30+ Years of Experience in PCB Design and Manufacturing

The printed circuit board assembly (PCBA) stands as a cornerstone in the realm of modern electronics, serving as the backbone for an array of devices from smartphones to sophisticated medical equipment. The global market for PCBA is projected to reach approximately $80 billion by 2026, growing at a CAGR of around 5% from 2021, according to a recent industry report by ResearchAndMarkets. This growth is fueled by the rapid advancements in technology and the increasing demand for consumer electronics. Furthermore, the emergence of the Internet of Things (IoT) and smart devices has intensified the need for efficient and reliable PCBA processes, emphasizing their essential role in enhancing performance and functionality. As electronic devices become increasingly complex and miniaturized, understanding the significance of printed circuit board assembly will be crucial for stakeholders aiming to stay competitive in this dynamic environment.

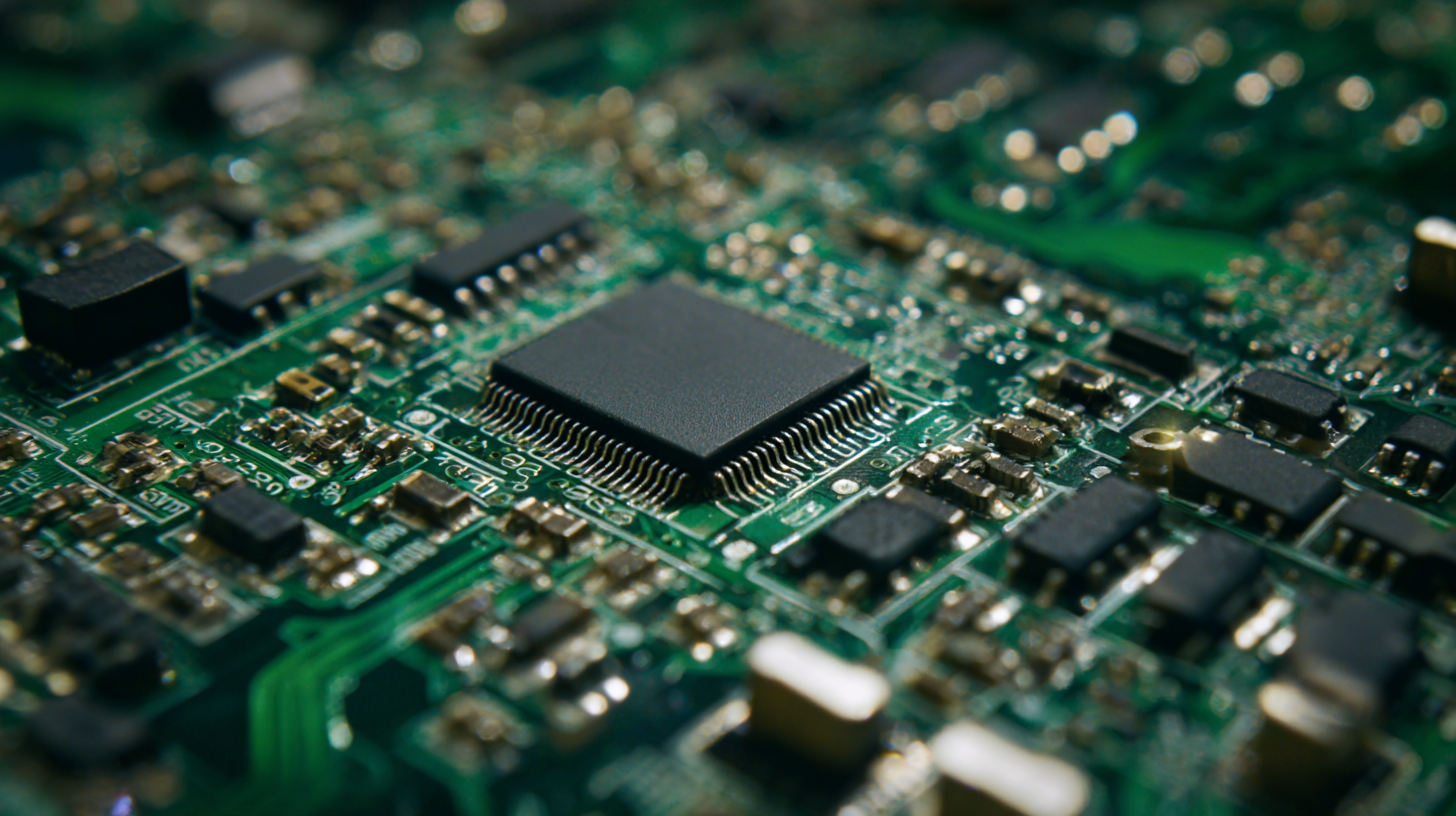

The realm of electronics is ever-evolving, driven by innovation and the quest for efficiency. At the heart of this progression lies Printed Circuit Board (PCB) assembly, a crucial element that fosters technological advancement. By enabling the integration of complex circuits onto compact boards, PCB assembly not only streamlines manufacturing processes but also supports the miniaturization of devices, which is essential in meeting consumer demand for portable and multifunctional electronics.

