30+ Years of Experience in PCB Design and Manufacturing

In the competitive world of PCB manufacturing, obtaining an accurate PCB quote is crucial. John Smith, a noted expert in the PCB industry, once stated, “A precise quote is the first step towards project success.” His words emphasize the importance of clarity and detail when seeking quotes.

Navigating the PCB quote process can be challenging. Many factors come into play, including material specifications and design complexity. Often, customers overlook important details. This oversight can lead to unexpected costs down the line. It’s essential to communicate your needs clearly to manufacturers.

Mistakes in the quoting stage can have lasting effects. It can delay projects or increase budgets unexpectedly. Understanding the nuances of the PCB quote process can save considerable time and money. Taking the time to gather the right information is well worth the effort in the long run.

When it comes to PCB manufacturing, understanding the basics is crucial. A well-structured quote helps ensure that you get what you want. You need to know how the manufacturing process affects the cost. Several factors come into play. Materials, layer count, and special features all influence pricing.

Many overlook the importance of design details. Complex designs can lead to higher costs. Having clear specifications can prevent unexpected charges. Always double-check your files. Mistakes can be costly and delay the project timeline. Aim to communicate openly with the manufacturer. Ask questions if anything is unclear. This transparency can lead to better quotes and products.

Neglecting these aspects may result in compromises. It’s important to reflect on your design needs. Overlooking simple requirements could lead to confusion. Providing precise information is a must. Being vague may lead to misunderstandings. Focus on clarity to avoid unexpected hurdles. A little extra effort upfront can save time and money later.

| Tip | Description | Considerations | Estimated Impact on Cost |

|---|---|---|---|

| 1. Define Specifications | Clearly define PCB dimensions, layers, and material to avoid miscommunication. | Material choice significantly affects price. | High |

| 2. Quantity | Determine the number of units needed; bulk orders often reduce per-unit costs. | Ordering fewer units can lead to higher costs. | Medium |

| 3. Lead Time | Specify your production timeline; faster lead times can increase costs. | Might require expedited processing fees. | High |

| 4. Design Complexity | More complex designs require more time and resources to manufacture. | Can impact both time and cost. | High |

| 5. Surface Finish | Choose the right finish based on assembly requirements—HASL, ENIG, etc. | Certain finishes can add significant costs. | Medium to High |

| 6. Testing Requirements | Include any testing needed for quality assurance. | More testing increases overall costs. | Medium |

| 7. Shipping Options | Choose a shipping method that aligns with your timeline and budget. | Faster shipping increases costs. | Medium to High |

| 8. PCB Thickness | Specify the PCB thickness as it affects durability and cost. | Thicker boards can cost more. | Medium |

| 9. Design for Manufacturability (DFM) | Ensure designs are optimized for manufacturing to avoid costly modifications. | Inefficient designs add to costs. | High |

| 10. Compare Multiple Quotes | Obtain and compare quotes from several manufacturers. | Ensure you analyze what is included in each quote. | Variable |

When seeking an accurate PCB quote, several key factors impact pricing. Material type plays a crucial role. Different materials have varied costs and properties. For instance, FR-4, a common choice, is typically more affordable than specialized substrates. Be aware of how your selection affects the final price.

Another important aspect is the complexity of the design. Designs with intricate specifications require more time and resources. This can increase labor and production costs significantly. Ensure that your specifications are clear. Ambiguities could lead to additional charges.

PCB quantities are vital too. Ordering in bulk often reduces the cost per unit. However, consider your needs carefully. Overestimating requirements may lead to excess inventory and wastage. Always strive for an optimal balance between cost and need. Each detail, from layer count to finish, shapes the final quote. Reflect on these factors to achieve the best result.

This chart illustrates the key factors that influence PCB pricing. Each element shows the percentage impact on overall costs, helping you understand how to optimize your quote.

