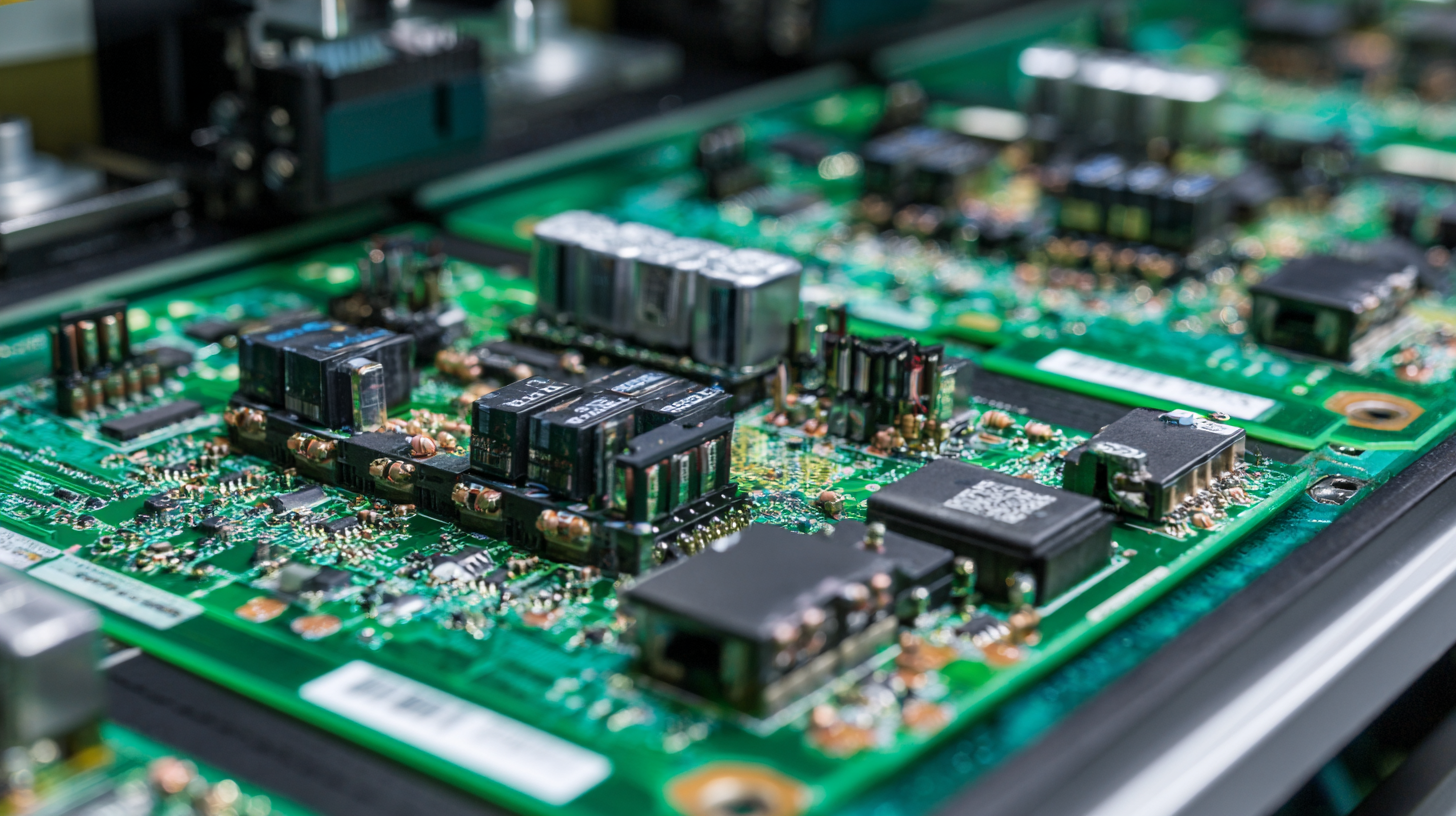

30+ Years of Experience in PCB Design and Manufacturing

In the rapidly advancing field of electronics, the significance of effective PCB production techniques cannot be overstated. As reported by the IPC, the global PCB market is expected to grow to $83 billion by 2027, highlighting the increasing demand for high-quality, efficient production methods. To stay competitive, manufacturers must adopt innovative approaches that enhance both efficiency and quality in their PCB production processes.

Renowned industry expert Dr. Alice Monroe, a leading authority in PCB manufacturing technologies, emphasizes the importance of operational excellence: "Streamlining PCB production not only reduces costs but also significantly improves product reliability." Her insights underscore the critical need for businesses to implement best practices and adopt cutting-edge technologies to meet both market demands and customer expectations.

This article will explore the top ten PCB production techniques that will enable companies to optimize their operations, ensuring superior quality and efficiency in an ever-evolving marketplace. By leveraging these methods, manufacturers can secure their position as frontrunners in the highly competitive realm of PCB production.

