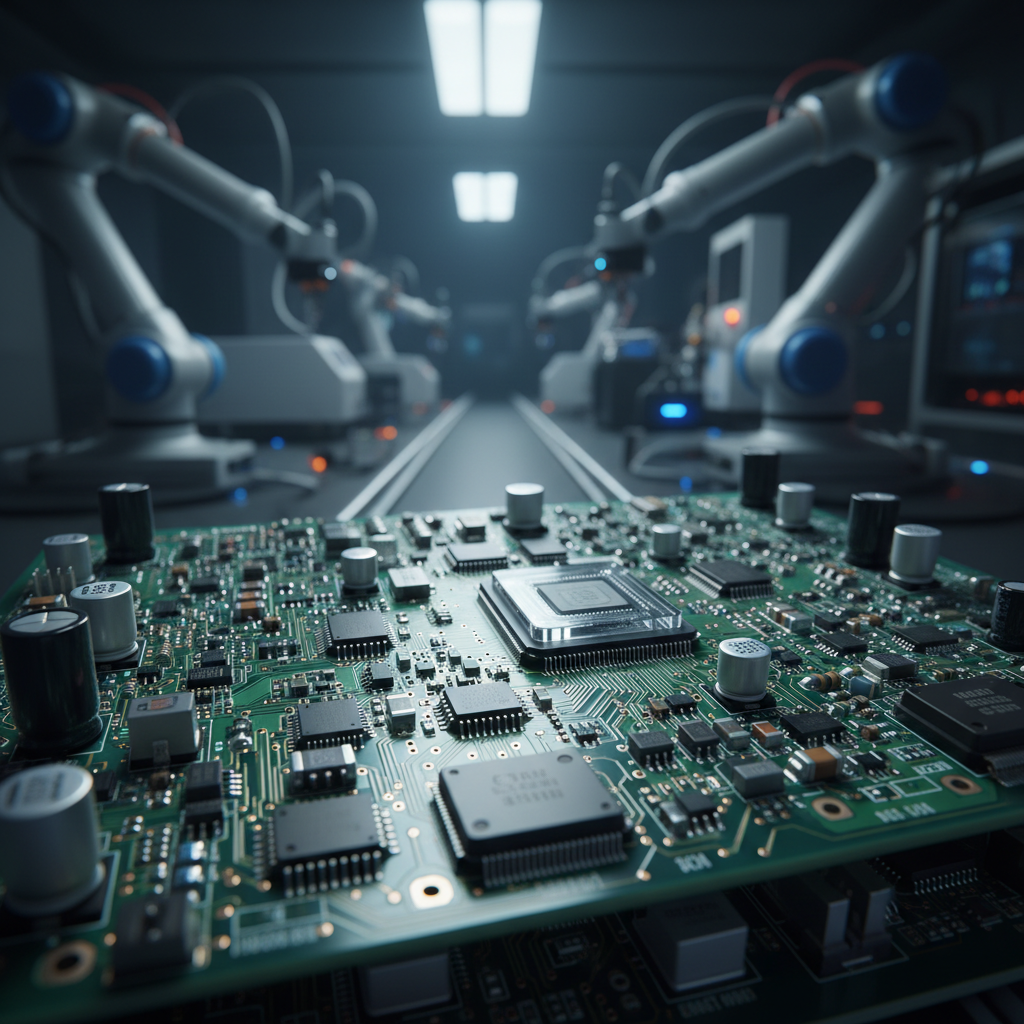

30+ Years of Experience in PCB Design and Manufacturing

In the rapidly evolving landscape of electronics, the significance of printed circuit board assembly (PCBA) cannot be overstated. Research indicates that the global PCB market is projected to reach approximately $100 billion by 2025, driven by the increasing demand for electronic devices across various sectors, including consumer electronics, automotive, and industrial applications. As a fundamental component of electronic products, PCBAs enable the interconnectedness of different electronic elements, making them integral to both functionality and design efficiency.

The advantages of utilizing printed circuit board assembly in electronics projects are manifold. Firstly, PCBA enhances reliability due to its meticulous manufacturing processes, which ensure that components are securely attached and minimizes the risk of failure. Moreover, developments in automation and advanced manufacturing technologies have led to reduced production costs, making it economically viable for projects of all scales. The strategic incorporation of PCBA not only shortens time-to-market but also provides significant opportunities for innovation, allowing designers to push the boundaries of what is possible in their electronic creations.

