30+ Years of Experience in PCB Design and Manufacturing

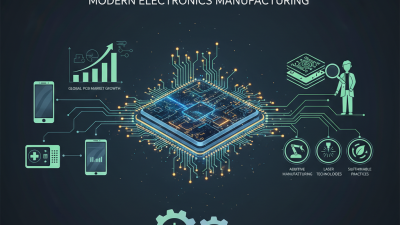

The landscape of PCB manufacturing is undergoing a transformative shift, driven by innovative technologies and evolving market demands. Recent reports indicate that the global PCB market is projected to reach $87 billion by 2025, with a compound annual growth rate (CAGR) of 4.5%. As industries increasingly rely on sophisticated electronics, the need for advanced printed circuit boards (PCBs) becomes imperative, underpinning the importance of understanding the trends shaping this sector.

Industry experts emphasize that innovation in PCB manufacturing processes, materials, and design capabilities will play a crucial role in meeting future demands. Dr. Emily Carter, a leading analyst in the PCB sector, has noted, “The future of PCB manufacturing lies in sustainability and smart technologies, which will redefine how we approach design and production.” This sentiment captures the essence of current trends, as manufacturers aim to implement eco-friendly practices while leveraging smart manufacturing principles to enhance efficiency and quality.

As we delve into the top trends of 2025, it is essential to explore how advancements in automation, IoT integration, and material science are poised to revolutionize PCB manufacturing. By embracing these innovations, the industry will not only meet the growing needs of various applications but also pave the way for a more sustainable and technologically advanced future.

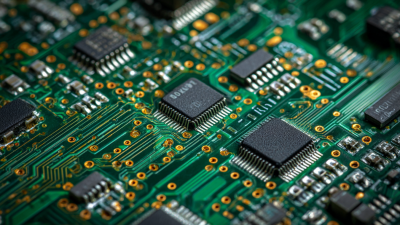

The PCB manufacturing industry is undergoing a significant transformation, driven by key innovations that are reshaping the future landscape. One of the standout trends is the increasing investment in automation and smart manufacturing technologies. According to a report by Mordor Intelligence, the global PCB market is expected to grow at a CAGR of 4.8%, reaching approximately $85 billion by 2025. This growth is largely attributed to advancements in automation that enhance production efficiency and reduce time-to-market, enabling manufacturers to meet the ever-increasing demand for high-quality printed circuit boards.

Another crucial innovation is the development of advanced materials, particularly in the realm of flexible PCBs and high-frequency laminates. As more devices require lightweight and compact designs, materials such as polyimide and low-loss dielectric substances are becoming essential in meeting these needs. Research by IPC indicates that the flexible PCB segment alone is projected to grow by over 10% annually through 2025, driven by applications in consumer electronics, automotive, and medical devices. These materials not only improve the performance of PCBs but also support the miniaturization trends that are a hallmark of modern electronic design.

Furthermore, sustainability is emerging as a pivotal consideration in PCB manufacturing. The push for eco-friendly manufacturing processes and recyclable materials is forcing companies to rethink their production methods. According to a study from SEMI, approximately 35% of PCB manufacturers are now investing in green technologies and sustainable practices. This shift is not just a response to regulatory pressures but a recognition of the importance of sustainable practices in appealing to both consumers and investors, ensuring the long-term viability of the industry.

Sustainable practices have emerged as a vital aspect of the PCB manufacturing industry, reshaping production processes and influencing the overall environmental footprint of electronic devices. With increasing awareness of climate change and resource depletion, manufacturers are adopting eco-friendly materials and techniques. The transition to water-based chemicals instead of traditional solvents, alongside the implementation of lead-free solder, showcases a growing commitment to reducing toxic waste and minimizing hazardous emissions.

Additionally, the adoption of circular economy principles is revolutionizing PCB production. Manufacturers are focusing on designing for disassembly and reusability, allowing components to be repurposed at the end of their lifecycle. This not only conserves resources but also reduces the volume of electronic waste entering landfills. Furthermore, advancements in recycling technologies are enabling more efficient recovery of precious metals and other materials from discarded PCBs, further promoting sustainability within the industry. As these initiatives gain traction, they exemplify how the integration of sustainable practices can lead to innovation while addressing the pressing environmental challenges of our time.