The quest for enhanced PCB longevity and performance has driven significant advancements in materials and production techniques. The recent discussions at an Innovation Symposium highlighted the emergence of halogen-free materials, aligning with the industry's growing emphasis on environmental safety. These materials not only support eco-friendly electronics but also offer improved thermal management in devices, addressing the dual challenges of performance and sustainability. In fact, the market for rigid flex PCBs was valued at USD 3.62 billion in 2024 and is projected to experience a CAGR of 12.4%, indicating a robust demand for innovative designs that incorporate these advanced materials.

Moreover, the development of aluminium PCBs is revolutionizing thermal management in electronic applications. By efficiently dissipating heat, these new materials enhance the durability and reliability of devices, which is critical as technology continues to miniaturize. Additionally, the ultra-thin flexible PCB market is set to grow at a CAGR of 11.20%, showcasing a trend towards more adaptable and efficient manufacturing solutions. As the industry pivots to embrace these innovative materials, the focus on sustainable practices and enhanced performance will undoubtedly shape the future of electronics manufacturing.

The electronics industry is witnessing a transformative shift with the adoption of automated processes in PCB production. These advancements not only streamline manufacturing workflows but also significantly increase throughput. By integrating cutting-edge technologies such as robotic arms and automated pick-and-place systems, manufacturers can optimize various stages of production. This evolution allows for faster assembly times, reduced labor costs, and minimal human errors, which ultimately leads to superior quality in the final product.

Moreover, automation enhances flexibility in PCB production. Manufacturers can easily adjust their production lines to accommodate different designs or volume requirements without extensive reconfiguration. This adaptability is crucial in responding to the fast-paced demands of the market. Additionally, real-time monitoring systems facilitate data collection and analysis, enabling continuous improvement and quick identification of potential issues in the production process. As a result, the PCB production landscape is evolving towards a more efficient, high-quality framework, driven largely by automated processes that redefine what is possible in electronics manufacturing.

When it comes to ensuring the quality and reliability of PCB production, advanced testing methods play a crucial role. Techniques such as Automated Optical Inspection (AOI) and X-ray inspection allow manufacturers to detect defects that are invisible to the naked eye. These methods enhance the accuracy of inspections, ensuring that every component meets stringent quality standards before moving on to the next production stage.

One key tip is to integrate real-time testing within the production line. This approach reduces the time spent on post-production tests and allows for immediate corrections if issues are detected. Additionally, adopting burn-in testing can help identify weak components early, ultimately increasing the product's longevity and reliability.

Another important aspect is the use of Statistical Process Control (SPC). By monitoring various production parameters, manufacturers can identify trends that may lead to defects. Regular audits and data analysis can reveal insights that facilitate continuous improvements. Implementing these advanced testing strategies not only enhances product quality but also boosts overall production efficiency.

In recent years, environmental considerations have become increasingly vital in PCB (Printed Circuit Board) manufacturing techniques. As the demand for electronic devices continues to rise, the industry faces substantial pressure to minimize its environmental footprint. Implementing eco-friendly practices, such as using lead-free solder and reducing hazardous waste, is essential for manufacturers aiming to comply with stringent regulations and promote sustainability. By adopting green manufacturing processes, companies can not only contribute positively to the environment but also enhance their brand reputation among eco-conscious consumers.

Another crucial aspect of environmentally friendly PCB production is the efficient use of resources and energy. Techniques that focus on reducing material waste, such as advanced photolithography and optimized panel layout designs, can significantly decrease the environmental impact of PCB manufacturing. Additionally, employing renewable energy sources in the manufacturing process can further mitigate ecological effects. By investing in such innovative approaches, manufacturers can achieve improved efficiency and quality while aligning with global sustainability goals, ultimately leading to a more responsible and forward-thinking industry.

The integration of smart technologies in PCB design and fabrication represents a significant leap towards enhancing efficiency and quality. By leveraging advanced software tools that utilize artificial intelligence and machine learning, designers can simulate and optimize layouts before actual production. This predictive capability reduces errors and minimizes material waste, ultimately leading to more sustainable practices in PCB manufacturing. Additionally, these technologies enable better collaboration among teams, streamlining workflows and communication in real-time.

Moreover, the incorporation of IoT (Internet of Things) devices facilitates a more connected production environment. Smart machines equipped with sensors can monitor and adjust parameters during the manufacturing process, ensuring precision and consistency. This level of automation not only improves productivity but also allows for immediate detection and correction of deviations from quality standards. As a result, manufacturers can achieve higher throughput while maintaining the integrity and performance of the PCBs produced. By embracing these innovative technologies, the PCB industry is positioned to meet the growing demands for advanced electronics with unparalleled efficiency and quality.