30+ Years of Experience in PCB Design and Manufacturing

In the ever-evolving world of electronics, selecting the right PCB board is crucial. Renowned industry expert Dr. Emily Carter once stated, "The quality of a PCB board can make or break a project." This insight highlights the importance of choosing the right type for specific needs.

Different applications require various PCB board types, each with unique characteristics. For example, high-frequency applications need specialized boards that minimize signal loss. Understanding these differences is vital for engineers and designers. Many professionals overlook the significance of thermal management in PCB board design. This oversight can lead to overheating and failure in critical devices.

As we delve into the best PCB board types for 2026, it's essential to consider both emerging technologies and traditional methods. The landscape is crowded, and the choices can be overwhelming. But with the right knowledge, making informed decisions becomes easier. This guide aims to provide clarity and insights to navigate this complex field effectively.

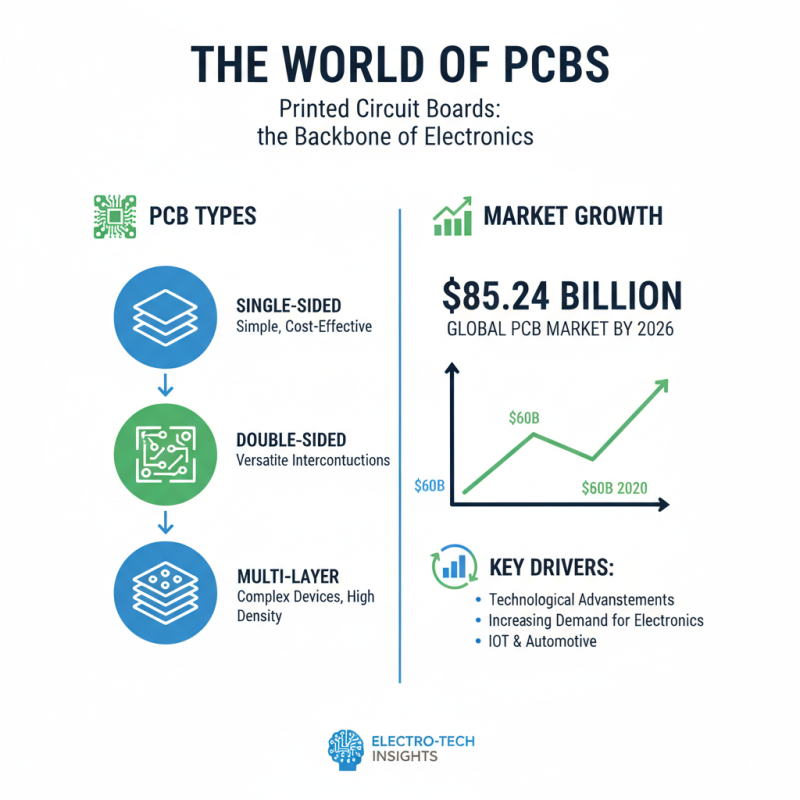

Understanding PCB types is essential for anyone in electronics. Printed Circuit Boards (PCBs) are critical components in virtually all electronic devices. They provide the electrical connection and mechanical support for components. According to a recent industry report, the global PCB market is projected to reach $85.24 billion by 2026. This growth reflects the increasing demand driven by advancements in technology.

There are various PCB types, each serving different purposes. Rigid PCBs are the most common, used in everyday electronics. Flexible PCBs offer versatility, allowing for unique shapes and designs. According to a study, flexible PCBs can reduce assembly costs by up to 30%. On the other hand, rigid-flex boards combine both rigid and flexible properties, providing durability where needed.

**Tips:** When choosing a PCB type, consider the specific application. Think about design complexity and cost-effectiveness. It's crucial to evaluate if standard options meet your needs. Sometimes, custom solutions may provide better long-term value. Not all designs require cutting-edge technology. Do not overlook simpler PCBs for basic projects. Reflecting on your requirements can lead to better decisions.

