30+ Years of Experience in PCB Design and Manufacturing

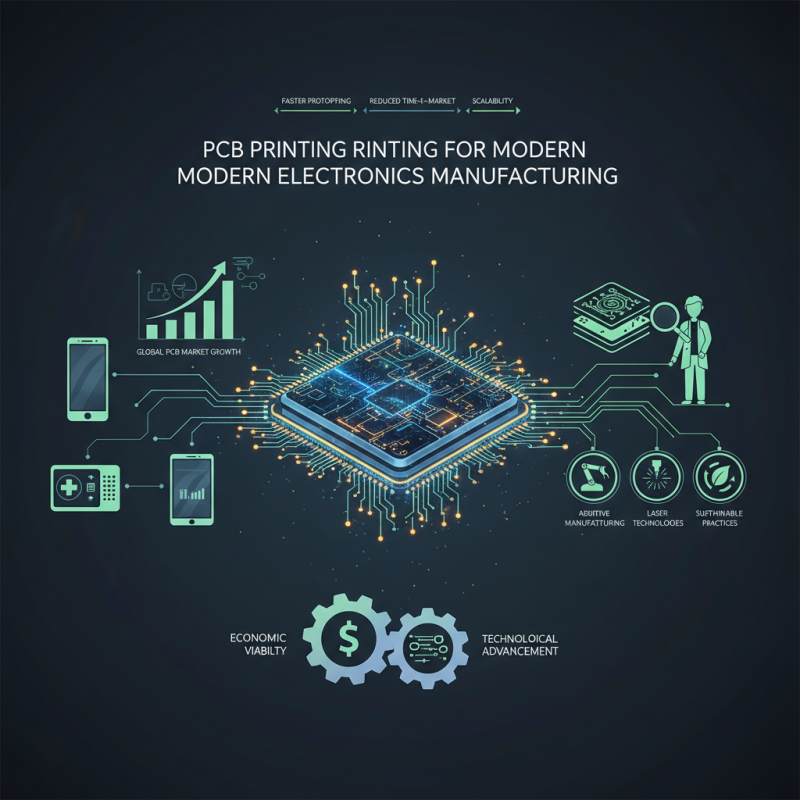

In today's rapidly advancing technological landscape, the significance of PCB printing cannot be overstated. As the backbone of modern electronics, printed circuit boards (PCBs) are essential for the functioning of a myriad of devices, from smartphones to sophisticated medical equipment. According to a report by Research and Markets, the global PCB market is projected to reach USD 83.4 billion by 2026, highlighting the growing demand for efficient and innovative PCB manufacturing techniques, particularly in the domain of PCB printing. This surge in demand necessitates a comprehensive understanding of the advantages and developments within the PCB printing sector.

Industry expert Dr. Amelia Chen, a leading authority on electronic manufacturing, emphasizes the transformative nature of PCB printing, stating, "The evolution of PCB printing technologies is pivotal for enabling the scalability and customization required in today’s electronics. It allows for faster prototyping and reduced time-to-market for new products." As manufacturers strive to meet the ever-increasing consumer expectations for performance and miniaturization, PCB printing stands out as a crucial enabler of innovation, offering both precision and flexibility in design and production.

The advent of advanced techniques such as additive manufacturing and laser technologies within the sphere of PCB printing represents a shift towards more sustainable and efficient practices. With these advancements, manufacturers can not only enhance the quality and reliability of their products but also play a pivotal role in reducing waste and overall production costs. As we delve deeper into the world of PCB printing, it becomes evident that its importance in modern electronics manufacturing is underscored by the interdependence of technology and economic viability.

PCB printing plays a pivotal role in modern electronics manufacturing, serving as the backbone of the electronic devices we rely on daily. The process involves creating intricate circuit designs on a substrate, which allows for the connection of various electronic components. By utilizing advanced printing methods, manufacturers can produce high-density circuits that cater to the increasing demand for more compact and efficient devices. This innovation not only enhances performance but also reduces production costs and turnaround times.

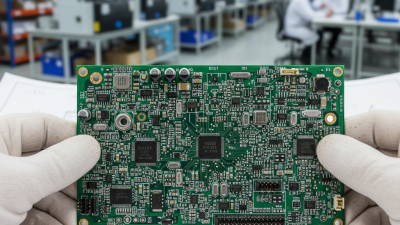

When engaging in PCB printing, it's essential to consider a few tips to ensure optimal results. First, always select high-quality materials for both the substrate and the conductive inks, as this will directly impact the longevity and reliability of the final product. Additionally, investing in precision printing equipment can greatly improve the accuracy and detail of circuit designs, which is crucial for modern electronic applications. Finally, a thorough quality control process should be implemented to catch any defects early, minimizing waste and ensuring the highest possible standards are met.

The importance of PCB printing cannot be overstated; it enables the manufacturing of sophisticated electronic devices with ease and precision. As technology continues to evolve, the techniques employed in PCB printing must also advance, allowing the industry to keep pace with ever-increasing consumer expectations and technological innovations.

PCB printing plays a crucial role in modern electronics manufacturing, offering significant advantages that help streamline production processes. According to a report by IPC, the global PCB market is expected to reach $80 billion by 2027, driven by the increasing demand for electronic devices across various industries. One of the primary benefits of PCB printing is its ability to facilitate rapid prototyping and reduce time-to-market. With advanced PCB printing technologies, manufacturers can create and test circuit designs more swiftly, enabling businesses to stay competitive in a fast-paced environment.

