30+ Years of Experience in PCB Design and Manufacturing

As we move closer to 2025, the landscape of circuit board assembly (CBA) is undergoing significant transformation driven by advancements in technology and evolving industry standards. The demand for faster production, higher precision, and increased efficiency is pushing manufacturers to adopt innovative practices that not only streamline operations but also enhance product quality. Industry expert Dr. Emily Chen, a leading figure in electronics manufacturing, emphasized, "To remain competitive in circuit board assembly, companies must embrace the latest technologies and refine their processes to meet the ever-changing market demands."

In this era of rapid innovation, several key trends are emerging that are set to shape the future of circuit board assembly. Automation and artificial intelligence are being increasingly utilized to improve efficiency and accuracy in assembly processes. Additionally, the integration of sustainable practices is becoming crucial, as companies seek to minimize their environmental impact while maximizing productivity. Understanding these trends is essential for professionals in the field, as they navigate the complexities of modern circuit board assembly practices.

This article explores the top trends and best practices that are expected to dominate the circuit board assembly industry in 2025. By addressing these innovations, stakeholders can position themselves for success in a competitive environment while meeting the demands of an ever-evolving technological landscape.

The circuit board assembly industry is poised for transformative changes in 2025, driven by emerging technologies that enhance efficiency and precision. One of the most significant advancements is the integration of artificial intelligence and machine learning, allowing for real-time monitoring and adaptive quality control processes. These technologies enable more accurate inspections during the assembly process, reducing defects and minimizing waste. By leveraging predictive analytics, manufacturers can anticipate potential issues before they arise, ensuring a smoother production workflow and higher reliability in the final products.

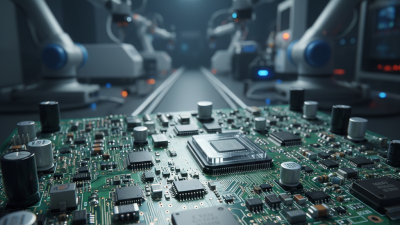

In addition to AI applications, advancements in automation are set to redefine assembly lines. Collaborative robotics, or cobots, are increasingly being utilized to assist human operators in tasks that demand precision and speed. These robots can work alongside human workers, improving productivity while maintaining safety standards. Furthermore, the implementation of Internet of Things (IoT) technologies allows for enhanced connectivity between machines and systems, enabling efficient data exchange and better resource management. The convergence of these innovations will not only streamline the manufacturing process but also foster a more flexible and responsive production environment, setting new benchmarks for the circuit board assembly industry in 2025.

The circuit board assembly industry is witnessing a significant shift towards sustainability, driven by increasing consumer awareness and regulatory pressures. Eco-friendly manufacturing practices are becoming essential as companies strive to reduce their environmental footprint. According to a recent industry report, about 60% of manufacturers are now implementing sustainable practices in their assembly processes, reflecting a growing commitment to greener operations.

Key innovations in eco-friendly circuit board manufacturing include the adoption of lead-free soldering techniques and the use of biodegradable materials. Switching to lead-free options not only minimizes health risks associated with toxic substances but also aligns with global regulations like the EU's RoHS directive. Additionally, advancements in material science have introduced alternative substrates derived from organic sources, further enhancing sustainability. A report from the Electronics Industry Citizenship Coalition indicates that utilizing these materials can reduce carbon emissions by up to 30%, demonstrating a tangible benefit of incorporating sustainable practices.

Moreover, the integration of recycling technologies in the circuit board assembly process optimizes waste management. A study by the International Electronics Recycling Foundation revealed that optimized recycling processes can recover over 90% of metals found in circuit boards. This not only contributes to the conservation of natural resources but also provides cost savings for manufacturers. As these trends continue to evolve, the commitment to sustainable practices in circuit board assembly will play a crucial role in the industry’s landscape.