Moreover, the role of PCB assembly in electronic innovation cannot be overstated. It serves as the backbone for a myriad of applications ranging from smartphones to advanced medical devices. As industries push the boundaries of performance and functionality, high-quality PCB assembly becomes imperative. The ability to incorporate cutting-edge technologies, such as surface mount devices (SMDs) and through-hole components, ensures that new electronics can achieve increased reliability and performance standards, driving the next wave of technological breakthroughs. With such a foundational role, PCB assembly is indeed a critical enabler in the quest for smarter, more efficient electronic solutions.

The printed circuit board (PCB) assembly market is poised for significant growth, with projections suggesting a robust increase by 2025. Several factors are fueling this surge, including the rapid advancement of consumer electronics, the expansion of the Internet of Things (IoT), and the increasing demand for electric vehicles. As these technologies evolve, the need for efficient, reliable, and high-quality PCB assembly becomes paramount. Companies are investing in automation and innovative manufacturing processes to improve their production capabilities and meet the growing consumer demand.

Tip: To stay competitive in the PCB assembly market, businesses should focus on enhancing their supply chain efficiency and embracing sustainable practices. Reducing lead times and sourcing eco-friendly materials can not only lower costs but also appeal to environmentally conscious consumers.

As digital transformation continues to reshape industries, the importance of PCBs in modern electronics cannot be overstated. Companies are actively exploring new materials and designs that simplify assembly processes while improving performance and reliability. This ongoing evolution creates numerous opportunities for growth in the market.

Tip: Regularly attending industry conferences and workshops can provide valuable insights into emerging trends and technologies in PCB assembly. Networking with peers and learning from industry leaders can help businesses adapt and innovate in this dynamic landscape.

High-Density Interconnect (HDI) printed circuit boards (PCBs) have become a cornerstone in modern electronics due to their ability to enhance both performance and functionality. According to a report by IPC, the global HDI PCB market is expected to reach $38 billion by 2024, reflecting a compound annual growth rate (CAGR) of approximately 15%. This surge in demand is primarily driven by the increasing miniaturization of electronic devices, where space constraints necessitate the integration of more components within a limited area. HDI technology, which utilizes finer lines and spaces, allows manufacturers to pack more circuitry onto a smaller board, resulting in improved signal integrity and reduced power consumption.

**Tip:** When designing with HDI technology, consider using laser-drilled micro vias which can significantly enhance routing density and reduce the overall board size, thus optimizing the device's performance.

Moreover, HDI PCBs are pivotal in sectors such as telecommunications, automotive, and medical devices where reliability is paramount. A study from the Research and Markets group highlights that HDI PCBs improve performance metrics by as much as 30% in high-frequency applications, minimizing electromagnetic interference and supporting higher data rates. This is crucial for the development of 5G technology and other advanced communications systems.

**Tip:** Always conduct thorough thermal analysis during the design phase of HDI PCBs to ensure effective heat dissipation, maintaining performance and extending the lifespan of the devices.

In today’s rapidly evolving electronics market, the efficiency of Printed Circuit Board (PCB) assembly plays a pivotal role in enhancing cost-effectiveness. Recent trends indicate that manufacturers are leveraging advanced technologies, such as AI, to optimize PCB production processes. According to a report by the McKinsey Global Institute, automating assembly lines can increase productivity by up to 30% while reducing operational costs significantly.

The financial benefits of efficient PCB assembly are substantial, particularly in the face of changing fiscal policies and supply chain dynamics. As noted in the Union Budget 2025-26, adjustments in customs duties are poised to affect component costs, making it crucial for manufacturers to adopt cost-efficient practices. By streamlining PCB assembly processes, organizations can mitigate these financial pressures and realize savings that can be reinvested into innovation. Reports have shown that companies that embrace efficient PCB production systems can save approximately 15-20% on manufacturing expenses annually, directly impacting their bottom line and competitive positioning.

Moreover, the integration of emerging semiconductor technologies—such as organic and perovskite materials—further enhances the potential for cost savings. These technologies not only improve the performance of the circuits but also reduce material costs, thus providing an additional layer of financial advantage for manufacturers engaged in modern PCB assembly practices.

In the fast-evolving landscape of modern electronics, the printed circuit board (PCB) assembly process plays a pivotal role in ensuring product reliability and performance. Recent industry reports highlight that a staggering 70% of electronic failures can be attributed to PCB assembly issues. This underscores the critical need for stringent quality control mechanisms throughout the assembly processes. Implementing best practices in quality assurance not only mitigates risks associated with defects but also enhances overall operational efficiency.

One key takeaway from recent discussions at major quality-focused conferences is the importance of continuous improvement in quality management systems. For example, the emphasis on integrating advanced monitoring technologies and automated inspection systems within PCB assembly lines can significantly reduce human error and improve defect identification rates by over 50%. Such measures are essential, as they contribute to producing high-quality PCBs that are fundamental to the performance of today’s sophisticated electronic devices. As industries push for higher standards, the integration of rigorous quality controls will remain a vital aspect of PCB assembly, driving innovation and bolstering consumer trust.