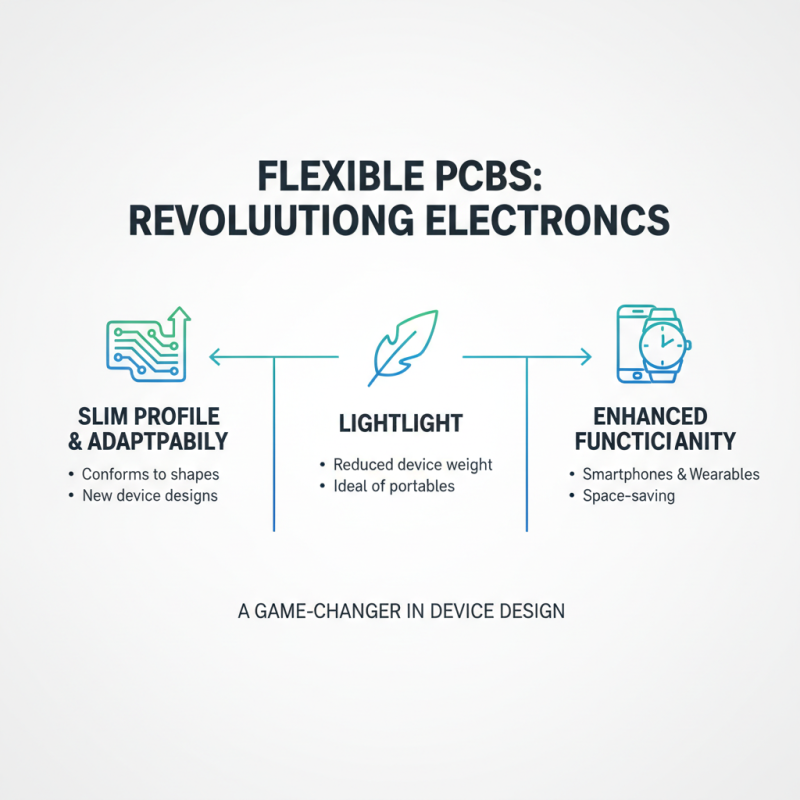

Flexible PCBs are revolutionizing the electronics industry. They offer a slim profile and adaptability that rigid boards cannot match. These boards can easily conform to various shapes, which is a game-changer in device design. Their lightweight nature helps reduce the overall weight of devices, making them ideal for portable applications. In smartphones and wearables, flexible PCBs are enhancing functionality without compromising on space.

The benefits of using flexible PCBs extend beyond their physical characteristics. They can withstand mechanical stresses better than traditional boards. This is vital for modern applications, where devices often face wear and tear. However, there are challenges. Not all designs will benefit from flexible boards. The manufacturing process can be more complex and costly. Designers must weigh these factors carefully. As technology progresses, the opportunities for flexible PCBs are expanding. They hold great potential, but careful planning is essential for success.

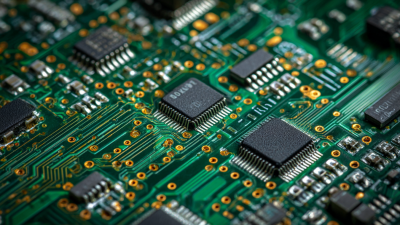

Rigid printed circuit boards (PCBs) are crucial in consumer electronics. They provide a stable platform for components. These boards are made from solid materials like fiberglass or epoxy resin. This ensures durability and reliability in various devices, from smartphones to home appliances.

Industry reports suggest that the rigid PCB market is expected to grow significantly. In recent years, the growth rate was around 5% annually. However, challenges exist—especially in meeting increasing demands for miniaturization. Many manufacturers struggle to maintain quality while reducing sizes. Smaller components can lead to overheating issues or signal interference.

Consumer expectations are rising, demanding thinner and lighter devices. Rigid PCBs are adapting to these needs. Advancements in materials and manufacturing processes are essential. It's a balancing act between functionality and design. The exploration of new materials may provide solutions. However, costs may rise due to innovative techniques. Rigid PCBs must continue to evolve amidst these pressures.

| PCB Type | Characteristics | Common Uses | Advantages | Limitations |

|---|---|---|---|---|

| Rigid PCB | Solid substrate, can handle high temperatures | Consumer electronics, automotive, medical devices | Durability, stability, and high assembly density | Limited flexibility; difficult to repair |

| Flexible PCB | Bendable and lightweight, allows for dynamic applications | Wearable technology, smart devices, compact electronics | Space-saving, improves performance in tight areas | Higher production costs, less durability |

| Rigid-Flex PCB | Combination of rigid and flexible elements | Aerospace, military, advanced medical technology | Highly customizable, excellent reliability | Complex design, expensive to manufacture |

| Double-Sided PCB | Conductive paths on both sides | High-frequency circuits, audio devices | Better for heat dissipation, more circuit density | More complex to manufacture, higher cost |

| Multilayer PCB | Three or more layers of conductive material | High-density applications, telecommunications | Extremely compact, suitable for complex designs | Difficult to troubleshoot, higher production costs |

Rigid-Flex PCBs are increasingly gaining attention in the electronics industry. These boards combine the benefits of both rigid and flexible designs. According to a report, the market for rigid-flex PCBs is projected to grow at a CAGR of approximately 8.5% from 2021 to 2026. This growth is driven by the demand for compact and lightweight electronic devices.

In practical applications, rigid-flex PCBs offer improved reliability in challenging environments. They can withstand movement and vibration, making them ideal for aerospace, medical, and automotive industries. For consumer electronics, their versatility allows for innovative designs that maximize space without sacrificing performance. However, they can be more challenging to manufacture, potentially leading to increased costs and longer lead times.

Tips: Consider the layout carefully. Ensure that the transition areas between rigid and flexible sections are well-defined. Testing prototypes is crucial. Early detection of design flaws can save time and resources. Flexibility might lead to unforeseen issues in durability. Balancing these factors is essential for successful implementation.

Choosing the right PCB type for your project is crucial. Start by identifying your project's requirements. Consider dimensions, weight, and environmental factors. Some PCBs are better for high temperatures. Others work well in flexible designs. Each choice has its trade-offs.

Material selection also plays an important role. For instance, FR-4 is a common choice for many applications. However, it may not suit high-frequency tasks. Flexibility can be essential for wearable gadgets. Look at materials like polyimide when you need that. For complex designs, you might need multilayer PCBs. They can offer more functionality in a smaller size.

Don't forget about the manufacturing process. Some PCBs need more precise techniques. This may raise costs or complicate timelines. Research various fabrication methods. Ask yourself if you can compromise on certain aspects. It's normal to feel overwhelmed with options. Reflecting on your specific needs will guide you through the choices.

This chart illustrates the popularity of different types of PCB boards in various electronic applications in 2026. The data is based on industry trends and usage statistics.