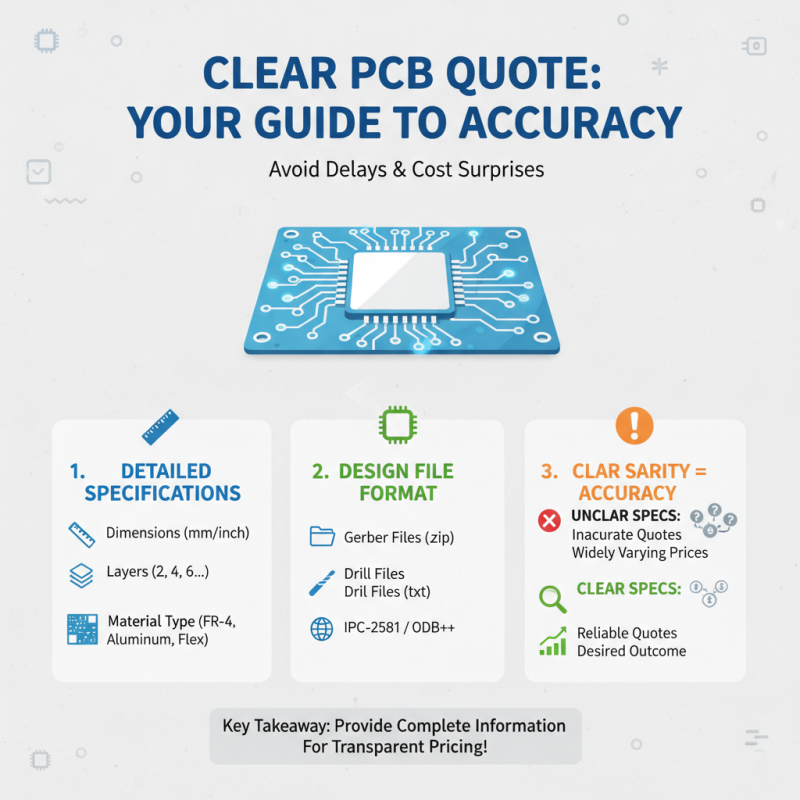

When seeking PCB quotes, clarity is key. Start by providing detailed specifications. Include dimensions, layers, and material types. Mention your design file format. This helps suppliers understand your needs. An unclear specification may lead to inaccurate quotes. You could receive prices that vary widely and may not represent your desired outcome.

Another crucial aspect is the quantity. Specify how many PCBs you require. Smaller orders often result in higher per-unit prices. Consider the trade-off between cost and volume. Shipping preferences are also important. Indicate whether you need fast delivery or if standard shipping works. This information can influence the overall cost significantly.

Lastly, think about any additional services you might need. Assembly, testing, and finishing processes often incur extra costs. Open dialogue with suppliers can clarify these needs. If you forget to mention any details, it could lead to oversights. Reflect on how you present your project to ensure your request is comprehensive. Clear, actionable information leads to more accurate and favorable quotes.

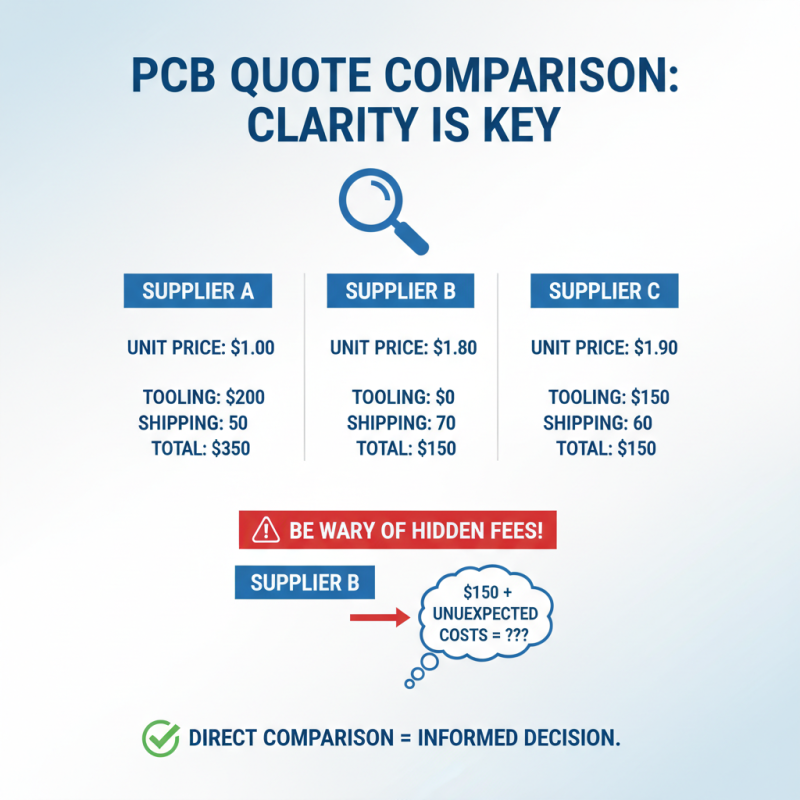

When comparing quotes from different PCB suppliers, clarity is key. Start by gathering several quotes. Each quote should detail the same specifications. This way, you can make direct comparisons. Look for hidden fees that may not be evident at first glance. Sometimes, a cheaper quote can lead to unexpected costs later.

Evaluate the turnaround time as well. Some suppliers may offer lower prices but take longer to deliver. Check the material quality promised in each quote. Not all suppliers use the same grade of material. This can affect both performance and durability. Scrutinize their processes to ensure they meet required standards.

Reassess your own needs during this process. Sometimes, your ideal specifications might not align with industry benchmarks. Are you being too demanding which could inflate costs? Consider the trade-offs between price and quality. Sometimes, investing more up front can save headaches in the long run. Each decision will shape your experience with the PCB design and production process.

Negotiating for the best price on PCB orders is essential. Start by understanding your project's specific needs. Know the specifications, such as size, complexity, and materials. Clear communication helps suppliers understand your requirements. This can lead to better quotes. Sometimes, vague orders result in higher costs. Avoid this by being precise.

Building relationships with multiple suppliers is valuable. Request quotes from various companies and compare them. Look for hidden costs in their offers. Some suppliers may add fees that aren't immediately visible. Transparency is key. If their prices are high, ask for a breakdown. This can reveal areas where adjustments can be made.

Don’t shy away from negotiation. Suppliers often expect some back and forth. If their initial offer is outside your budget, express your concerns. They might provide discounts or alternative solutions. However, be wary of compromises that affect quality. Finding a balance between cost and quality is crucial. Always reflect on the long-term impact of your decisions. Remember, while saving money is important, quality should not be sacrificed.