30+ Years of Experience in PCB Design and Manufacturing

In the rapidly evolving electronics landscape, selecting the right PCB manufacturing and assembly service is critical for the success of any project. According to a recent report by MarketsandMarkets, the global PCB market is projected to reach $82.83 billion by 2026, growing at a CAGR of 4.6%. This growth underscores the importance of partnering with a reliable service provider capable of meeting increasing demands for quality and efficiency. Industry expert Dr. Emily Tran, a well-respected figure in the PCB sector, emphasizes this point, stating, "The choice of PCB manufacturing and assembly not only impacts production timelines but also the overall reliability and performance of the final product."

Moreover, as technology advances, the complexities involved in PCB design and assembly have increased, necessitating a keen focus on materials, techniques, and industry standards. According to a study by IPC, 60% of businesses reported encountering challenges in their PCB assembly processes which could lead to costly delays and rework. With the right partner, organizations can mitigate these risks and ensure that their PCBs align perfectly with their specifications and performance goals. Understanding the significance of this selection process is essential for businesses aiming to thrive in the competitive electronic market.

The importance of quality in PCB manufacturing and assembly services cannot be overstated, particularly as the electronics industry continues to evolve rapidly. According to a report by IPC, an organization responsible for standardizing electronic connections, a staggering 90% of PCB failures can be traced back to manufacturing defects. This statistic emphasizes the critical nature of meticulous quality control processes throughout production. High-quality PCBs are essential for ensuring device reliability, reducing maintenance costs, and enhancing customer satisfaction.

Moreover, a study from Technavio predicts that the global printed circuit board market will grow by over $35 billion between 2021 and 2025. As demand increases, the need for dependable and high-quality manufacturing services becomes even more crucial. Companies that prioritize quality in their PCB assembly are more likely to achieve better performance and longevity in their products, which is vital in competitive markets. Adopting industry best practices and adhering to strict quality standards not only minimizes risks but also strengthens a company's reputation, ultimately impacting its bottom line.

When selecting a PCB manufacturing and assembly service provider, several key factors must be taken into account to ensure the highest quality and efficiency in production. One major consideration is the provider's technological capabilities. According to a recent industry report by IPC, over 75% of manufacturers prioritize advanced fabrication technologies, such as multilayer PCBs and high-density interconnect (HDI) designs. These cutting-edge capabilities are essential for developing complex electronics that meet today’s demanding performance standards.

Another critical factor is the provider’s quality assurance measures. A study conducted by the Electronics Manufacturing Services (EMS) Association revealed that companies with robust quality control processes experience up to 30% fewer defects in their PCBs. This not only helps in reducing rework costs but also speeds up time-to-market. Additionally, reviewing a provider's certifications, such as ISO 9001 and IPC-A-600, provides insight into their commitment to quality and industry standards. Such certifications can serve as a benchmark for reliability and operational excellence in PCB manufacturing and assembly, ultimately impacting the success of electronic products in the competitive market.

