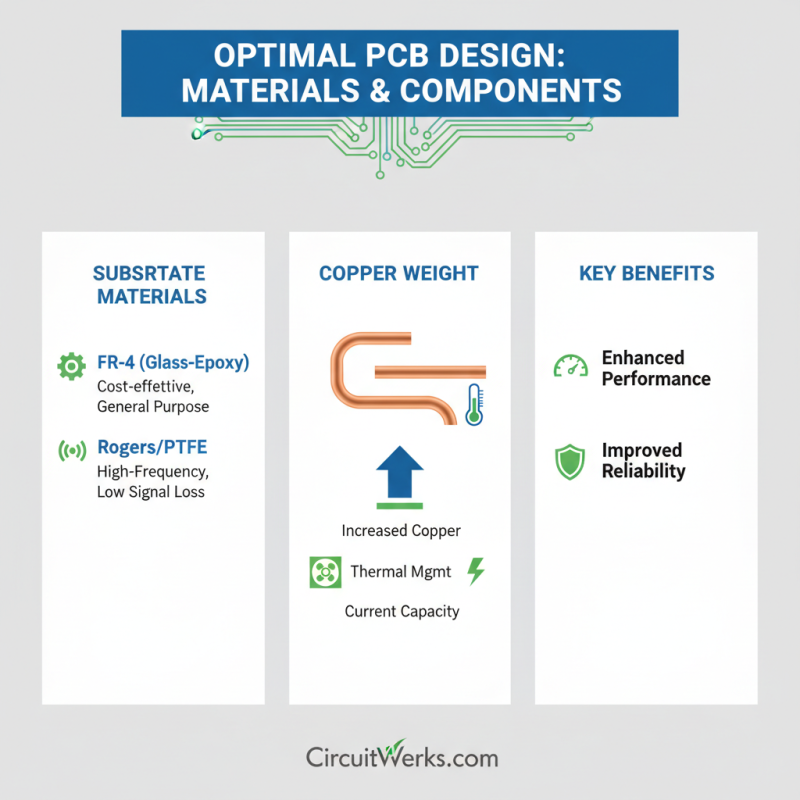

When designing effective printed circuit boards (PCBs), selecting the right materials and components is crucial for ensuring optimal performance and reliability. The substrate material is one of the foundational elements in PCB design. Common choices include FR-4, a glass-reinforced epoxy laminate, which offers a good balance between cost, performance, and ease of manufacturing. For high-frequency applications, using materials like Rogers or PTFE can significantly reduce signal loss and improve overall efficiency. Additionally, copper weight on the PCB should be carefully considered, as it impacts current carrying capacity and thermal management.

Another key aspect of PCB design involves choosing appropriate components. The selection of resistors, capacitors, and integrated circuits affects both the performance and longevity of the PCB. For example, using low ESR capacitors can enhance power supply stability, while choosing components that adhere to the required frequency specifications is vital for maintaining signal integrity. Furthermore, the placement and orientation of these components on the PCB are important to minimize noise coupling and ensure proper thermal dissipation. In sum, prioritizing high-quality materials and strategically selected components will lead to the creation of effective and enduring PCBs.

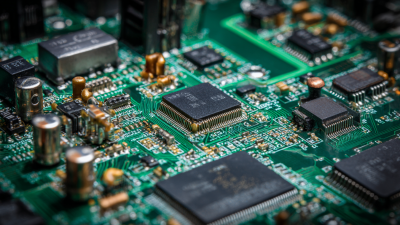

When designing printed circuit boards (PCBs), understanding essential design principles is key to achieving optimal performance and reliability. One fundamental aspect to consider is the placement of components. Strategically positioning components minimizes signal integrity issues and reduces noise interference. It is crucial to group related components together, which helps to shorten the connections between them, thereby reducing potential inductance and capacitance problems. Additionally, maintaining a balanced layout helps distribute power evenly, ensuring that no area of the PCB experiences excessive heat.

Another vital principle involves the effective routing of traces. The width and spacing of traces should be calculated based on the current they will carry, as this affects the overall performance and heat dissipation of the board. Using shorter traces where possible is beneficial as it reduces the chance for signal distortion. Furthermore, implementing ground planes can significantly improve the return path for signals, enhancing electromagnetic compatibility (EMC). Designers should also pay close attention to the vias, as their placement and type can impact both signal integrity and manufacturing costs. By adhering to these principles, PCB designers can create efficient, high-performance boards that meet the demands of modern electronic applications.

Testing and prototyping are vital components in the development of printed circuit boards (PCBs). Before a design can be finalized, it is essential to create prototypes that enable engineers to identify potential flaws and inefficiencies. Prototyping not only allows for practical evaluation of the circuit design but also helps in assessing the mechanical and thermal properties. By simulating real-world conditions, designers can observe how their circuits perform under stress, ensuring that any design errors are addressed early in the process.

Moreover, thorough testing helps validate the functionality of the PCB. This includes electrical testing to verify that signals are transmitted correctly, as well as environmental testing to ensure durability under various conditions. Conducting these tests allows teams to catch issues such as signal integrity problems, power distribution inefficiencies, or thermal management failures. By incorporating rigorous testing and iterative prototyping, designers can enhance the reliability and performance of their circuits, ultimately leading to a more successful final product.

Documenting and managing PCB design files is a crucial aspect of the design process that can significantly impact the efficiency and accuracy of project outcomes. According to a report by IPC, effective documentation practices can reduce design errors by up to 30%, which translates into substantial cost savings and enhanced productivity. A well-organized file management system ensures that all team members can access the latest design revisions, incorporate necessary changes, and collaborate seamlessly. Utilizing standardized naming conventions, version control, and comprehensive design documentation helps to minimize confusion and ensures that critical information is not overlooked.

In addition to establishing a robust file management system, adopting best practices in documenting the design process is essential. This includes detailed records of design decisions, schematic diagrams, and annotations for each project. A study from the Association for Computing Machinery indicates that teams that consistently document their design processes improve their project timelines by approximately 25%. By maintaining clear and thorough documentation, engineers can better trace back decisions and quickly rectify issues, ultimately leading to more reliable and efficient PCB designs.

Emphasizing meticulous documentation not only bolsters the development process but also facilitates easier transitions for future projects and team members.