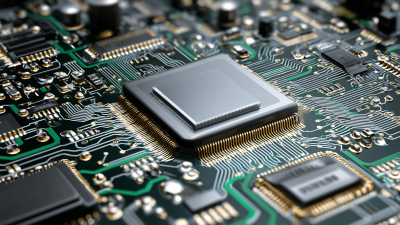

30+ Years of Experience in PCB Design and Manufacturing

In today's electronics-driven world, the demand for precision and reliability in electronics manufacturing is higher than ever. According to a recent industry report by the IPC Association, the global printed circuit board (PCB) market is projected to reach approximately $70 billion by 2025, driven by innovations in consumer electronics, automotive applications, and the expansion of the Internet of Things (IoT). As a crucial component in virtually every electronic device, the importance of efficient PCB manufacturing and assembly cannot be overstated.

Opting for professional PCB manufacturing and assembly services not only ensures that your projects meet high-quality standards but also significantly reduces the risks associated with production errors. A study from Mordor Intelligence indicates that the use of advanced manufacturing technologies can enhance production efficiency by up to 30%, resulting in faster time-to-market and lower costs for businesses. By leveraging the expertise and resources of professional services, companies are better positioned to navigate complex design challenges and adhere to industry regulations, leading to improved performance and customer satisfaction.

Ultimately, choosing professional PCB manufacturing and assembly services is a strategic investment that can drive innovation, enhance product reliability, and pave the way for the successful execution of projects across multiple sectors.

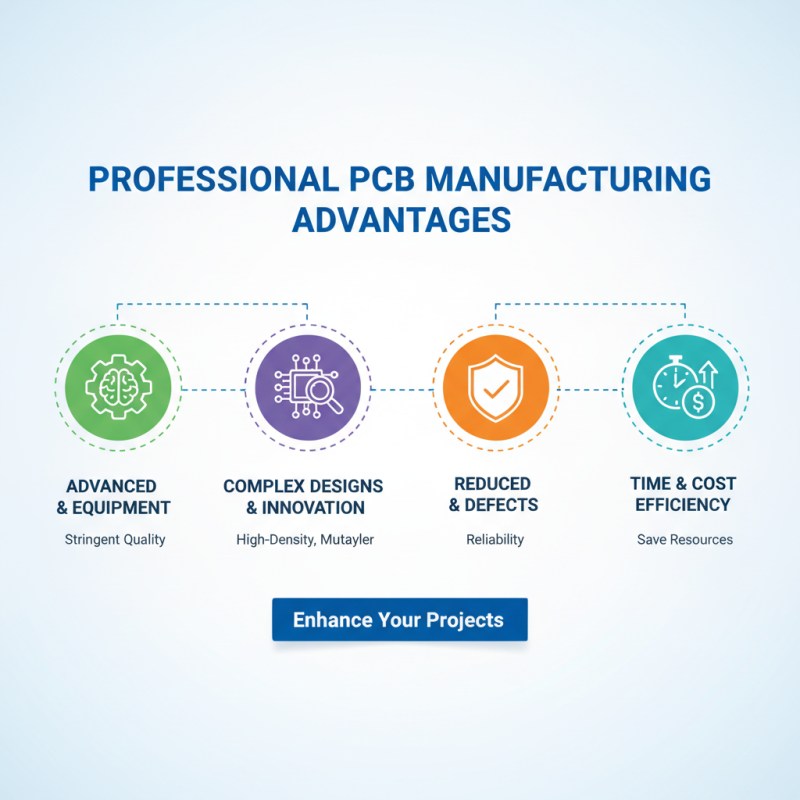

Choosing professional PCB manufacturing services offers numerous advantages that can significantly enhance the quality and efficiency of your projects. Firstly, these services come with advanced expertise and state-of-the-art equipment, ensuring that the PCBs produced meet stringent quality standards. Professional manufacturers are equipped to handle complex designs and can seamlessly integrate innovative technologies, which is particularly crucial for projects requiring high-density interconnects or multilayer boards. This level of specialization not only leads to superior product performance but also reduces the risks of errors and defects, saving time and resources in the long run.

Moreover, professional PCB manufacturers often provide comprehensive support throughout the entire production process. This includes assistance with design, prototyping, and testing, which helps in refining and optimizing the final product before mass production. Their ability to offer tailored solutions enables businesses to scale effectively while maintaining high product integrity. Additionally, these services tend to adhere to rapid turnaround times and can manage larger production volumes, facilitating quicker time-to-market for new innovations. Overall, investing in professional PCB manufacturing services not only elevates the technical quality of your projects but also streamlines the development process, driving greater success in competitive markets.