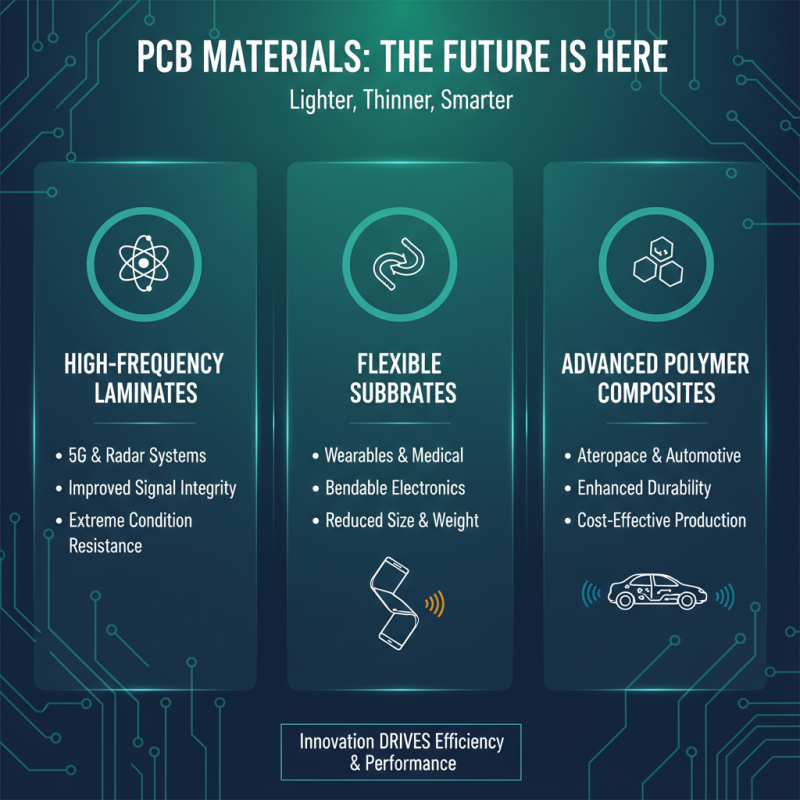

The landscape of PCB manufacturing is rapidly evolving, primarily driven by advancements in materials used for fabrication. In recent years, the demand for lighter, thinner, and more efficient products has prompted researchers and manufacturers to explore innovative materials that not only enhance performance but also reduce production costs. Emerging materials such as high-frequency laminates, flexible substrates, and advanced polymer composites are on the rise, enabling manufacturers to create PCBs that can withstand extreme conditions while maintaining electrical integrity.

One notable trend is the adoption of recyclable and environmentally-friendly materials as sustainability becomes a focal point in the industry. Manufacturers are increasingly incorporating bio-based resins and eco-friendly laminates into their production processes, reducing environmental impact while meeting the stringent demands of modern electronics. This shift not only responds to regulatory pressures but also aligns with consumer expectations for greener products. Additionally, advancements in nanomaterials and conductive inks introduce possibilities for creating compact designs that promote better thermal management and signal integrity, positioning manufacturers to meet future challenges head-on.

The integration of automation and artificial intelligence (AI) in PCB manufacturing is poised to redefine the industry landscape by 2025. According to a report by industry analysts, the global PCB market is expected to reach approximately $80 billion by 2025, with automation technologies contributing significantly to this growth. Automated processes enhance production efficiency, reduce errors, and streamline workflows, which is crucial in meeting the increasing demand for high-quality printed circuit boards in diverse applications such as consumer electronics, automotive, and medical devices.

AI plays a transformative role in optimizing PCB manufacturing processes. Through machine learning algorithms, manufacturers can analyze vast amounts of data to predict equipment failures, optimize production schedules, and improve quality control. A recent study indicates that AI implementation in manufacturing can lead to a reduction in operational costs by up to 30%, highlighting its potential for creating more cost-effective and competitive production environments. The synergy of automation and AI not only drives efficiency but also enables the rapid prototyping of designs, accelerating time-to-market for innovative products in an ever-evolving technology landscape.

| Trend | Description | Impact | Adoption Rate (%) |

|---|---|---|---|

| Automation in Manufacturing | Implementation of robotics to streamline production lines. | Increases efficiency and reduces labor costs. | 75% |

| AI for Quality Control | Using machine learning algorithms to detect defects in real-time. | Decreases error rates and improves product quality. | 60% |

| 4D Printing Technology | Development of PCBs that can change shape or properties over time. | Enhances functionality of electronic devices. | 30% |

| Sustainable Materials | Use of eco-friendly materials to manufacture PCBs. | Reduces environmental impact and appeals to eco-conscious consumers. | 50% |

| Internet of Things (IoT) Integration | Designing PCBs specifically for IoT devices. | Supports smarter manufacturing and connected devices. | 70% |

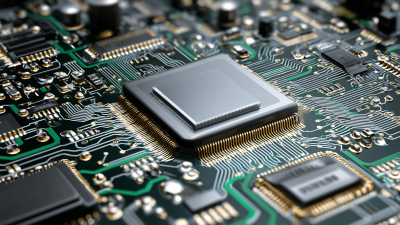

The landscape of PCB (Printed Circuit Board) design is evolving rapidly, influenced by technological advancements and the growing demand for high-performance electronics. According to a recent market report by Mordor Intelligence, the global PCB market is expected to reach approximately $78.35 billion by 2025, driven largely by innovations in automation and materials technology. As devices become smaller and more complex, the focus on enhancing performance and reliability through advanced design practices has never been more critical.

In response to these demands, designers are increasingly adopting new materials and methodologies that promote efficiency and durability. The shift towards multilayer boards, for instance, allows for higher component density while maintaining signal integrity. Furthermore, the integration of simulation tools and AI-driven design software is enabling engineers to create more reliable circuits by predicting failure points and optimizing layouts before production. This proactive approach not only accelerates the design process but also significantly reduces the risk of defects, aligning with the trend towards sustainability in electronics manufacturing.

Moreover, as the Internet of Things (IoT) continues to expand, PCBs are becoming integral to more intricate and interconnected systems. The acceptance of flexible PCBs across various applications, such as wearable technology and medical devices, highlights the industry's pivot towards versatility and adaptability. Research by TechNavio indicates that flexible PCBs are projected to grow at a CAGR of 11% through 2025, underscoring the need for designs that prioritize both performance and reliability in an increasingly complex electronic landscape.