Another key advantage is cost efficiency. Research by ResearchAndMarkets indicates that adopting PCB printing can reduce production costs by up to 30% due to less material waste and lower labor costs. By leveraging automated printing processes, manufacturers can increase production accuracy and consistency while minimizing human error. This efficiency not only helps in optimizing resource management but also allows for the scalable production of complex designs, meeting the rising demands of the market effectively. As the electronics industry continues to evolve, the importance of PCB printing in enhancing production efficiency will become increasingly apparent.

The landscape of PCB printing technologies is rapidly evolving, driven by the increasing demands of modern electronics manufacturing. Innovations such as advanced additive manufacturing and digital printing are emerging trends that allow for faster production times and more complex circuit designs. These technologies enable manufacturers to produce smaller, lighter, and more efficient PCBs, catering to the miniaturization of electronic devices while ensuring high-quality performance.

Tip: To stay ahead in this competitive field, consider investing in training programs for your team to become proficient in the latest PCB printing techniques. This can help enhance productivity and foster innovation within your manufacturing processes.

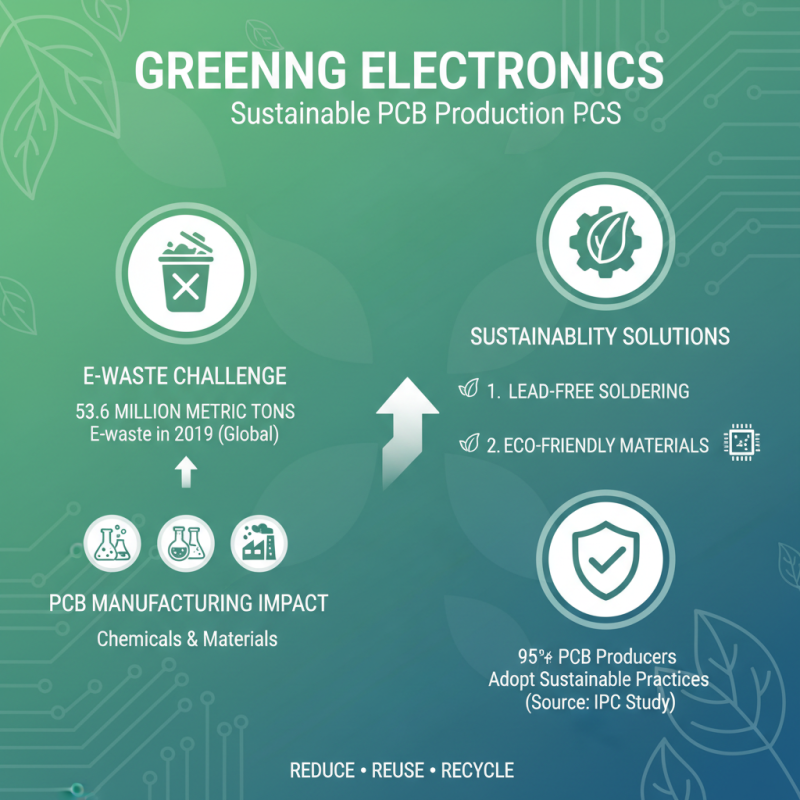

Another significant trend is the rise of eco-friendly materials and processes in PCB printing. Manufacturers are increasingly focusing on sustainability, utilizing materials that reduce environmental impact without compromising performance. This shift not only aligns with global sustainability goals but also appeals to a market that is becoming more environmentally conscious.

Tip: Explore partnerships with suppliers who provide sustainable materials for PCB production to enhance your eco-credentials and attract customers who prioritize environmentally responsible practices.

The market for PCB printing has witnessed exponential growth, acting as a cornerstone for the modern electronics manufacturing industry. As technology advances at an unprecedented pace, the demand for highly efficient, reliable, and compact electronic devices continues to rise. Printed circuit boards (PCBs) are integral components that facilitate these advancements by providing necessary electrical connections within devices. This growth has been boosted by various sectors, including consumer electronics, automotive, and telecommunications, leading to increased investments and innovations in PCB printing technologies.

Economically, the significance of PCB printing cannot be overstated. It not only supports the production of advanced electronics but also generates substantial employment opportunities within the manufacturing sector. The rise in automation and smart manufacturing processes has further streamlined PCB production, enhancing efficiency while reducing costs. This economic impact is compounded by the growing need for sustainable practices, as manufacturers increasingly adopt eco-friendly materials and processes in PCB printing.

Overall, the thriving PCB printing market plays a vital role in both the innovation of electronic products and the economic vitality of the electronics manufacturing landscape.

Sustainability has become a pivotal concern in modern electronics manufacturing, especially in the realm of printed circuit board (PCB) production. The electronic waste generated annually is staggering, with the United Nations reporting that around 53.6 million metric tons of e-waste was produced globally in 2019, a number expected to rise significantly. PCB manufacturing contributes to this issue due to the chemicals and materials used in the printing process. However, advancements in sustainable practices are now reshaping the industry. For instance, implementing lead-free soldering and using environmentally friendly materials can reduce the impact on both health and the environment, as highlighted by a study from the IPC, indicating that over 95% of PCB producers have adopted such practices as part of their environmental responsibility.

Moreover, recycling initiatives for PCBs are gaining traction. According to a report by the International Telecommunication Union (ITU), only 20% of e-waste is recycled, indicating a significant opportunity for growth in sustainable PCB practices. The development of closed-loop recycling systems—where old PCBs are processed to recover valuable materials—can potentially mitigate the environmental footprint of electronics manufacturing. Such systems not only conserve resources but also reduce pollution associated with production processes. As manufacturers recognize the financial and ecological advantages of these sustainable practices, the shift towards responsible PCB manufacturing is not just a trend but a necessity in the modern electronics landscape.