As industry professionals continuously look for ways to optimize production and improve quality, understanding the top benefits of printed circuit board assembly becomes essential for successfully navigating the electronics market in the coming years. Embracing these advantages can open new avenues for efficiency and creativity in the development of groundbreaking electronic solutions.

Printed Circuit Board (PCB) assembly plays a crucial role in modern electronics, particularly in enhancing design flexibility for complex applications. By utilizing advanced fabrication techniques, designers can create bespoke circuit layouts that meet the intricate requirements of their projects. This flexibility allows engineers to incorporate multiple functionalities into a compact design, optimizing space and performance. As electronic devices become increasingly sophisticated, the ability to modify and customize PCB layouts enables the integration of cutting-edge technologies, such as IoT and smart systems.

Moreover, the modular nature of PCB assembly allows for easier iterations during the design process. Prototyping can be rapidly conducted, with adjustments made to the circuit design based on testing outcomes. This iterative approach fosters innovation, as designers can experiment with various configurations without the constraints of traditional wiring methods. Ultimately, the enhanced design flexibility provided by PCB assembly paves the way for the development of more reliable, efficient, and versatile electronic solutions, significantly benefitting the evolving landscape of technology.

The efficiency of production processes in electronics manufacturing significantly improves with Printed Circuit Board Assembly (PCBA). According to a report by IPC, companies that utilize advanced PCB assembly technology can reduce their production time by up to 30%. This increase in efficiency not only accelerates the time to market but also enhances the ability to respond to changing consumer demands. By streamlining the assembly process through methods such as automated pick-and-place systems and surface mount technology, manufacturers can achieve higher throughput while maintaining quality standards.

Cost-effectiveness is another critical advantage of PCBA. A study by Market Research Future indicates that the global PCB market is projected to grow at a CAGR of 3.9%, largely driven by the demand for cost-efficient manufacturing solutions. By optimizing the assembly process through precise component placement and minimizing material waste, businesses can significantly lower their production costs. Moreover, using PCBA allows for better inventory management, as finished assemblies can be produced in batch runs according to demand, further reducing overall expenses and maximizing resource utilization.

| Benefit | Description | Impact on Project |

|---|---|---|

| Improved Production Efficiency | Streamlined assembly process reduces time needed for production. | Faster time-to-market for electronic products. |

| Cost-Effectiveness | Lower labor costs and reduced material waste contribute to savings. | Increased profit margins on products. |

| Enhanced Design Flexibility | Allows for complex designs and miniaturization of components. | Greater innovation in product development. |

| Quality Control | Regular inspection and testing ensure high standards. | Reduces failure rates and improves customer satisfaction. |

| Scalability | Facilitates easy scaling up or down of production runs. | Flexibility to respond to market demands. |

