30+ Years of Experience in PCB Design and Manufacturing

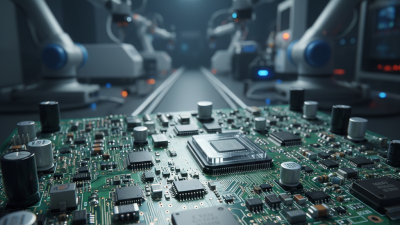

The printed circuit board assembly (PCBA) industry is experiencing rapid growth, driven by the increasing demand for electronic devices. According to a report by ResearchAndMarkets, the global PCBA market is projected to reach $89.3 billion by 2026, expanding at a CAGR of 5.6%. This surge underscores the importance of effective assembly techniques in meeting market demands.

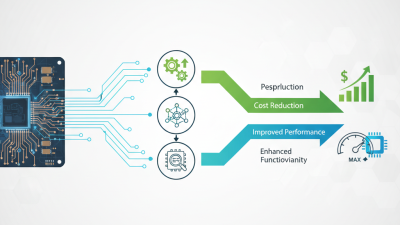

Industry expert Dr. Emily Chen emphasizes the critical nature of efficiency in PCBA. She states, “Streamlining the assembly process can significantly reduce costs and enhance product quality.” This suggests that companies must innovate and adapt their assembly methods to stay competitive. Without continuous improvement, businesses might fall behind.

As technology evolves, traditional methods may become obsolete. Companies need to engage in self-reflection and assess their current techniques. Inadequate training and outdated machinery could hinder progress. Ensuring that your PCBA processes are not only efficient but also effective is vital. Balancing speed and quality is a challenge that needs constant attention in today’s fast-paced environment.

Understanding printed circuit boards (PCBs) is crucial for anyone involved in electronics. PCBs serve as the backbone of most electronic devices. They connect components like resistors, capacitors, and microcontrollers. Each PCB is made of several layers that support and electrically connect these components. According to industry reports, the global PCB market is projected to reach $80 billion by 2026. This highlights their importance in modern technology.

Tips: Always double-check the schematic before assembling. A small error can lead to larger issues. Ensure you have all components ready before starting the soldering process. This prevents delays and maintains productivity.

The assembly process can be challenging. Many beginners struggle with soldering techniques. Poor solder joints can cause functionality issues. In fact, a study found that around 30% of assembly defects relate to soldering mistakes. Using the right solder and tools is essential. Yet, many overlook this. Remembering to clean the PCB before soldering can greatly improve results. It's a simple step, often missed.

Tips: Maintain a tidy workspace. A cluttered area increases the risk of errors. Take regular breaks to avoid fatigue. This keeps your focus sharp, minimizing costly mistakes.

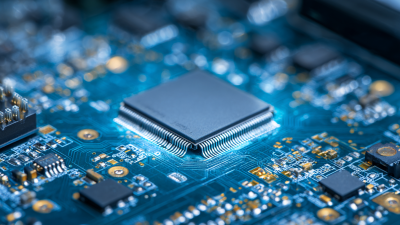

When it comes to assembling printed circuit boards (PCBs), having the right tools and equipment is crucial. For starters, a quality soldering iron is essential. It should heat quickly and provide consistent temperatures. A soldering station can help fine-tune the settings for different components.

Picking the right PCB design software is vital. These tools allow for precise layouts and help avoid costly mistakes. Familiarity with design software can save time and effort during the assembly process. Remember, every click counts, so double-check your designs before proceeding.

Tips: Always test your components before soldering. This step can prevent headaches later. Organize your workspace to avoid confusion. A messy area can lead to errors. All components should be stored in labeled containers for easy access.

An important aspect of assembly is inspection. Use magnification tools to check for solder bridges or misaligned components. Even experienced builders can overlook details, so take your time. Mistakes often occur when rushing, so patience is key.

