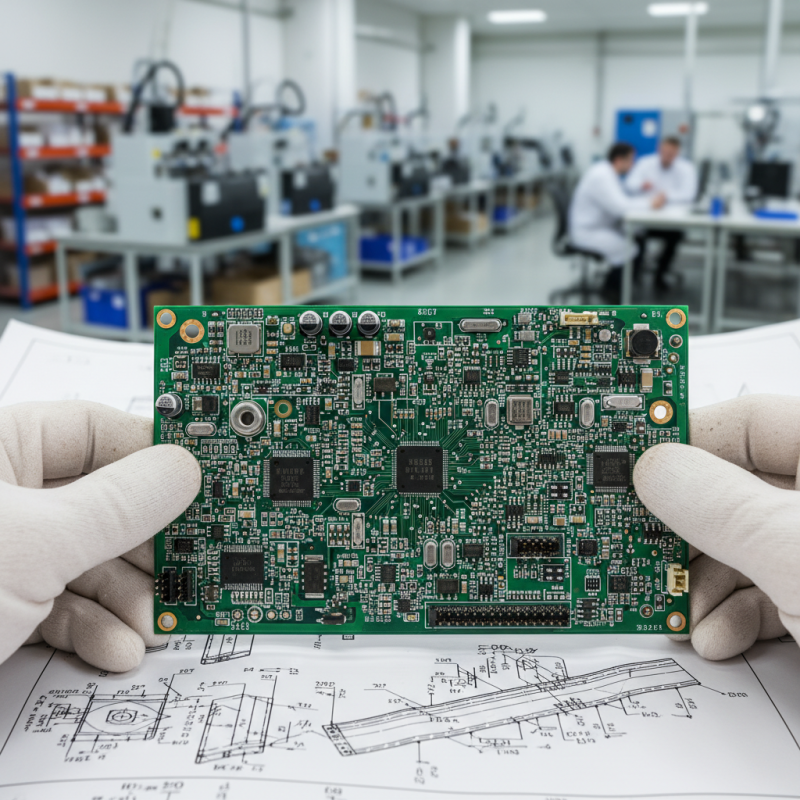

30+ Years of Experience in PCB Design and Manufacturing

In the ever-evolving landscape of electronics manufacturing, obtaining a competitive PCB quote has become an essential step for businesses aiming to stay ahead in the market. With an increasing demand for high-quality printed circuit boards, understanding the nuances that influence pricing can provide considerable leverage in negotiations. This article will explore effective strategies to secure the best PCB quote, ensuring you not only receive favorable pricing but also maintain the quality standards necessary for your projects.

Navigating the complexities of PCB pricing requires a combination of knowledge and preparation. Factors such as material costs, manufacturing techniques, and order quantities all play pivotal roles in determining the final quote. By being well-informed and ready to communicate your specific needs to potential suppliers, you can enhance your chances of obtaining a competitive quote that aligns with your project’s requirements. Throughout this guide, we will delve into key tips and insights, enabling you to ask the right questions and make informed decisions in your search for the ideal PCB quote.

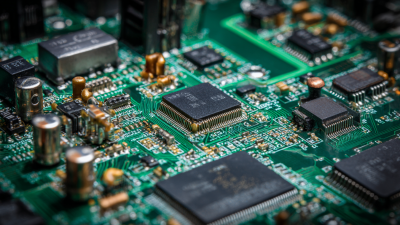

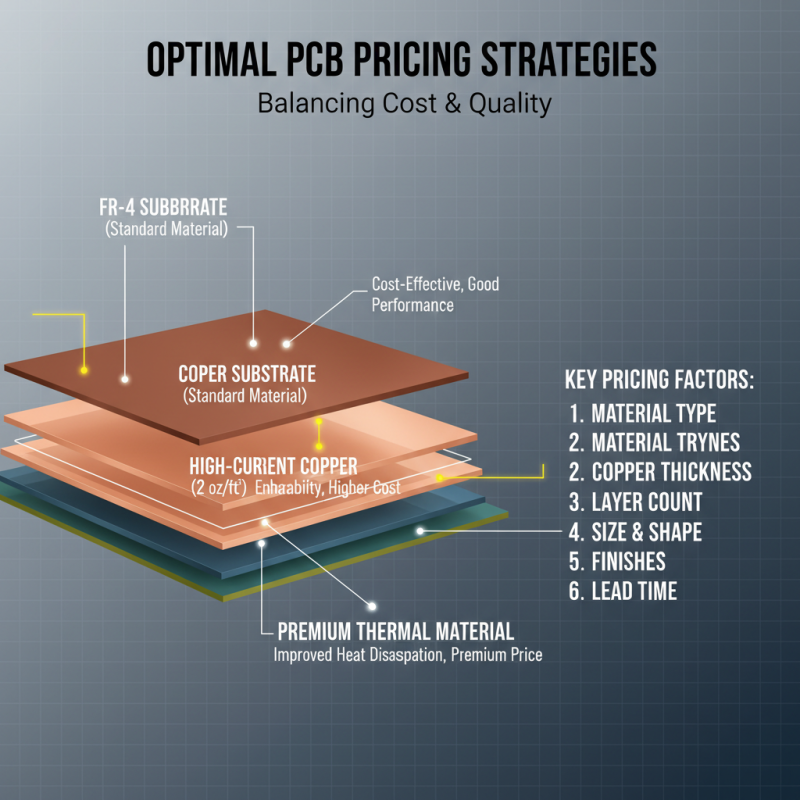

When seeking a competitive PCB quote, understanding the pricing factors is crucial for making informed decisions that balance quality and cost. One of the primary elements influencing PCB pricing is the material used. Common materials like FR-4 offer a good balance of performance and price, while premium materials can enhance durability and thermal management but come with higher costs. Aspects like the thickness of the copper used also affect pricing; thicker copper layers can improve the board's performance in high-current applications but will increase the total manufacturing expense.