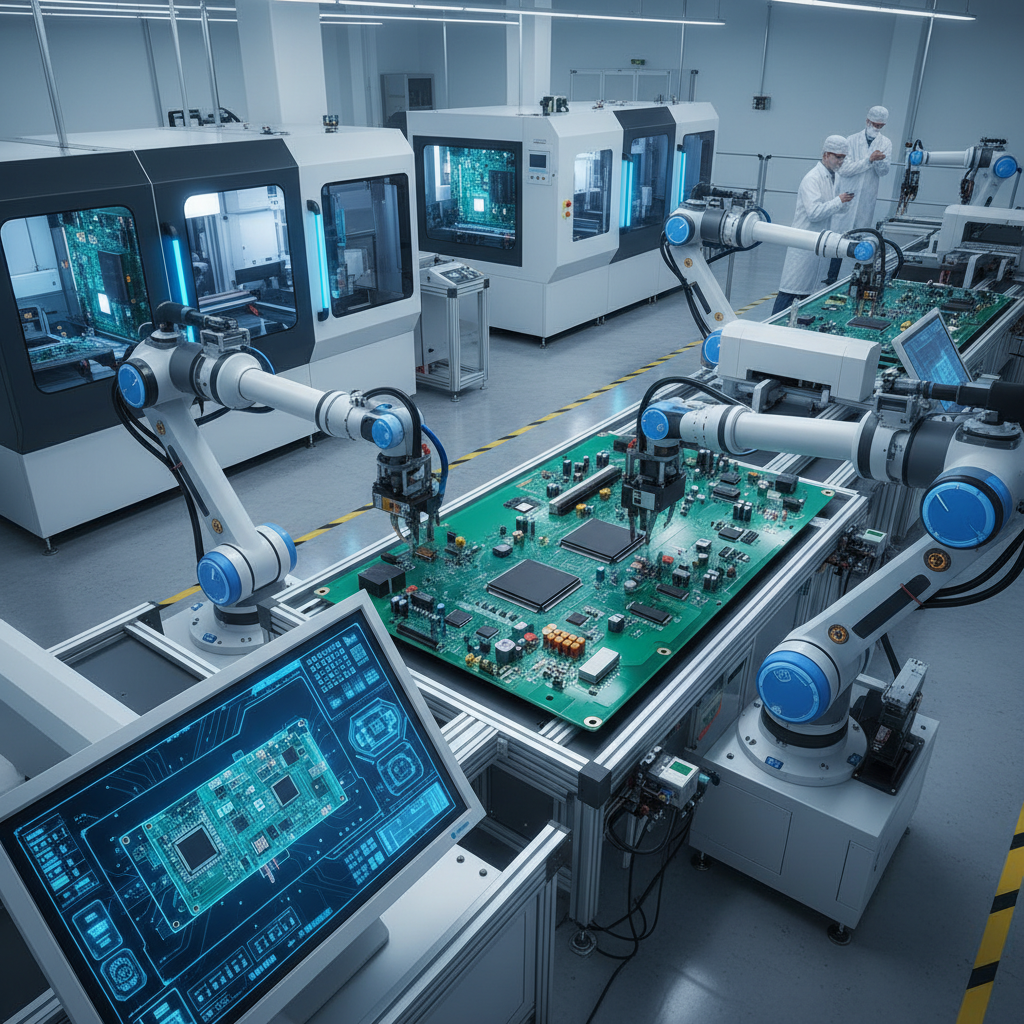

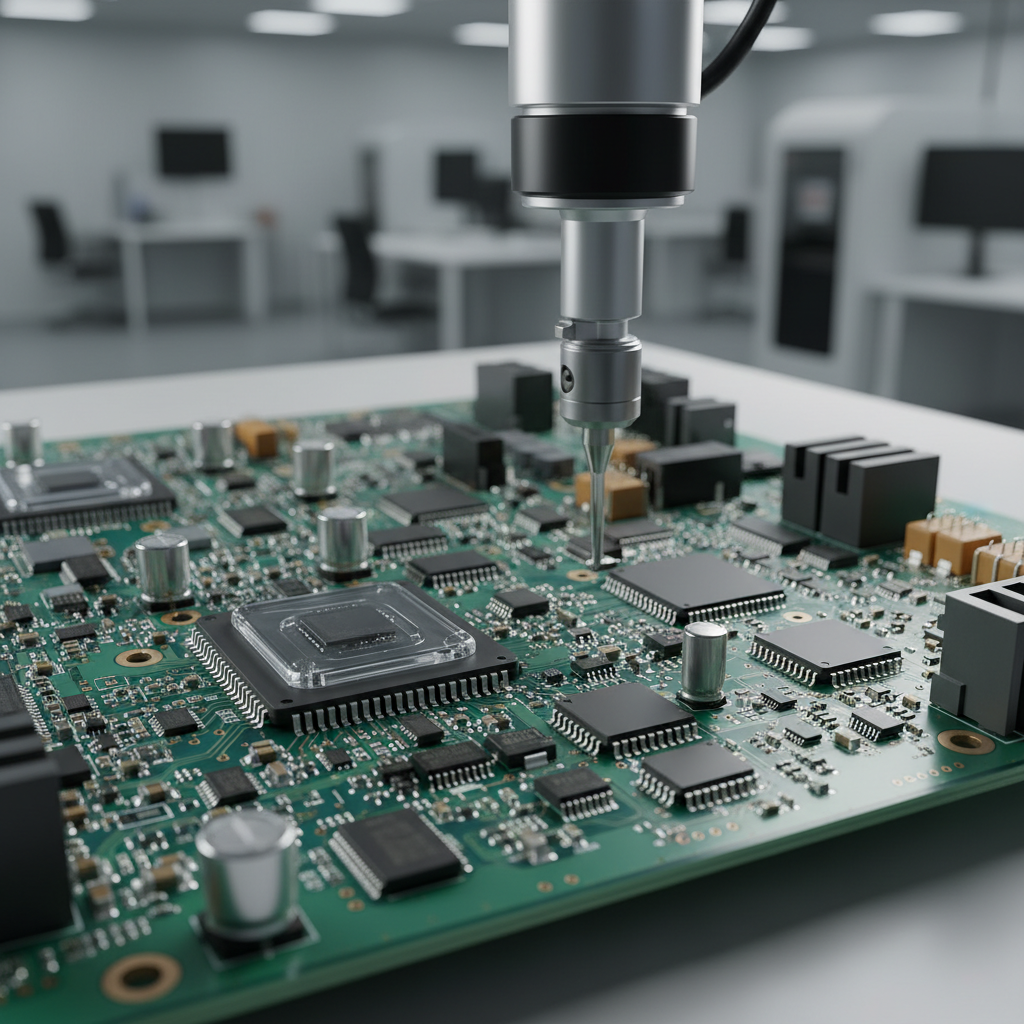

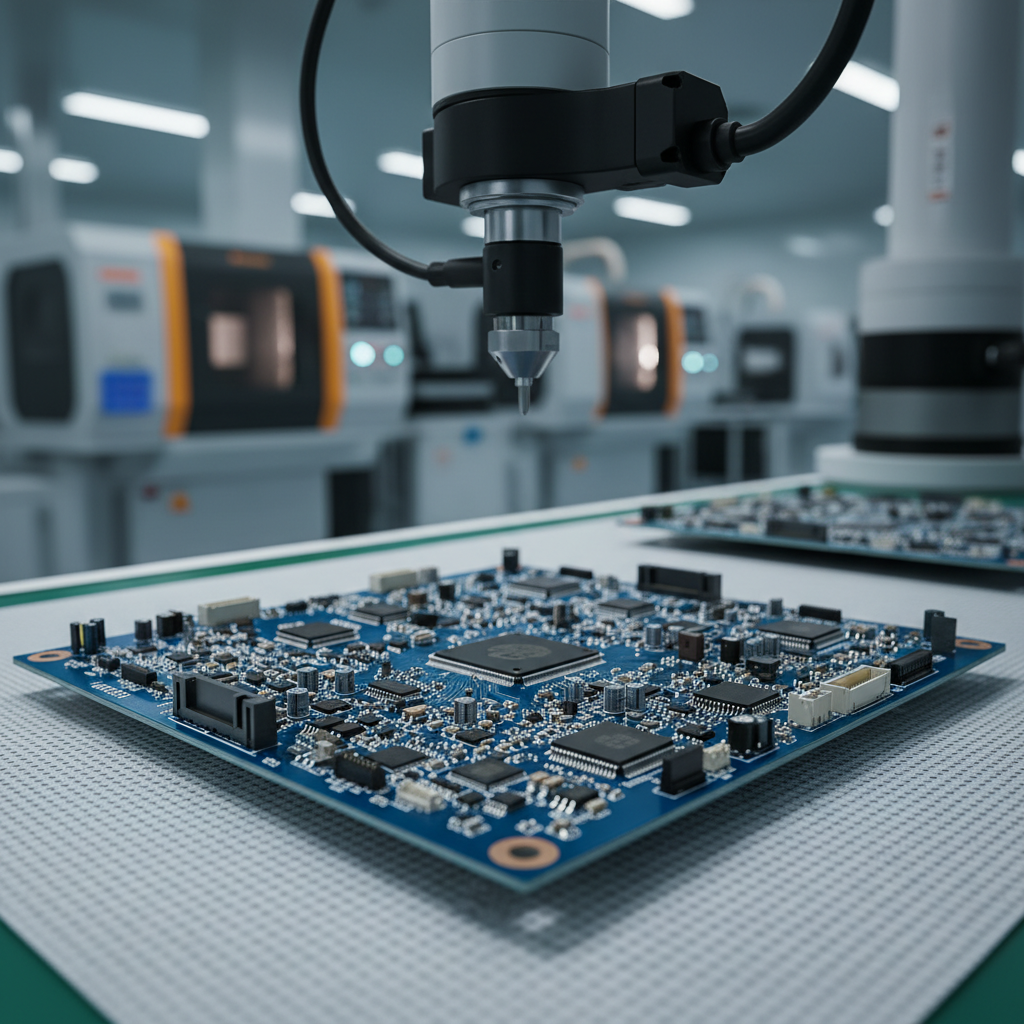

The rapid advancements in technology have significantly transformed PCB manufacturing efficiency, positioning it as a critical factor for businesses aiming to stay competitive in the market. According to a report by IPC—Association Connecting Electronics Industries, modern techniques such as robotic soldering and advanced inspection methods have led to a 30% reduction in manufacturing defects and a 20% increase in production speed. These enhancements ensure that companies can deliver high-quality products faster, meeting the rising consumer demand for innovation.

To leverage these technological advancements, companies should consider the following tips: First, invest in high-quality automation tools that can streamline processes and minimize manual errors. This not only saves time but also enhances overall workflow efficiency. Second, partner with PCB manufacturers who utilize state-of-the-art technology, ensuring that they are up to date with industry standards and innovations. Finally, regular training of staff on the latest technologies can significantly boost productivity and improve manufacturing outcomes.