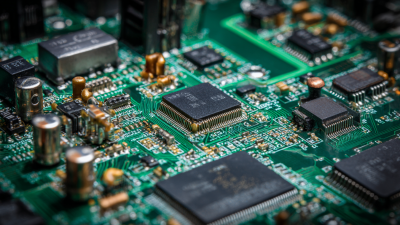

When selecting a PCB manufacturer, several key factors come into play that can significantly influence the success of your project. First and foremost, consider the manufacturer’s reputation and experience in the industry. A reliable manufacturer should have a proven track record of delivering high-quality products on time. Look for customer testimonials and case studies that demonstrate their capability to handle projects similar to yours. It's essential to partner with a company that understands the unique needs of your sector and adheres to relevant quality standards.

Another critical aspect to evaluate is the range of services offered by the manufacturer. Many PCB projects require not just fabrication but also assembly, testing, and support services. Choosing a manufacturer that can provide a comprehensive suite of services under one roof can streamline your supply chain and reduce lead times. Additionally, assess the technologies and equipment they utilize. Advanced manufacturing processes can lead to better precision, lower error rates, and improved product durability.

**Tips:** Always inquire about the manufacturer's commitment to quality control. Understanding their inspection processes and certifications can help you gauge the reliability of the final product. Furthermore, don’t hesitate to ask about their turnaround times and their flexibility to adapt to changing project requirements. Establishing a strong communication channel with your chosen PCB manufacturer can also foster a collaborative relationship, ensuring your project runs smoothly from start to finish.

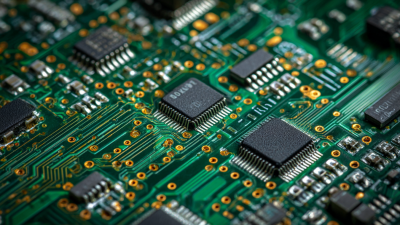

Quality control in PCB assembly is paramount for ensuring that electronic devices perform reliably and efficiently. During the manufacturing process, various factors such as temperature, soldering techniques, and component placement can significantly affect the final product's integrity. Implementing robust quality control measures allows manufacturers to identify and rectify defects before they escalate into costly failures. By utilizing advanced inspection technologies, such as automated optical inspection (AOI) and X-ray tomography, companies can effectively detect misalignments, solder defects, and component placement errors.

Moreover, rigorous testing throughout the PCB assembly process helps maintain high performance standards. This includes electrical testing, thermal analysis, and functional verification, ensuring that each PCB meets specific operational criteria. By prioritizing quality control, manufacturers can enhance the reliability of their products, leading to increased customer satisfaction and reduced warranty claims. The investment in quality control not only streamlines production but also establishes a foundation of trust between the manufacturer and the client, reinforcing the importance of delivering high-quality electronic solutions in a competitive market.

When embarking on a project that requires printed circuit boards (PCBs), opting for professional manufacturing and assembly services can significantly impact your budget. Data from industry reports indicate that companies leveraging professional PCB services experience cost reductions of up to 30% compared to in-house production when factoring in material waste, labor costs, and potential rework due to quality issues. This cost-effectiveness not only stems from economies of scale but also from the specialized expertise and advanced technology employed by established PCB manufacturers.

Moreover, professional services can expedite your project timeline, allowing for faster product launches and the ability to respond to market demands swiftly. According to a survey from the IPC, nearly 60% of electronics manufacturers reported that outsourcing PCB production improved their operational efficiency. By outsourcing, companies can focus their resources on core competencies while ensuring high-quality standards in PCB assembly.

Tips: When choosing a PCB service provider, consider their industry certifications and customer reviews. Additionally, ensure that they practice lean manufacturing to minimize waste and enhance cost savings. Regular communication with your chosen manufacturer can also lead to better alignment on project specifications, potentially reducing costs associated with miscommunication.

| Service Type | Cost per Unit ($) | Lead Time (Days) | Quality Rating (1-5) | Order Volume (Units) |

|---|---|---|---|---|

| Prototype Manufacturing | 75 | 5 | 4 | 50 |

| Small Batch Production | 50 | 10 | 5 | 100 |

| Mass Production | 25 | 15 | 5 | 1000 |

| Assembly Services | 30 | 7 | 4 | 200 |

| Quick Turn Service | 90 | 3 | 4 | 20 |

In today's fast-paced technological landscape, the demand for efficient and reliable printed circuit board (PCB) manufacturing and assembly services is pivotal for successful project execution. According to a report by IPC, the global PCB market is projected to reach $87 billion by 2025, driven by the increasing complexity of electronic devices and the need for miniaturization. By choosing professional PCB manufacturing services, businesses can leverage advanced techniques and equipment that not only save time but also enhance overall project efficiency.

Expert PCB solutions provide a myriad of benefits that streamline project workflows. For instance, a study from ResearchAndMarkets highlights that companies employing specialized PCB assembly services can reduce time-to-market by up to 30%. This is primarily achieved through optimized design processes, precision manufacturing, and thorough quality inspections that eliminate the risks of costly errors. Furthermore, professional services often offer scalable solutions to accommodate varying project sizes, ensuring that teams can allocate resources effectively and maintain productivity throughout different stages of development. In a competitive environment, choosing expert PCB solutions is vital for meeting project timelines while maintaining high standards in both functionality and reliability.