Another significant factor is the size of the PCB. Larger boards generally require more raw material and longer manufacturing times, which could lead to increased costs. Additionally, the complexity of the design plays a pivotal role in pricing. PCBs with intricate layouts, tight tolerances, or multiple layers necessitate advanced manufacturing processes, all contributing to higher quotes. Lastly, the volume of PCBs ordered can heavily influence the price per unit; higher quantities often lead to economies of scale, resulting in lower costs per board. Therefore, when requesting quotes, it’s essential to specify these factors clearly to receive accurate estimates that align with your project requirements.

When selecting a PCB manufacturer, assessing quality certifications and industry reputation is critical for ensuring you receive the best product for your investment. Manufacturers often pursue various certifications—such as ISO 9001, IPC-A-600, and IPC-6012—which signify adherence to international quality standards. A recent report from the IPC (Institute of Printed Circuits) highlighted that companies with these certifications tend to experience 30% fewer product defects, leading to significant cost savings in production and rework.

It's essential to compare manufacturers not only based on their pricing but also on their track record in quality management. Services like IPC's Validation Services can help verify a manufacturer's capabilities and commitment to quality. A manufacturer's reputation can be assessed through customer reviews and industry standing, often reflected in their years of experience and client portfolio. In fact, recent surveys indicate that 70% of engineers consider a manufacturer’s reputation as a top criterion for selection.

Tips: To get the most competitive quote while ensuring quality, always ask for a detailed breakdown of the costs associated with the PCB manufacturing process. Evaluating factors like lead times, material sourcing, and production techniques can provide deeper insights into the overall quality and reliability of the service. Additionally, requesting samples before placing larger orders can help verify that the manufacturer meets your specific standards and needs.

When evaluating PCB lead times, it's crucial to understand the profound impact that manufacturing speed has on pricing and delivery.

According to a report by IPC, the association connecting electronics industries, approximately 50% of PCB manufacturers consider lead times as a critical factor influencing their pricing structures.

Shorter lead times often mean higher costs due to the need for expedited production; however, they can significantly benefit companies requiring rapid prototyping or urgent market entry.

In addition to pricing implications, lead times can also affect supply chain dynamics.

A 2022 survey by Statista revealed that around 60% of electronics firms reported increased delays in PCB delivery times due to global supply chain disruptions.

This emphasizes the importance of selecting manufacturers with reliable timelines and transparency in their production schedules.

Ultimately, understanding how lead times influence both the cost and the strategic planning of PCB procurement is essential for businesses aiming to maintain competitiveness in a fast-paced market.

Negotiating PCB quotes can significantly impact your manufacturing costs and overall project budget. A recent report by IPC revealed that nearly 66% of manufacturers consider competitive pricing to be a crucial factor when selecting suppliers for printed circuit boards (PCBs). To effectively negotiate quotes, it is essential to convey clear specifications and requirements. This not only ensures that you receive accurate estimates but also helps suppliers understand the potential for long-term collaboration.

Moreover, leveraging data is key to achieving cost-effective solutions. An industry study published by Research and Markets found that optimizing the procurement process could reduce PCB costs by up to 15%. When discussing quotes, present comparative data on material costs, production times, and quality standards that demonstrate your awareness of market trends. This not only strengthens your negotiating position but also encourages suppliers to offer better terms. Utilizing techniques such as bulk ordering or flexible delivery timelines can also lead to savings. By taking a strategic approach to negotiations, companies can secure high-quality PCBs at favorable prices while fostering strong relationships with their suppliers.

In today's competitive electronics market, utilizing advanced software tools for PCB cost estimation can significantly enhance both pricing strategies and quality assurance. Recent industry reports indicate that manufacturers who employ software-driven estimation techniques can reduce their cost estimation time by up to 50%, leading to quicker decision-making and improved efficiency in the PCB design process. This technological advancement allows companies to take into account various factors affecting pricing, including materials, labor, and complexity, providing a more accurate and reliable quote.

To optimize the benefits of these software tools, it's essential to implement several best practices. First, always keep your component libraries updated, as outdated data can lead to miscalculations and inflated costs. Second, utilize simulation features available in many PCB design tools to anticipate potential manufacturing issues and adjust your design accordingly, preventing costly revisions later on. Lastly, do not overlook the importance of collaboration; integrate your software with project management tools to ensure that communication among teams is seamless, which further streamlines the quoting process.

By adopting these practices and leveraging technology, businesses can not only enhance their cost estimation accuracy but also ensure that they remain competitive in pricing while maintaining high-quality standards. This strategic use of software tools positions companies to respond effectively to market demands and customer expectations.