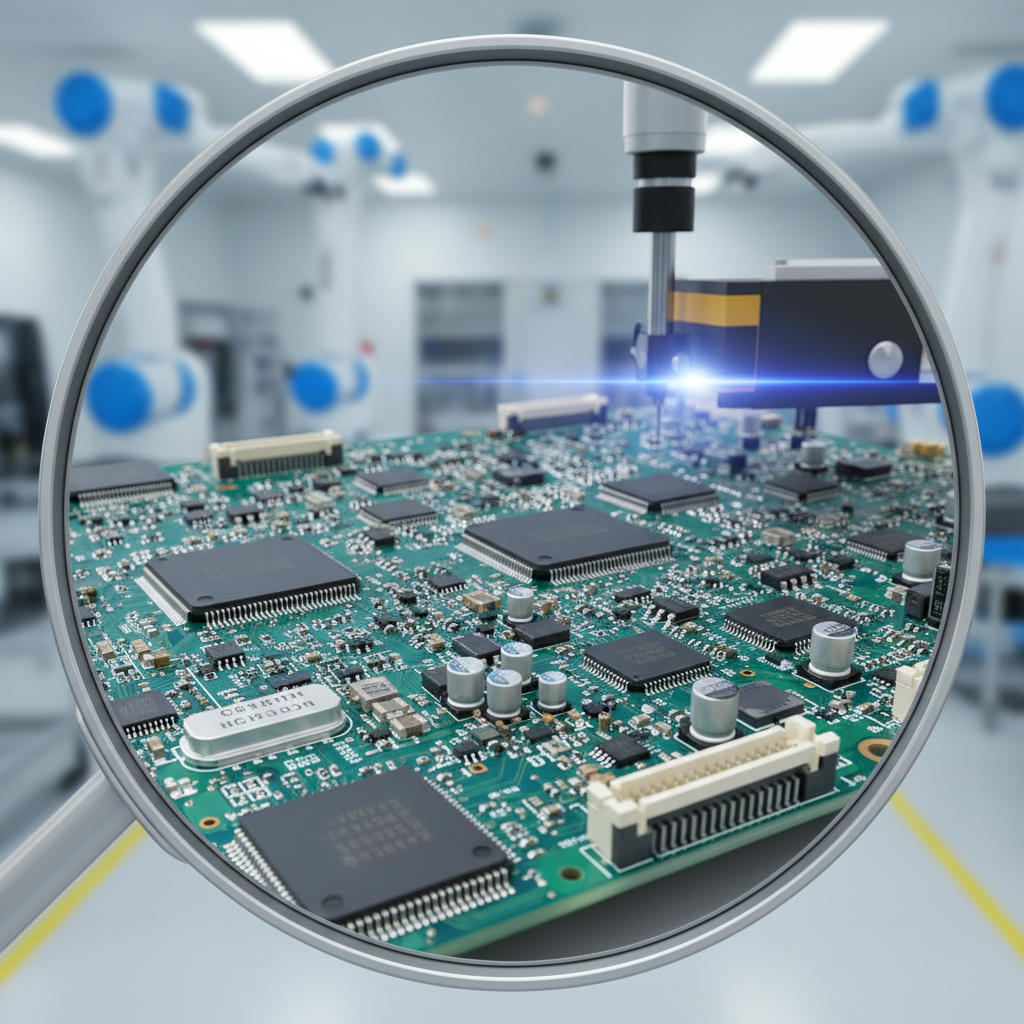

Printed Circuit Board Assembly (PCBA) is a vital process in the development of electronic devices, significantly enhancing both quality and reliability in circuit performance. According to a report by IPC, the global trade association for the electronics manufacturing industry, the failure rate of electronic assemblies can be reduced by as much as 30% when utilizing high-quality PCBAs. This improvement is largely due to advancements in manufacturing techniques and materials, which ensure better adherence and connectivity among components, leading to longer-lasting products.

Furthermore, a study by the International Electronics Manufacturing Initiative (iNEMI) highlighted that meticulously assembled PCBs can achieve a mean time between failures (MTBF) increase of up to 50% over poorly assembled alternatives. By employing precision assembly processes and rigorous quality control measures, manufacturers can test and verify functionality at multiple stages during production. As a result, businesses not only enhance the performance of their electronics but also significantly reduce costs associated with product recalls and repair services, solidifying the role of PCBA as a cornerstone in the electronics development ecosystem.

The process of Printed Circuit Board Assembly (PCBA) significantly enhances the efficiency of electronics projects, particularly in reducing the time to market. Industry research indicates that companies implementing streamlined PCBA processes can reduce their production timelines by up to 50%. This acceleration is crucial in a competitive electronics landscape, where technology evolves rapidly. The seamless integration of design and assembly in one workflow minimizes delays and miscommunication often experienced when multiple vendors are involved.

By utilizing advanced techniques such as automated assembly and simultaneous engineering, manufacturers optimize their operations, allowing for quicker prototyping and reduced turnaround times. A report from IPC, the global association for electronics manufacturing, reveals that companies leveraging automation in PCB assembly have observed a 30% increase in productivity and a marked reduction in human error. This not only improves the reliability of the final product but also supports a faster deployment, essential for staying ahead in the ever-evolving market.

Ultimately, the incorporation of efficient PCBA processes paves the way for increased innovation and responsiveness in electronic product development.

Printed Circuit Board Assembly (PCBA) offers extensive customization and prototyping support, which is essential for the success of electronics projects. When embarking on a new project, having the ability to tailor every aspect of the board—from the layout to the components—is crucial. This flexibility allows engineers to experiment with different designs and configurations quickly, enabling them to optimize the performance of their devices. Whether it’s adapting to specific industry standards or incorporating unique features, custom PCB designs cater to individual project requirements, ultimately leading to innovative solutions.

Moreover, the prototyping phase benefits greatly from effective PCBA services. Rapid prototyping allows for quick iterations, making it easier to identify potential issues early on. By working with a PCB assembly partner skilled in customization, developers can refine their concepts in real-time, ensuring that the end product meets functional and aesthetic expectations. This collaboration minimizes production delays and reduces costs, as prototypes can be tested and modified with efficiency. In an era where speed to market is vital, the combined advantages of customization and prototyping support in PCBA significantly enhance the development process for electronics projects.