By prioritizing the right PCB manufacturing and assembly services that incorporate these technological advancements, businesses can achieve greater efficiency, reduce costs, and maintain a competitive edge in the electronic marketplace.

When it comes to PCB manufacturing and assembly, businesses face the crucial decision of balancing cost and quality. While lower manufacturing costs may be enticing, sacrificing quality can lead to significant long-term issues. Flaws in PCBs can result in increased production times, product failures, and ultimately, dissatisfied customers. Therefore, it is important to carefully evaluate your options and choose a service that not only fits your budget but also maintains high standards of quality.

In a rapidly evolving market, such as the Dominican Republic, companies are emerging with the potential to enhance their roles in the global semiconductor and PCB value chains. This dynamic growth environment offers a promising alternative for businesses in search of cost-effective production solutions. However, firms must remain vigilant in assessing the capabilities and certifications of local manufacturers to ensure that quality is not compromised.

Tips: Always request samples and conduct quality inspections before committing to a manufacturer. Additionally, consider the long-term implications of your choices—sometimes investing a bit more upfront can save you significantly in maintenance and replacements down the line. Lastly, establish clear communication with your manufacturing partner to align your expectations on quality and delivery timelines.

In the realm of PCB manufacturing and assembly, customer support plays a pivotal role in determining service satisfaction levels. According to a report by the IPC (Institute for Printed Circuits), 78% of customers rated responsive support from their PCB providers as a key factor in their overall satisfaction. This highlights that not only the quality of the PCB itself is important, but also the accessibility and efficiency of customer service to address concerns and queries. Effective communication can greatly reduce lead times and minimize production errors, ultimately impacting project timelines and costs.

Moreover, a survey conducted by TechRepublic indicated that 67% of companies prioritize vendors that offer robust customer service programs over those with slightly lower prices. This trend underscores the growing realization that excellent customer support can significantly enhance the overall experience, fostering long-term partnerships and repeat business. In a competitive market where technological advancements are rapid, having a PCB service that prioritizes customer engagement and feedback can be a decisive advantage for businesses looking to innovate and expand.