| Trend | Description | Impact on Sustainability |

|---|---|---|

| Lead-Free Solder | Adoption of lead-free solder materials in assembly processes. | Reduces environmental contamination and health risks. |

| Flexible PCBs | Integration of flexible printed circuit boards (PCBs) for compact designs. | Minimizes waste by reducing the need for multiple boards. |

| Recyclable Materials | Utilization of materials that can be fully recycled after use. | Promotes circular economy and reduces landfill waste. |

| Energy-Efficient Manufacturing | Techniques to lower energy consumption during production. | Lowers carbon footprint of electronic devices. |

| Ethical Sourcing | Commitment to sourcing materials from responsible suppliers. | Supports fair labor practices and sustainable sourcing. |

The integration of automation and robotics in circuit board assembly processes is reshaping the manufacturing landscape, enhancing efficiency and precision. According to a recent report by the IPC (Institute for Printed Circuits), the adoption of automated systems is projected to increase productivity by up to 25% in the coming years. This trend is driven by the need for higher output and reduced labor costs, as manufacturers face increasing pressures to meet the demands of a rapidly changing electronics market.

Robotechnology plays a critical role in minimizing human error and improving quality control during assembly. A study from Deloitte indicates that manufacturers implementing advanced robotics in their production lines can achieve defect reduction rates of 90% or higher. Collaborative robots (cobots) are particularly effective in circuit board assembly, working alongside human operators to enhance tasks such as component placement and soldering. The agility and reliability that these robotic systems offer are crucial for handling the complex and delicate nature of modern circuit boards, which often involve intricate designs and smaller components.

Furthermore, the future of circuit board assembly will increasingly rely on smart automation technologies, utilizing artificial intelligence and machine learning to optimize assembly processes. These innovations not only streamline operations but also provide valuable data analytics that can inform strategic improvements, ensuring that manufacturers remain competitive in an ever-evolving industry. As these technologies continue to advance, they will play an essential role in shaping the productivity and capabilities of circuit board manufacturing in 2025 and beyond.

Quality control in circuit board production is crucial for ensuring reliability and efficiency in electronic devices. According to a report by the IPC (Association Connecting Electronics Industries), an estimated 20% of all electronic failures can be traced back to issues in circuit board assembly. As innovations in technology continue to transform the landscape, implementing robust quality control measures has become even more critical for manufacturers striving to maintain high standards.

One of the best practices for quality control includes the integration of automated optical inspection (AOI) systems, which can enhance defect detection rates. Recent studies indicate that utilizing AOI can improve defect detection by over 90%, thus significantly reducing rework costs. Additionally, adopting a comprehensive testing regimen throughout the assembly process—such as X-ray inspection for hidden solder joints—ensures that potential issues are identified early. The World Electronics Report highlights that companies focusing on proactive quality control strategies experience up to a 30% reduction in production downtime, reinforcing the importance of a meticulous approach in modern manufacturing processes.

The landscape of materials used in circuit board assemblies is evolving rapidly, driven by the need for enhanced performance, miniaturization, and sustainability. In 2025, we can expect to see several innovative materials gaining traction, such as advanced polymers and eco-friendly laminates. These materials not only provide better thermal stability and electrical performance but also align with the industry's growing commitment to environmental responsibility. As manufacturers seek to reduce their carbon footprint, the integration of biodegradable materials and low-impact production techniques is likely to become a common practice.

Tips: When selecting materials for your circuit board assemblies, prioritize those that meet both your technical requirements and sustainability goals. Conduct thorough research on the lifecycle impacts of the materials you consider to ensure they contribute positively to your product’s overall efficiency and environmental footprint.

Another anticipated advancement is the rise of nanomaterials in circuit board technology. By incorporating nanoparticles into traditional substrates, manufacturers can achieve improved conductivity and mechanical strength. This innovation not only enhances the performance of electronic devices but also promotes more efficient use of space, allowing for the creation of thinner and lighter components. Moreover, the trend towards 5G and IoT applications will further drive the adoption of these cutting-edge materials.

Tips: Stay informed about the latest research in nanomaterials and explore collaborations with suppliers who are pioneering these advancements. This proactive approach can give you a competitive edge in the rapidly evolving circuit board assembly market.

This chart illustrates the top trends in circuit board assembly for 2025, highlighting the adoption rate of various innovations such as eco-friendly materials, high-frequency PCBs, and flexible circuits.