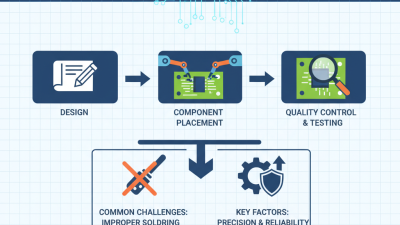

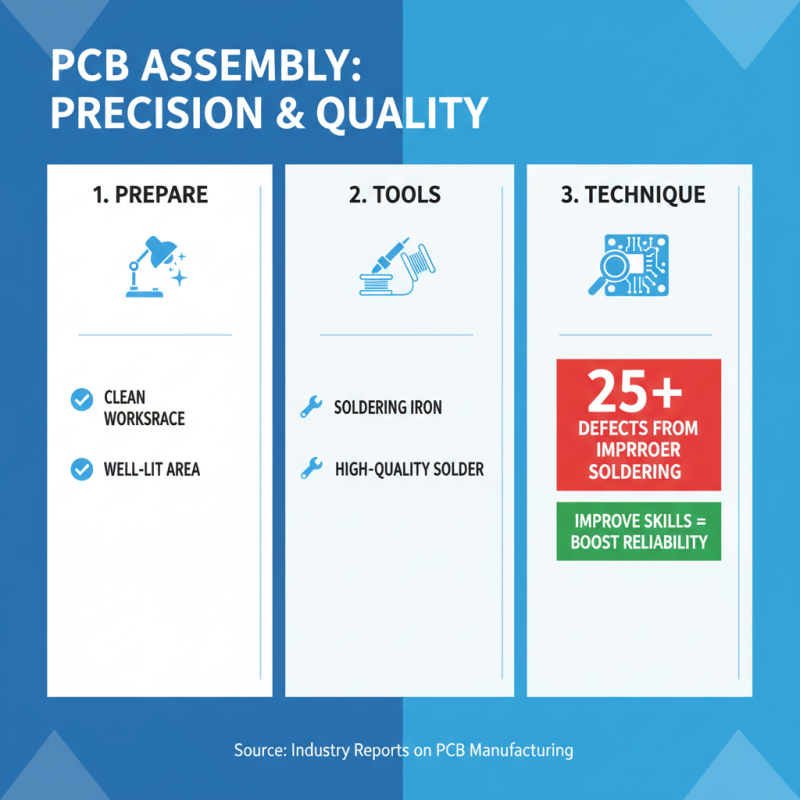

Assembling printed circuit boards (PCBs) requires precision and attention to detail. Start by preparing the workspace to minimize errors. Ensure the area is clean and well-lit. Having the right tools on hand increases efficiency. For example, a reliable soldering iron and high-quality solder are essential. According to industry reports, improper soldering techniques account for over 25% of PCB defects.

Next, it's crucial to follow the design files closely. Double-check the layout against the schematic. Misalignment of components can lead to malfunction. A study by a leading electronics research group revealed that nearly 20% of assembly errors stem from inadequate documentation. Maintaining clear records throughout the assembly process helps identify potential issues.

As you place components, consider thermal management. Overheating can cause damage. Use thermal pads or heatsinks as necessary. Testing intermediate stages can also be beneficial, even if it delays completion. Incorporating these reflections into your workflow helps maintain quality. Continuous evaluation of the assembly process leads to better outcomes over time. Attention to little details makes a significant difference in the final product.

Printed circuit board (PCB) assembly presents various challenges. One common issue is

component misalignment. This often leads to poor connections.

Precision is key in PCB assembly. Even a minor misplacement can provoke functionality issues. Ensuring a correct placement

requires careful handling and testing throughout the process.

Another challenge lies in solder quality. Insufficient solder can cause weak joints.

Excess solder may lead to shorts. Both scenarios result in unreliable performance.

Investing in soldering training and using proper techniques can mitigate these problems. Regular inspections during assembly help

catch defects early.

Moreover, environmental factors can affect assembly quality. Fluctuations in

temperature and humidity may impact materials. These variables can alter the performance of certain components. It's important

to regularly assess the workspace conditions. Continuous learning and adapting strategies

can enhance the overall process.

When assembling printed circuit boards (PCBs), quality assurance is crucial. Each step in the assembly process impacts the final product. To begin with, proper handling of components is essential. Using anti-static mats and wristbands can prevent electrostatic discharge, which may damage sensitive parts. However, not everyone follows these practices consistently. This inconsistency can lead to avoidable defects.

Testing methods are equally important. Functional testing verifies that the assembled PCB performs as intended. Visual inspection helps identify flaws in soldering or component placement. But some teams overlook this step due to time constraints. This oversight can cause significant issues down the line. Using automated optical inspection can catch many mistakes, yet reliance on machines might miss subtle errors.

Designing a thorough quality assurance plan is vital. This includes clear documentation for each assembly phase. Miscommunication can result in errors that affect quality. Regular training sessions for staff can improve awareness. While these strategies are effective, implementing them consistently remains a challenge. It requires ongoing commitment and reflection on existing practices.